I did something new today, used the FEL and the Q/A frame to hoist the harrow, WHILE also mowing. Didn't want to make two trips (1/2 mile), so mowed backing up, while also dragging the harrow. This gave me the option of lifting it clear up while going across my driveway and other areas not needing harrowed. This will be my new way to harrow, mower or not. Then I positioned (2% grade, down) 60' of drill pipe that captured my spring water, which originates 300' lower and 2000' away, and is pumped into a 2100 gallon storage tank at the highest end of my 70 acres. The tank has an overflow, and thanks to the fall of the property in 60' it exits the pipe about 5' off the ground. A water wheel, (using some 5' 100 year farm implement iron wheels), or a Japanese deer chaser, (a giant sized one, not of bamboo but 6 or 8" pipe)may be in the works, just as a hoot and also an easy to eyeball indication that the tank is full. With my "spring re-location" project in it's first summer, I have 3 to 4 K gallons of water to play with, every sunny day, and also am wrapping up an extensive irrigation project.

What did you do to or on your Kubota today?

- Thread starter gurn

- Start date

trial and error

Well-known member

Equipment

B7100dt manual trans. homemade FEL, 4 way hydraulic dozer blade

Moved this contraption out our wooded section this afternoon ,and staged it near some other junk headed for the scrap yard in a few weeks. still didn't put the counterweight back on so I was 3 wheelin it the whole way back up the hill. That old trailer axle doesn't weigh much, but it was enough to need 4wd in places I wouldn't normally if I had the weight on the back. Slow and steady is the name of the game when doing "dumb stuff"

Attachments

-

1,012.4 KB Views: 238

Last night when I was cutting grass with the Del Morino flail I heard a sound that made me think that the belts needed tightening. This morning I adjusted belt tension and greased all the fittings. The flail has twelve zerks if you include both ends of the pto shaft, and I'm a little concerned at how much grease the flail drum bearings needed (bottom zerk in the photo below). I've greased all the fittings regularly, but with the belt guard off and the flail raised up I kept pumping grease in until I saw signs that the bearings were full. I'm talking a lot of pumps of the handle. It's as if the bearings came dry from the factory and my regular greasing schedule never put enough grease into them.  After adjusting belt tension and running the flail I can hear that sound still, maybe not as loud but it's there. Oh well, worst case is that I need to replace the drum bearings if they're shot. Time will tell.

After adjusting belt tension and running the flail I can hear that sound still, maybe not as loud but it's there. Oh well, worst case is that I need to replace the drum bearings if they're shot. Time will tell.

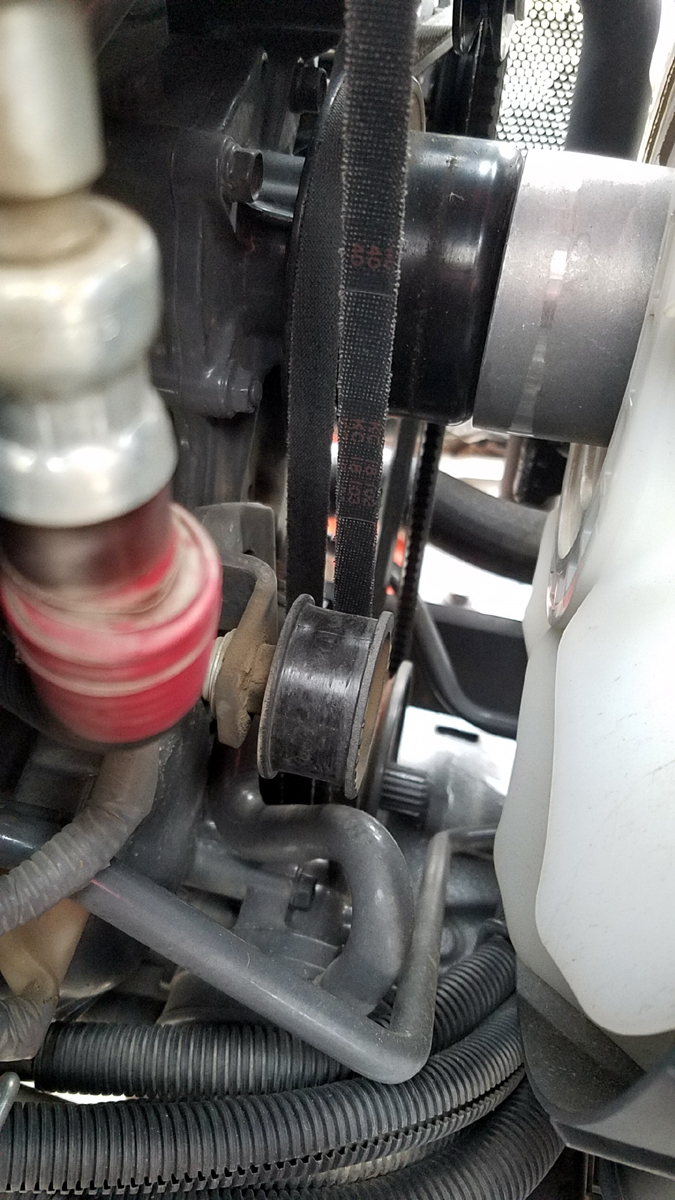

I bought a Radiator Genie from the local Kubota dealer yesterday and thought I'd blow out the MX's engine compartment to see how well it works. With the engine running I noticed that the A/C belt tensioner isn't rotating, which basically means that it isn't doing any tensioning. The belt feels reasonably tight though, and definitely tighter than the other belt that runs the water pump and alternator. Regardless, I'll need to adjust both. I remember that I had to tighten the belt on the MX6000 open station fairly early on in the 103 hours that I put on it becuase it was "chirping" on start up, but I don't think I've had to do it on this MX yet which has 130 hours on it.

The belt feels reasonably tight though, and definitely tighter than the other belt that runs the water pump and alternator. Regardless, I'll need to adjust both. I remember that I had to tighten the belt on the MX6000 open station fairly early on in the 103 hours that I put on it becuase it was "chirping" on start up, but I don't think I've had to do it on this MX yet which has 130 hours on it.

I bought a Radiator Genie from the local Kubota dealer yesterday and thought I'd blow out the MX's engine compartment to see how well it works. With the engine running I noticed that the A/C belt tensioner isn't rotating, which basically means that it isn't doing any tensioning.

What did the manual say? Did it say to grease or not to grease before first use? (My chipper specified not to grease before first use.)Last night when I was cutting grass with the Del Morino flail I heard a sound that made me think that the belts needed tightening. This morning I adjusted belt tension and greased all the fittings. The flail has twelve zerks if you include both ends of the pto shaft, and I'm a little concerned at how much grease the flail drum bearings needed (bottom zerk in the photo below). I've greased all the fittings regularly, but with the belt guard off and the flail raised up I kept pumping grease in until I saw signs that the bearings were full. I'm talking a lot of pumps of the handle. It's as if the bearings came dry from the factory and my regular greasing schedule never put enough grease into them.After adjusting belt tension and running the flail I can hear that sound still, maybe not as loud but it's there. Oh well, worst case is that I need to replace the drum bearings if they're shot. Time will tell.

View attachment 105539

View attachment 105540

I bought a Radiator Genie from the local Kubota dealer yesterday and thought I'd blow out the MX's engine compartment to see how well it works. With the engine running I noticed that the A/C belt tensioner isn't rotating, which basically means that it isn't doing any tensioning.The belt feels reasonably tight though, and definitely tighter than the other belt that runs the water pump and alternator. Regardless, I'll need to adjust both. I remember that I had to tighten the belt on the MX6000 open station fairly early on in the 103 hours that I put on it becuase it was "chirping" on start up, but I don't think I've had to do it on this MX yet which has 130 hours on it.

View attachment 105542

The Italian manual (see below) states to check the gearbox and grease before first use. I did both of those things and have greased the machine regularly. Have you ever pumped grease into a zerk and wondered where it's going? With most grease fittings you either hear, feel or see confirmation that the grease has got to where it needs to go. The end bearings for the main drum just kept taking grease this morning so now I'm thinking that they came dry and that I never put enough grease in them until today.What did the manual say? Did it say to grease or not to grease before first use? (My chipper specified not to grease before first use.)

Basically I'm not sure if the noise is the belts on the pulleys or the end bearings. I have the belt guard off and will run it tonight using the PTO override option and get close enough to determine where the noise is coming from. No doubt the safety police will disapprove.

So long as grease gun pumping / not out of grease…Yep I agree with you seems strange for sure….either leaks around zerk if not on correct or after a few pumps you feel it firm up and then oozes out somewhere…seems odd at best. The grease went somewhere…if came out anywhere there should be some residue with some dirt crusted in I would think?The Italian manual (see below) states to check the gearbox and grease before first use. I did both of those things and have greased the machine regularly. Have you ever pumped grease into a zerk and wondered where it's going? With most grease fittings you either hear, feel or see confirmation that the grease has got to where it needs to go. The end bearings for the main drum just kept taking grease this morning so now I'm thinking that they came dry and that I never put enough grease in them until today.

Basically I'm not sure if the noise is the belts on the pulleys or the end bearings. I have the belt guard off and will run it tonight using the PTO override option and get close enough to determine where the noise is coming from. No doubt the safety police will disapprove.

View attachment 105544

I’d make sure to put my hair up in a bun and take the neck tie off before putting ear up to it.

keep us posted.

I have had an excavator at the house for a few weeks.

Just cleaning up the mess,roots rocks and some dirt.

Now I need to repair the lawn.

Here is a picture of me getting rid of the mess

Just cleaning up the mess,roots rocks and some dirt.

Now I need to repair the lawn.

Here is a picture of me getting rid of the mess

Siesta Sundance

Well-known member

Lifetime Member

Equipment

L305DT, MX 5200, SVL 75-2, (Sold M7060))

I often use a wood broom(no plastic or metal ends) handle for a good stethoscope.The Italian manual (see below) states to check the gearbox and grease before first use. I did both of those things and have greased the machine regularly. Have you ever pumped grease into a zerk and wondered where it's going? With most grease fittings you either hear, feel or see confirmation that the grease has got to where it needs to go. The end bearings for the main drum just kept taking grease this morning so now I'm thinking that they came dry and that I never put enough grease in them until today.

Basically I'm not sure if the noise is the belts on the pulleys or the end bearings. I have the belt guard off and will run it tonight using the PTO override option and get close enough to determine where the noise is coming from. No doubt the safety police will disapprove.

View attachment 105544

Last edited:

I've used a long screwdriver more than a few times on an engine and driveline trying to locate a noise. I didn't get to confirm the source of the noise last night but will try this morning. For the record, I really like that Del Morino flail mower and would buy the same model again, or a bigger model. It's just so useful around my place getting into tighter areas, cutting banks, etc.I often use a wood broom(no plastic or metal ends) handle for a gpod stethoscope.

Moved the LX outta the way so I could use the table saw as well as back my truck into the shop to work on a tail-light that's taking on water. But, since it was out, cut a few low-hanging branches and used the grapple to drop them on top of the 'habitat' piles out back. Beyond that, about all I did was burn my bacon on a VERY hot seat. Note to self: There's more than one reason to tilt the seat forward..

I hauled the M60 and rotary cutter over to a friend's place late yesterday afternoon and started cutting his field. What with the rain and disturbing fawns in the 3ft high grass it was less than ideal. I quit early, had dinner with my friends and left the tractor and trailer at his place last night. It's another wet morning here so I'll most likely pick up the tractor today and finish cutting his fields in a couple of weeks when I'm back from vacation.

There's always a learning curve and this trailer is no exception. I had hoped to be able to pull the tractor forward more but the tongue weight is excessive. The other sketchy thing is driving on/off the trailer. It's quite the incline and because the cable for the remote doesn't reach to the back of the trailer I had to drive on with the deck at full tilt, apply the parking brake, get out and then lower the deck. This morning I grabbed the remote cable from one of the dump trailers in the hope that I can extend the remote cable on this deckover trailer until I install the wireless remote kit.

There's always a learning curve and this trailer is no exception. I had hoped to be able to pull the tractor forward more but the tongue weight is excessive. The other sketchy thing is driving on/off the trailer. It's quite the incline and because the cable for the remote doesn't reach to the back of the trailer I had to drive on with the deck at full tilt, apply the parking brake, get out and then lower the deck. This morning I grabbed the remote cable from one of the dump trailers in the hope that I can extend the remote cable on this deckover trailer until I install the wireless remote kit.

Last edited:

Nice looking property. Definitely sounds like a pucker factor getting on and off the trailer. Wireless is the way to go, I could see me ripping the wires offI hauled the M60 and rotary cutter over to a friend's place late yesterday afternoon and started cutting his field. What with the rain and disturbing fawns in the 3ft high grass it was less than ideal. I quit early, had dinner with my friends and left the tractor and trailer at his place last night. It's another wet morning here so I'll most likely pick up the tractor today and finish cutting his fields in a couple of weeks when I'm back from vacation.

There's always a learning curve and this trailer is no exception. I had hoped to be able to pull the tractor forward more but the tongue weight is excessive. The other sketchy thing is driving on/off the trailer. It's quite the incline and because the cable for the remote doesn't reach to the back of the trailer I had to drive on with the deck at full tilt, apply the parking brake, get out and then lower the deck. This morning I grabbed the remote cable from one of the dump trailers in the hope that I can extend the remote cable on this deckover trailer until I install the wireless remote kit.

View attachment 105731

View attachment 105732

View attachment 105733

That’s a nice set up for sure. I wanted a roll back I. The worst way, but…watching the dealer that picks up and drops off using one I did not have the confidence….they feel a lot steeper than they look and I was too concerned I would get caught in rain rush to get out of rain and id slip/crack head open. My dealer driver walks up and down it like a Billy goat…I think as you use it regularly it will exceed a regular deck over. The convenince of them undeniable though.I hauled the M60 and rotary cutter over to a friend's place late yesterday afternoon and started cutting his field. What with the rain and disturbing fawns in the 3ft high grass it was less than ideal. I quit early, had dinner with my friends and left the tractor and trailer at his place last night. It's another wet morning here so I'll most likely pick up the tractor today and finish cutting his fields in a couple of weeks when I'm back from vacation.

There's always a learning curve and this trailer is no exception. I had hoped to be able to pull the tractor forward more but the tongue weight is excessive. The other sketchy thing is driving on/off the trailer. It's quite the incline and because the cable for the remote doesn't reach to the back of the trailer I had to drive on with the deck at full tilt, apply the parking brake, get out and then lower the deck. This morning I grabbed the remote cable from one of the dump trailers in the hope that I can extend the remote cable on this deckover trailer until I install the wireless remote kit.

View attachment 105731

View attachment 105732

View attachment 105733

johnjk

Well-known member

Lifetime Member

Equipment

B3200 w/loader, Woods RC5 brush hog, 4' box blade, tooth bar, B1700 MMM,

Garden cleanup with the big B and mowing with the little B.

Attachments

-

701.9 KB Views: 212

-

1 MB Views: 208

My snow pusher came in today. Got it back home. Decided to test something with it. Been wanting a box blade. Just to help smooth out the driveway after laying 45 yards of class II. Held off buying the box blade until I tested my idea With the pusher. It works great leveling off the high spots. Don’t need a box blade anymore. My wallets screamed ouch paying for it but it will earn its keep.