joekimtkd

New member

Equipment

B7510DT, 4' Snow blower, 4' Loader, 6' Blade, 6' 3PH Finish mower, 6' box blade,

Welcome Paul~! I knew you would come...Joe I have three auto shade welding helmets here at the shop. They all have there place and all have been great to use. One thing I have found with some of the older ones is that condensation can cause them to flick in and out once in awhile. My shop is full of florescent lights but I personally haven't had any ill effects because of them in my shop. They never bothered my helmets while welding.

I will add that I believe you get what you pay for in a helmet. The ones I use are in or above the $200. mark but have always given me great service. The newest helmet which is about a year old now is a Miller DIGITAL ELITE Inferno design. Great helmet and I love the X-mode but the helmet do get a little heavy after a few hours use. The condensation don't bother this one either.

I wonder where is the Ed and Rusty and John~???

My helmet works fine. Auto shade and all. Just my stupid mask that I'm wearing collects all the humid from my breath and throw it out to welding helmet and fogs up the display window and can't see anything~

I have to invent new wiper that cleans my helmet display window~

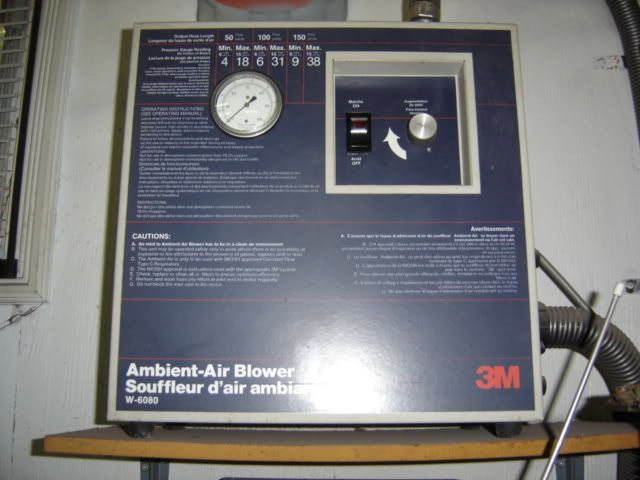

I'm sure I wanted to use respirator to save my lung and nasal path.

I can't wait till I go to Princess auto to buy that respirator...

Don't you guys using any respirator when you welding~~~????????

Joe.