I have live in a rural area with two brothers nearby each on their own well.

One brother frequently has nieces and nephews staying over and wanting to use water at same time.

Because I am an old engineer I am expected to solve all family technical issues.

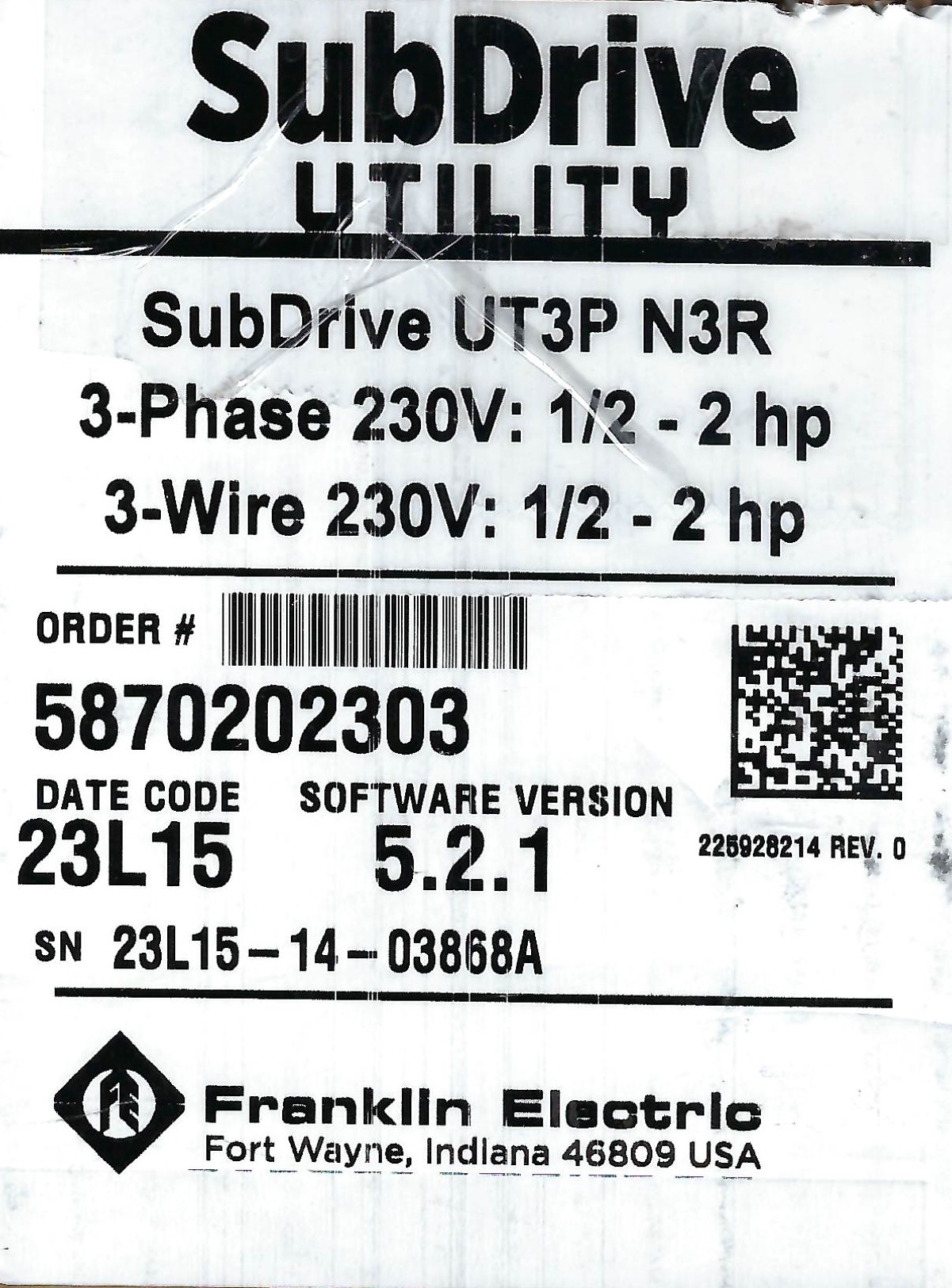

Franklin Electrics new Sub drive utility to the rescue.

You need a 3 wire submersible pump. Red, Yellow, Black and Green as ground.

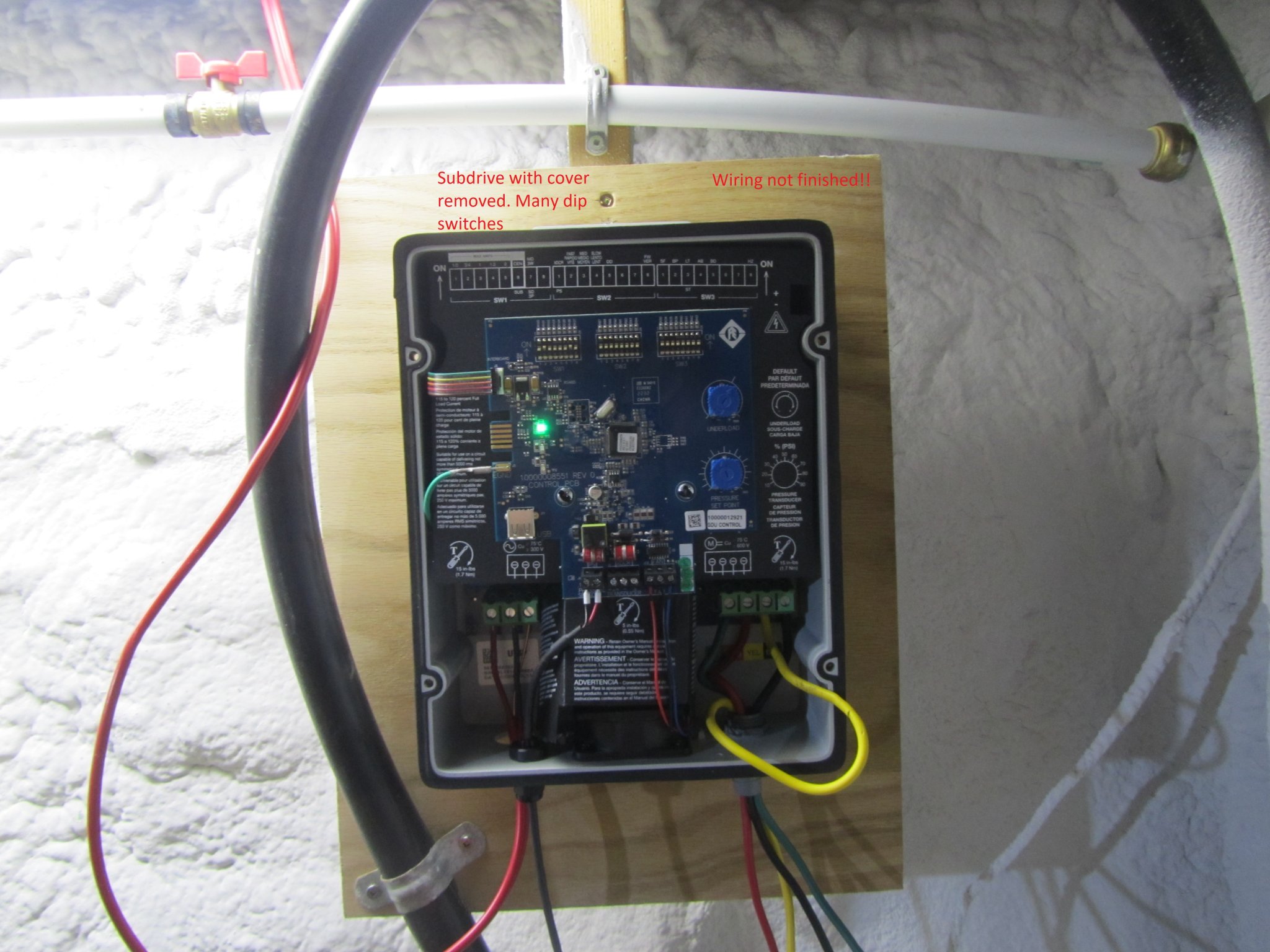

The sub drive replaces the previous control box with a capacitor and relay. No need to go into the well

The Subdrive turns your existing pump into variable speed pump. In effect your single phase pump becomes a 3 phase variable speed pump.

In this configuration the home water pressure remains high and stable. Previously it was on at 40 psi and off at 60 psi.

Now it maintains a steady 72 psi.

Previously I had a small 5 micron filter before a UV sterilization system but there was so much pressure drop through this filter I replaced it with one 4.5" x 20"

In Canada the subdrive was $1,500 + tax.

Dave

One brother frequently has nieces and nephews staying over and wanting to use water at same time.

Because I am an old engineer I am expected to solve all family technical issues.

Franklin Electrics new Sub drive utility to the rescue.

You need a 3 wire submersible pump. Red, Yellow, Black and Green as ground.

The sub drive replaces the previous control box with a capacitor and relay. No need to go into the well

The Subdrive turns your existing pump into variable speed pump. In effect your single phase pump becomes a 3 phase variable speed pump.

In this configuration the home water pressure remains high and stable. Previously it was on at 40 psi and off at 60 psi.

Now it maintains a steady 72 psi.

Previously I had a small 5 micron filter before a UV sterilization system but there was so much pressure drop through this filter I replaced it with one 4.5" x 20"

In Canada the subdrive was $1,500 + tax.

Dave