Well, to be honest I have some of them too. Might be fun to start a thread where we all can post those half done projects!dang HOW do you stay FOCUSED on just one project ??

Amazing....

somehow I end up with 10-15 '1/2 done' projects here....

Farmall H restoration

- Thread starter Yooper

- Start date

Ktrim

Well-known member

Equipment

B2400, lA352 loader,3pth quick hitch/z122r zero turn/restored 52 farmall super a

New valves, springs, keepers and new valve guides installed plus a three angle valve grind and the head is complete. I haven't done a three angle valve grind since high school auto shop so that was a trip down memory lane.

Working on buttoning up the bottom end. One of the parts is the rear main seal housing that holds the felt seals. This is one area that I think IH came up a little short on the engineering side. It seems like this part was an afterthought and I'm not the first person to say this. The housing is made out of cast aluminum that is really thin in areas. A lot of warpage and pockets when I ran a dial indicator across the gasket surfaces. No way am I going to try and machine this so down to the surface plate with an eighty grit sanding disc to level it out. Worked it until my shoulder gave out but I am satisfied that it will seal.

Got it installed but it was no fun. Quite a wrestling match with the engine stand in the way. Then on went the oil pan and a good feeling getting a lot of parts back in place!

For years I had looked into buying a granite surface plate but the shipping charges always killed the deal. Then a few years ago, a supplier sent me a notice of an 8 hour flash sale that included free shipping on anything but their largest equipment (some dimensional restrictions applied but there were no weight restrictions in the ad).Working on buttoning up the bottom end. One of the parts is the rear main seal housing that holds the felt seals. This is one area that I think IH came up a little short on the engineering side. It seems like this part was an afterthought and I'm not the first person to say this. The housing is made out of cast aluminum that is really thin in areas. A lot of warpage and pockets when I ran a dial indicator across the gasket surfaces. No way am I going to try and machine this so down to the surface plate with an eighty grit sanding disc to level it out. Worked it until my shoulder gave out but I am satisfied that it will seal.

View attachment 114754 View attachment 114755 View attachment 114756

View attachment 114757

I quickly ordered and paid for a 12 x 18 Grade B surface plate!

They are one of the handiest items you can have in your shop for all kinds of checking, testing, and building.

I want to clean up the tappets because they had some wear pockets in them. I got this idea in my head to do it on the surface grinder with a profiled wheel. Now, surface grinding is the operation I have the least amount of time invested in so this was going to be a challenge.

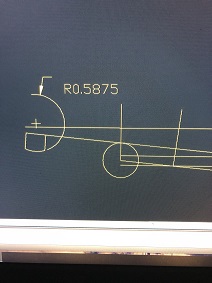

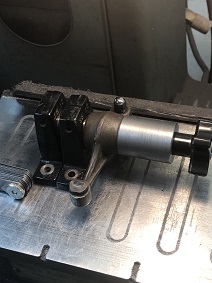

First I have to figure out the radius of the tappet and I did so on autocad by measuring and using data from the manual. Then I ordered a 1" wide wheel off of ebay for a reasonable price and got it mounted and balanced. Then I came up with a way to set up my 5c milling fixture with a way to profile the wheel with a diamond tip and set the radius on my surface plate. Profiled the wheel and visually checked it by holding a tappet to the wheel and it looks like I nailed it.

First I have to figure out the radius of the tappet and I did so on autocad by measuring and using data from the manual. Then I ordered a 1" wide wheel off of ebay for a reasonable price and got it mounted and balanced. Then I came up with a way to set up my 5c milling fixture with a way to profile the wheel with a diamond tip and set the radius on my surface plate. Profiled the wheel and visually checked it by holding a tappet to the wheel and it looks like I nailed it.

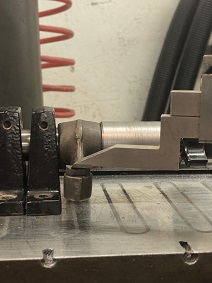

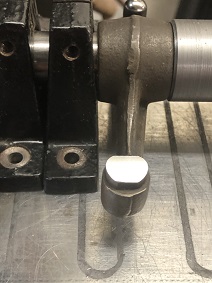

I rigged up a simple fixture for holding the rocker arm and indicated it in so the rockers would be parallel to the shaft. Then with the indicator I established the height of the tappet end so they would be ground level. By using my height gauge it allowed for accurate repeatability. Took my time with the grinding and they all cleaned up really nice. The final touch was polishing on the buffer to get a mirror finish. Couldn't be happier with the way it all went!

Rebuilding the water now. Disassembled and determined that the impeller shaft, packing nut and bearing nut need to be replaced. Also the bushings that the impeller shaft run on which is shown here.

Made a new impeller shaft which was pretty easy. The only thing was that the shaft had a tapered pin through the impeller which I didn't notice until I pressed it apart. Replaced it with a larger pin.

Making a new packing nut out of a piece of Ampco aluminum bronze. A lot of wasted material because of the size of the stock but what the heck, I got it for nothing and it is a perfect use for this material. I did it in two steps on the lathe because I had to come up with a way to cut the hex on the mill.

Making a new bearing retainer nut because the grease seal rides on the surface. Used a piece of 1045 stock and used the same procedure I did with the packing nut. Even though I have a parts manual, I didn't look up the pump before ordering the seals. This pump takes two seals and I only ordered one. But its not like I don't have anything to do while waiting for the second seal!

Nice work. Is the grease fitting to actually get grease to the bearing or to keep water from the bearing?

There are two grease fittings. One is for the fan hub bearings and if you over grease them the grease would just go by the seals and to the outside. IOW, no harm except the mess. The other grease fitting goes to the bushings that the impeller shaft runs on which is independent from the fan hub. It is driven by a 'lathe dog thingy' attached to the fan hub. There is a packing that seals the coolant from leaking. If you over grease this fitting it will introduce grease to the cooling system by the impeller. Good question!Nice work. Is the grease fitting to actually get grease to the bearing or to keep water from the bearing?

Made some miscellaneous parts for the water pump. New caps for the grease fittings out of brass. These grease fittings don't have the little check ball in them. This is to allow grease to escape rather than go into the cooling system. Next is a lock bolt for the driver for the impeller shaft. Then I finished with two new drive studs for the impeller shaft. Made those out of tool steel. Will assemble the water pump tomorrow.

Ktrim

Well-known member

Equipment

B2400, lA352 loader,3pth quick hitch/z122r zero turn/restored 52 farmall super a

Again never cease to amazeMade some miscellaneous parts for the water pump. New caps for the grease fittings out of brass. These grease fittings don't have the little check ball in them. This is to allow grease to escape rather than go into the cooling system. Next is a lock bolt for the driver for the impeller shaft. Then I finished with two new drive studs for the impeller shaft. Made those out of tool steel. Will assemble the water pump tomorrow.

View attachment 116332 View attachment 116333 View attachment 116334

View attachment 116335 View attachment 116336

Water pump is buttoned up and on to the carburetor. During disassembly, the venturi, which is a separate part, got damaged due to being corroded in place. Had to use heat to get it out of the casting. Never made a carburetor venturi before so I took it on as a challenge. First thing I did was chuck it up in the lathe and set the angle of the compound for the upper end.

Then dug around in the scrap pile and found a piece of aluminum and off we go!

Then dug around in the scrap pile and found a piece of aluminum and off we go!