Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

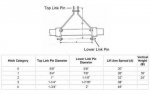

This is the pin that would go into the top arm (the ones that actually are moved by the tractor hydraulics)

http://www.tractorpartsinc.com/images_products/lower_lift_arm_link_pin_7408big.jpg

A vertical lift rod similar to this would then slide over the pin and be held in place with a lynch pin

http://www.brokentractor.com/admin/files/parts/SBA370200220a.jpg

This lets the lower arms move in or out as needed without putting any torque into the upper arm.

When looking around I did see some pictures similar to what you have so maybe I am just plain wrong.

How do you install an implement? It seems you would have to remove the vertical arms to get enough sideways movement of the lower arms to go over the pins on the implement.

http://www.tractorpartsinc.com/images_products/lower_lift_arm_link_pin_7408big.jpg

A vertical lift rod similar to this would then slide over the pin and be held in place with a lynch pin

http://www.brokentractor.com/admin/files/parts/SBA370200220a.jpg

This lets the lower arms move in or out as needed without putting any torque into the upper arm.

When looking around I did see some pictures similar to what you have so maybe I am just plain wrong.

How do you install an implement? It seems you would have to remove the vertical arms to get enough sideways movement of the lower arms to go over the pins on the implement.