Hello everyone! I'm new here and have been looking through the site for some time now. I recently purchased a 1987 B7200D and am thrilled to have a Kubota diesel!

I have been learning how to understand the hydraulic system and recently the clutch/throw out bearing etc. Certainly a learning curve!

I am not afraid to tackle things and figure it out, nor am I afraid to ask questions which is why I am here!

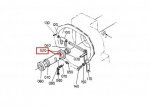

I split the tractor today to replace the throwout bearing that was making noise and found the pilot bushing to be somewhat dubious! I will order a new one but the stupid question I have is, that there was a brass/bronze bushing that was seated into the flywheel opening that was rather shredded and I cut it out. I'm pretty sure that the pilot bushing fits into the end of the crankshaft, but what is this other bushing called? I cannot find a part number for either of those parts on the Kubota.ca website. Also, do you have to remove the flywheel to install the pilot bushing?

Now, the input shaft has some wear near the "shoulder" close to the splines. What is considered acceptable wear on the shaft? Or, is the wear considered unacceptable and should it be replaced?

Thanks for considering my questions!

I have been learning how to understand the hydraulic system and recently the clutch/throw out bearing etc. Certainly a learning curve!

I am not afraid to tackle things and figure it out, nor am I afraid to ask questions which is why I am here!

I split the tractor today to replace the throwout bearing that was making noise and found the pilot bushing to be somewhat dubious! I will order a new one but the stupid question I have is, that there was a brass/bronze bushing that was seated into the flywheel opening that was rather shredded and I cut it out. I'm pretty sure that the pilot bushing fits into the end of the crankshaft, but what is this other bushing called? I cannot find a part number for either of those parts on the Kubota.ca website. Also, do you have to remove the flywheel to install the pilot bushing?

Now, the input shaft has some wear near the "shoulder" close to the splines. What is considered acceptable wear on the shaft? Or, is the wear considered unacceptable and should it be replaced?

Thanks for considering my questions!