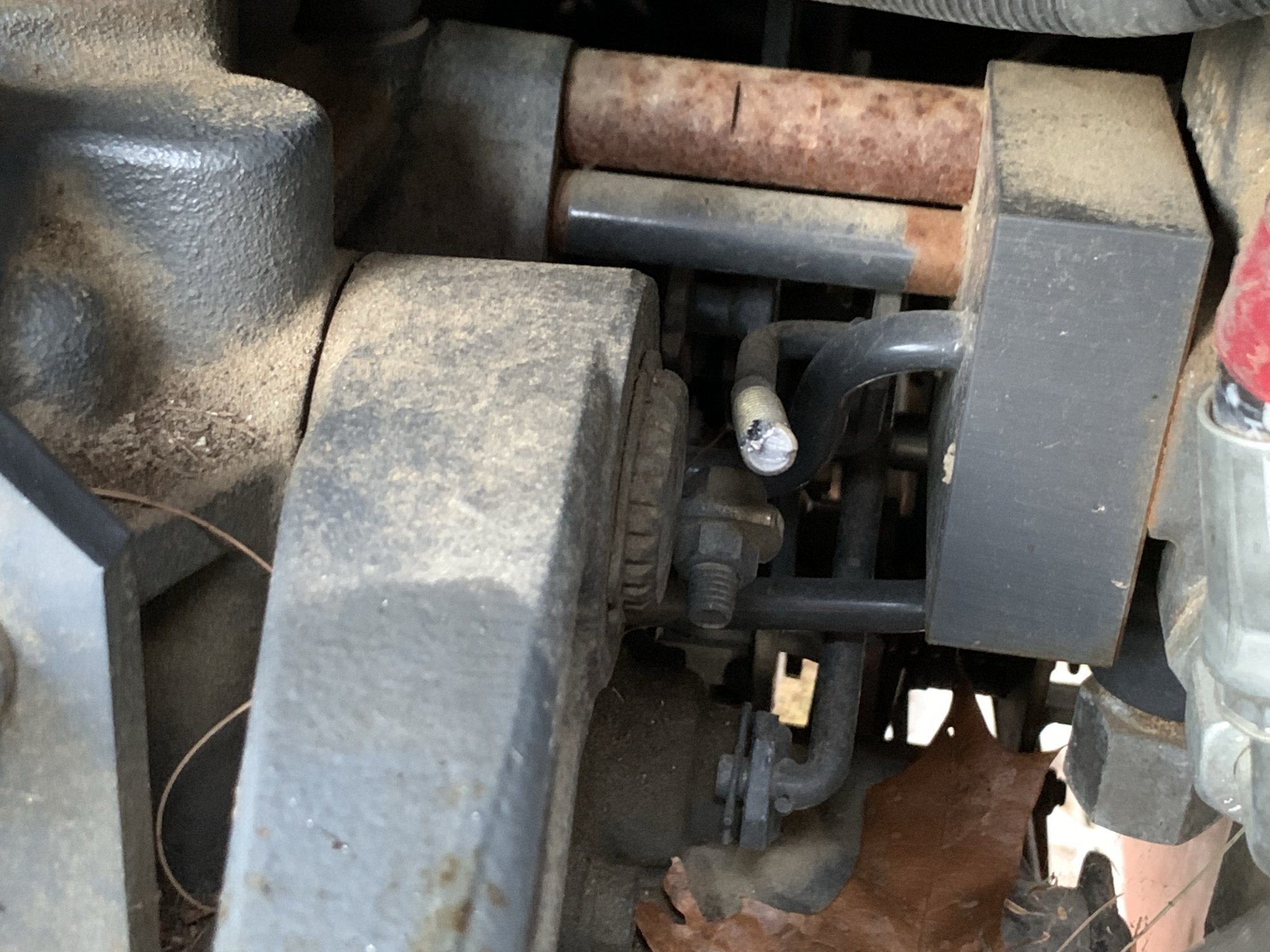

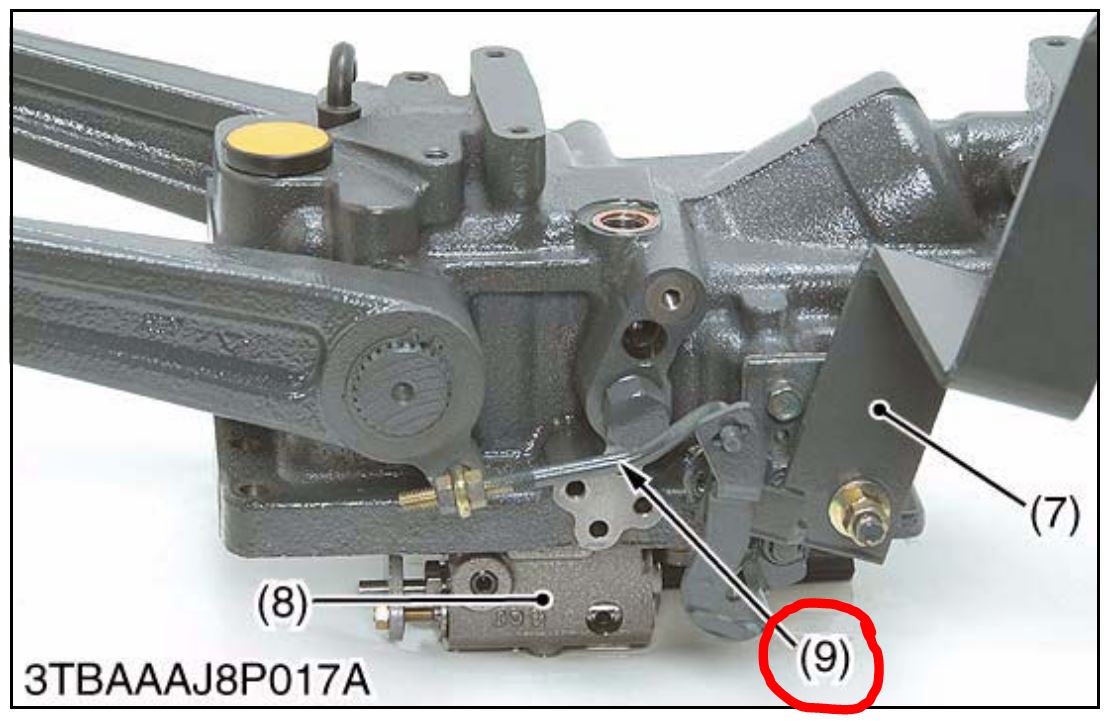

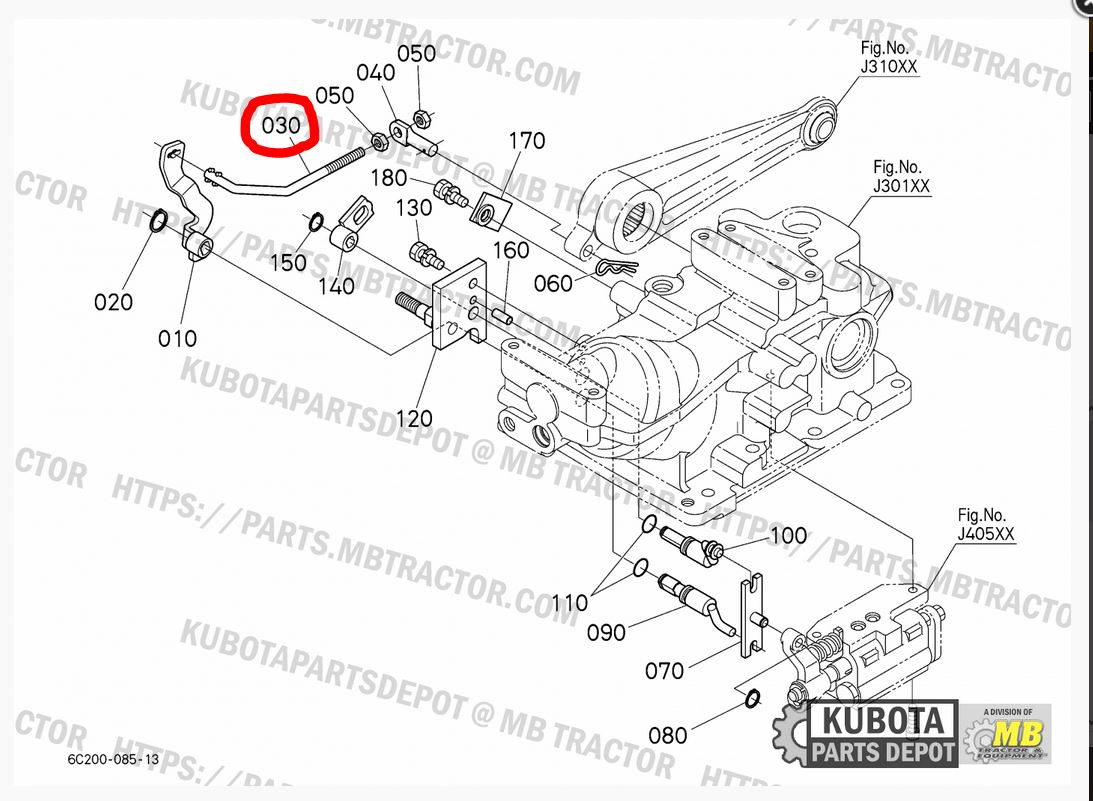

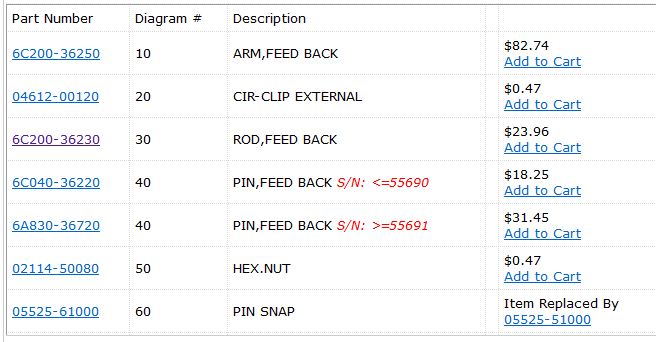

I found that the "Feedback Arm" controlling the three point hitch is broken. I have ordered a new one and have two questions:

(1) Why would this break? Is there a lot of load on it or is this a symptom of another issue?

(2) Any tips on replacement?

Thanks,

- Josh

(1) Why would this break? Is there a lot of load on it or is this a symptom of another issue?

(2) Any tips on replacement?

Thanks,

- Josh