Interesting. I learned something new today.I just moved the Mini in & out of the backyard yesterday, spinning it in its own length each time.

The area is 3"-4" dp in 1" minus granite. I went out & checked and found these rocks pushed thru from the inside. (not staged)

The rest of the holes appeared clear.

View attachment 82531

Hanix Mini Giant excavator?

- Thread starter Lil Foot

- Start date

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

So did I. In retrospect, it's one of those DOH! revelations that is so obvious -- once it is explained!

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Sigh... got all the replacement zerks installed, and pumped some grease in.... and then found this crushed line, complete with hole in it.

Crap.

I will be heading to the local HosePower store later today to see if they have a 6mm hose coupler, in either compression or swagelok.

Can't figure out how it got crushed where it is located, unless they drove over a big branch or something and jammed it up under the house.

Crap.

I will be heading to the local HosePower store later today to see if they have a 6mm hose coupler, in either compression or swagelok.

Can't figure out how it got crushed where it is located, unless they drove over a big branch or something and jammed it up under the house.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

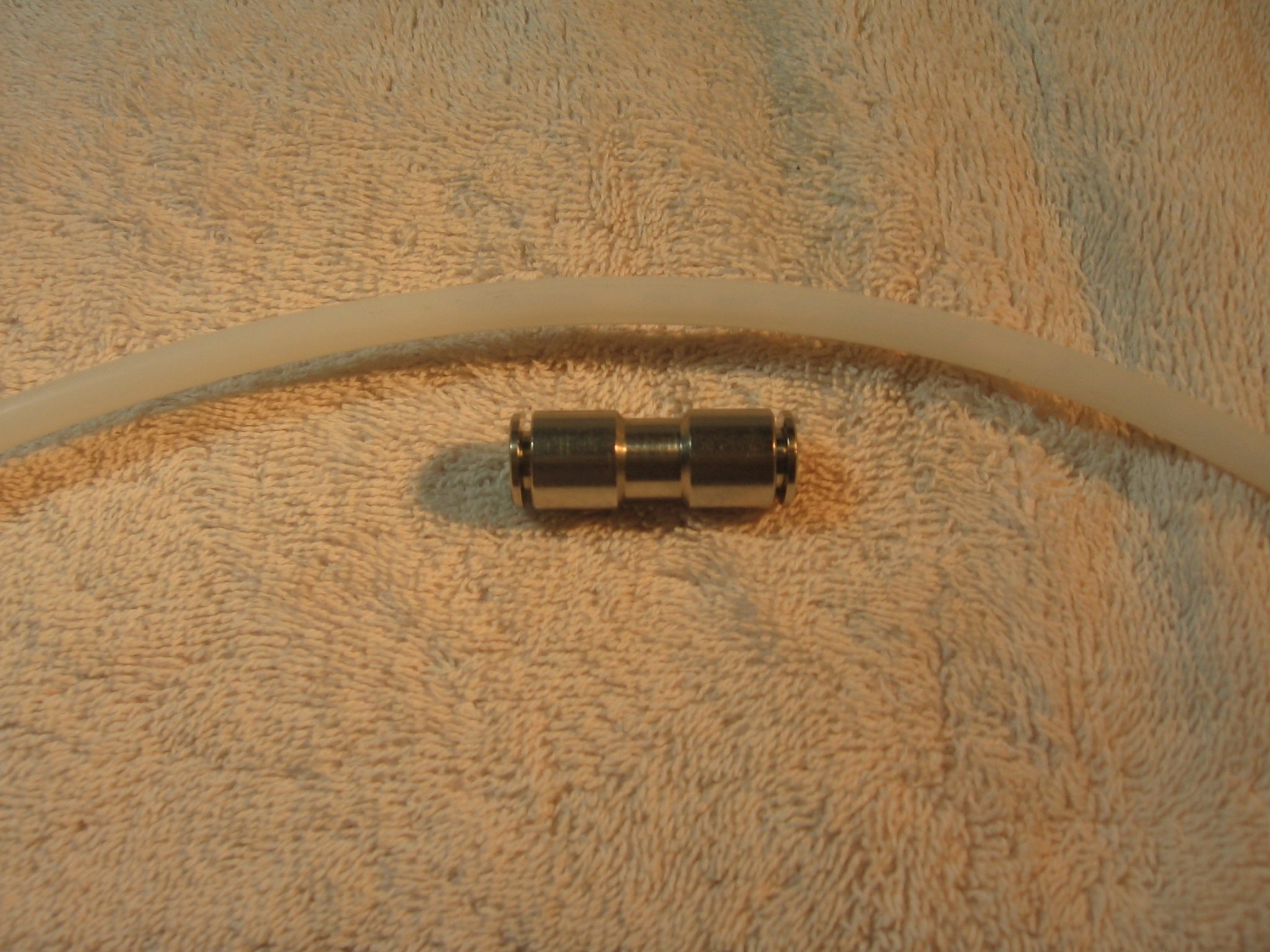

Got some 6mm heavy poly hose, and push-to-connect unions.

Would have preferred swagelok or even compression, but nothing available (in 6mm) on my side of the valley.

Hose rated at 250psi, unions at 400psi, more than enough for open-end grease lines.

After installation, I locked the unions by slipping/stretching o-rings over the fittings and into the groove, so the "release" cannot be pressed by a random stick or the like.

Grease now flowing as it should.

Just realized I didn't wipe the middle zerk clean. I'm disappointed in myself.

Would have preferred swagelok or even compression, but nothing available (in 6mm) on my side of the valley.

Hose rated at 250psi, unions at 400psi, more than enough for open-end grease lines.

After installation, I locked the unions by slipping/stretching o-rings over the fittings and into the groove, so the "release" cannot be pressed by a random stick or the like.

Grease now flowing as it should.

Just realized I didn't wipe the middle zerk clean. I'm disappointed in myself.

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

I removed the boom cylinder and dropped it off at a hydraulic cylinder specialist- they come highly recomended, but not cheap. We shall see how much that costs & how long it takes.

Upper pin shows virtually no wear, just some polished spots, so it will be re-used.

Lower pin, however, shows moderate wear.

Next step, got see if any of the local steel suppliers stock any 30mm barstock.

I think I'm going to need a bunch.

Kinda of amazed, looks like all the pins have replaceable bushings and wiper seals.

Didn't expect that on an old mini.

Upper pin shows virtually no wear, just some polished spots, so it will be re-used.

Lower pin, however, shows moderate wear.

Next step, got see if any of the local steel suppliers stock any 30mm barstock.

I think I'm going to need a bunch.

Kinda of amazed, looks like all the pins have replaceable bushings and wiper seals.

Didn't expect that on an old mini.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Been researching materials for pins and bushings and found several references to bronze bushings & even plastic bushings.

Examples:

Near as I can tell under all that crud, all the pins & all the bushings in the mini are steel.

I'm guessing whatever I use will probably outlast me, but I thought I'd solicit some opinions.

I will probably buy some 1144 stress proof for the pins, assuming I can find it in 30mm dia- that will save a bunch of machining.

If I use mild steel, I may have enough on hand to make all the bushings.

If I use some combination of plastic or bronze. I might have enough of those also.

I am almost tempted to make some of each and see what works.

Opinions?

Examples:

I'm guessing whatever I use will probably outlast me, but I thought I'd solicit some opinions.

I will probably buy some 1144 stress proof for the pins, assuming I can find it in 30mm dia- that will save a bunch of machining.

If I use mild steel, I may have enough on hand to make all the bushings.

If I use some combination of plastic or bronze. I might have enough of those also.

I am almost tempted to make some of each and see what works.

Opinions?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

DOM tube is great for bushings, faster and easier than turning your own. For my loader, I used 1" DOM tube and 1" cold rolled for the pins. I drilled the pins for grease nipples, turned a shallow groove in the centre and cross-drilled the pin at the groove to ensure distribution of the grease.Been researching materials for pins and bushings and found several references to bronze bushings & even plastic bushings.

Examples:

Near as I can tell under all that crud, all the pins & all the bushings in the mini are steel.

I'm guessing whatever I use will probably outlast me, but I thought I'd solicit some opinions.

I will probably buy some 1144 stress proof for the pins, assuming I can find it in 30mm dia- that will save a bunch of machining.

If I use mild steel, I may have enough on hand to make all the bushings.

If I use some combination of plastic or bronze. I might have enough of those also.

I am almost tempted to make some of each and see what works.

Opinions?

If you choose to go with bronze then 660 bearing bronze would be my choice.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Pulled the bucket & bucket pins off & cleaned them up. Damn.

The way this is supposed to work is with a set of 30mm holes on the boom, with a hub that has an 8mm cross hole for a bolt. (1st pic)

This keeps the pin from turning in the holes, so that all the wear in on the bushings in the moving part of the joint. Theoretically.

(rest of the pics)

The pins are toast, and the hubs on the bucket are toast, and the 30mm holes are all wallowed out.

One hub on the bucket is gone completely, and the other is so thin and wallowed out, I will probably just cut it off & start over from scratch for both hubs.

The way this is supposed to work is with a set of 30mm holes on the boom, with a hub that has an 8mm cross hole for a bolt. (1st pic)

This keeps the pin from turning in the holes, so that all the wear in on the bushings in the moving part of the joint. Theoretically.

(rest of the pics)

The pins are toast, and the hubs on the bucket are toast, and the 30mm holes are all wallowed out.

One hub on the bucket is gone completely, and the other is so thin and wallowed out, I will probably just cut it off & start over from scratch for both hubs.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

You didn't buy an excavator -- you bought an excavator kit -- some additional parts required, batteries not included.

Like someone earlier, I just joined because of your project. I have an N-21 Mini Giant that I purchased probably 12 years ago. Very similar to your machine but a little bigger (and cleaner! That thing was filthy). I had the same rotted battery tray but relocated it to a plastic battery box under the seat. It’s been reliable, but I have the same pin/bushing wear. I opened that can of worms when I decided to build a ditch cleaning bucket. I just rebuilt 4 leaking cylinders, and rewelded a couple pins. I think Ill just buy the bushings and pins for the end of the dipper. Cheaper than the time spent machining new ones.

Nice to see someone else keeping one of these running.

Nice to see someone else keeping one of these running.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Wow, and the hits just keep on coming.....

From an earlier post:

"I removed the boom cylinder and dropped it off at a hydraulic cylinder specialist- they come highly recomended, but not cheap. We shall see how much that costs & how long it takes."

Original estimate $300-350, 1 week lead time.

Tomorrow will be two weeks since I dropped it off.

Found out the day I dropped it off, the "small cylinder specialist" took a piece of metal in the eye because he didn't have his safety glasses on.

He came back yesterday and tore down my cylinder to inspect it & give me an estimate.

Estimate came in at $1012.00! (choke sputter gasp!) 12-15 day lead time.

They say the ram is bent (slightly) and has some nicks, so it needs to have the ram cut off, a new one machined, then re-welded, then all the seals/wipers replaced.

I told them this is 1/3 what I paid for the machine, and was there an alternative?

They said they could straighten the ram, polish the nicks, & rebuild it, but with no warranty, for $526.00!

5-10 day lead time.

They looked for a new substitute cylinder, with no luck.

I looked for a new substitute cylinder, with no luck.

When I told them to box it up and maybe I'll just scrap the excavator, they asked me to wait until tomorrow when the owner comes in. They said maybe he can do better on the price, because he hates to turn anyone away.

So I will see what he has to say. Maybe I will go the no warranty route.

From an earlier post:

"I removed the boom cylinder and dropped it off at a hydraulic cylinder specialist- they come highly recomended, but not cheap. We shall see how much that costs & how long it takes."

Original estimate $300-350, 1 week lead time.

Tomorrow will be two weeks since I dropped it off.

Found out the day I dropped it off, the "small cylinder specialist" took a piece of metal in the eye because he didn't have his safety glasses on.

He came back yesterday and tore down my cylinder to inspect it & give me an estimate.

Estimate came in at $1012.00! (choke sputter gasp!) 12-15 day lead time.

They say the ram is bent (slightly) and has some nicks, so it needs to have the ram cut off, a new one machined, then re-welded, then all the seals/wipers replaced.

I told them this is 1/3 what I paid for the machine, and was there an alternative?

They said they could straighten the ram, polish the nicks, & rebuild it, but with no warranty, for $526.00!

5-10 day lead time.

They looked for a new substitute cylinder, with no luck.

I looked for a new substitute cylinder, with no luck.

When I told them to box it up and maybe I'll just scrap the excavator, they asked me to wait until tomorrow when the owner comes in. They said maybe he can do better on the price, because he hates to turn anyone away.

So I will see what he has to say. Maybe I will go the no warranty route.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

That is Oscar. Pictured below before his copper paint job. He has a sliding door on his underside, to stash a spare key. Sometimes we find him turned over with the door opened, like we would leave a key there. Morons.

He also has company, (directly behind the mini) a large light blue doggo, that is actually a birdseed feeder. Could not find a pic of him.

Edit:

Found a long range pic of doggo:

Attachments

-

743.1 KB Views: 194

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

I considered it briefly, but could not find anything close, and I need more machining projects like I need another hole in my head. With having to machine custom pins & bushings for up to 16 locations, my dance card is full.I would think with your machining capabilities, you could purchase a new aftermarket cyl and adapt it to your needs for a lot less.

I would also probably have to have custom hoses made up to adapt the SAE thread cylinder to the as yet un-identified metric threads on the mini.

That’s just nuts. I just rebuilt 4 cylinders on my machine. The boom ram has some nicks in it as well, I just polished the surface so there are no sharp edges to cut the wiper or seal. When I went to reassemble the bucket cylinder, the gland nut was binding. There was a slight bend in the ram. I put it in V-blocks on my shop press and straightened it (just visually, no dial indicator) it went back together fine. Seals for the 4 I rebuilt came to $267. They’re all back together and they’re all liquid tight. I thought I recall someone saying the hyd fittings are BSP thread.I considered it briefly, but could not find anything close, and I need more machining projects like I need another hole in my head. With having to machine custom pins & bushings for up to 16 locations, my dance card is full.

I would also probably have to have custom hoses made up to adapt the SAE thread cylinder to the as yet un-identified metric threads on the mini.

BAP

Well-known member

Lifetime Member

Equipment

2012 Kubota 2920, 60MMM, FEL, BH65 48" Bush Hog, 60"Backblade, B2782B Snowblower

Would it be worth getting a second quote from a different shop? Even though that place is highly recommended, sometimes those types of places are also the most expensive.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

This image shows the boom cylinder mounts?

What is the spacing between the bushings? Stroke length? Cylinder length? Cylinder diameter?

With all the DIY types on this forum, I bet someone could find a cylinder similar enough, especially since you are making new bushings anyway.

What is the spacing between the bushings? Stroke length? Cylinder length? Cylinder diameter?

With all the DIY types on this forum, I bet someone could find a cylinder similar enough, especially since you are making new bushings anyway.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

EG (just guessing at an approximate size):

Here is a 3" diameter, 20" stroke cylinder. Pin diameter 1" (25mm), base pin eye width 3-3/4", rod pin eye width 2-1/4", retracted length 28" pin to pin. ORB -08 female fittings. CDN$239. I'm sure US pricing on something similar is much less.

Eye widths can be shimmed or shaved, bushings made to suit, ORB adapters to suit the hoses. Don't give up now!!! This is discouraging, perhaps. Especially with all the other pressures you have right now, but there's light at the end of the tunnel! Hang in there buddy.

Here is a 3" diameter, 20" stroke cylinder. Pin diameter 1" (25mm), base pin eye width 3-3/4", rod pin eye width 2-1/4", retracted length 28" pin to pin. ORB -08 female fittings. CDN$239. I'm sure US pricing on something similar is much less.

Eye widths can be shimmed or shaved, bushings made to suit, ORB adapters to suit the hoses. Don't give up now!!! This is discouraging, perhaps. Especially with all the other pressures you have right now, but there's light at the end of the tunnel! Hang in there buddy.