hello everyone.

i bei bought a used B7100 with an FEL..

IT started, that the 3pt. didn t move Up only without load and helping hands.

Long Story Short..

After useing search i changed Fluid and Filter. Cleaned the 2 Side Filters left n right.

And changed the O ring in the Hydraulik cylinder in the Back of the 3pt.

Now or moves with a little load to the top but with me on it would t move Up...

The screw for the Speed folrom the 3pt is adjusted and the handle under the Seat is also in the right Position (Arrow faceing to the left when younsit in the Seat).

Now i m in the way to Upgrade/replace the Hydro Pump and in that Case i m think about to Change the Hydro distribution Blocks...

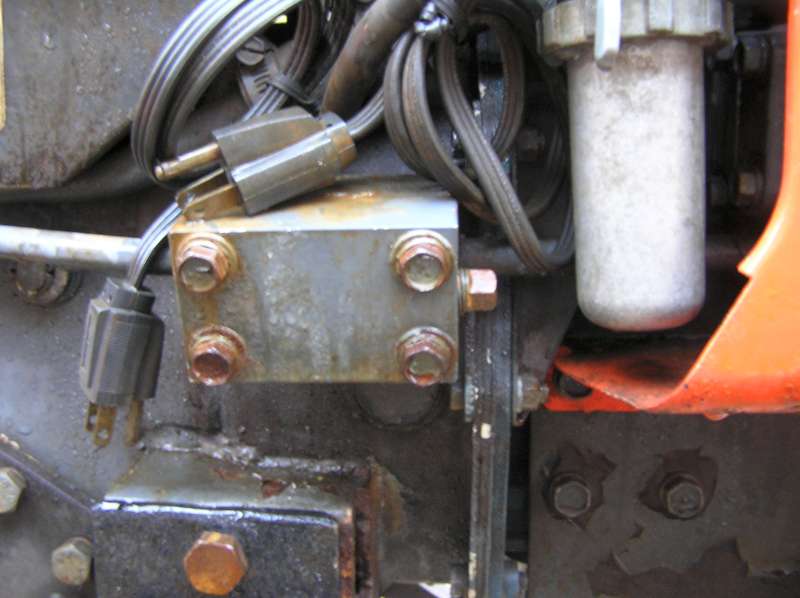

I think the owner before massed a little bit

around...

I m Not a pro in Hydro but i can Figure it Out that it IS very unusual solved...

Question:

Do you Pictures of your hydraulic that i can Check what i need and what Not?

I have a FEL with the 3 BG3 connector on the top Front.

The 3pt fies from the inner Block Back

And there are 2 hoses going Back for some extra stuff on also in BG3 connectors.

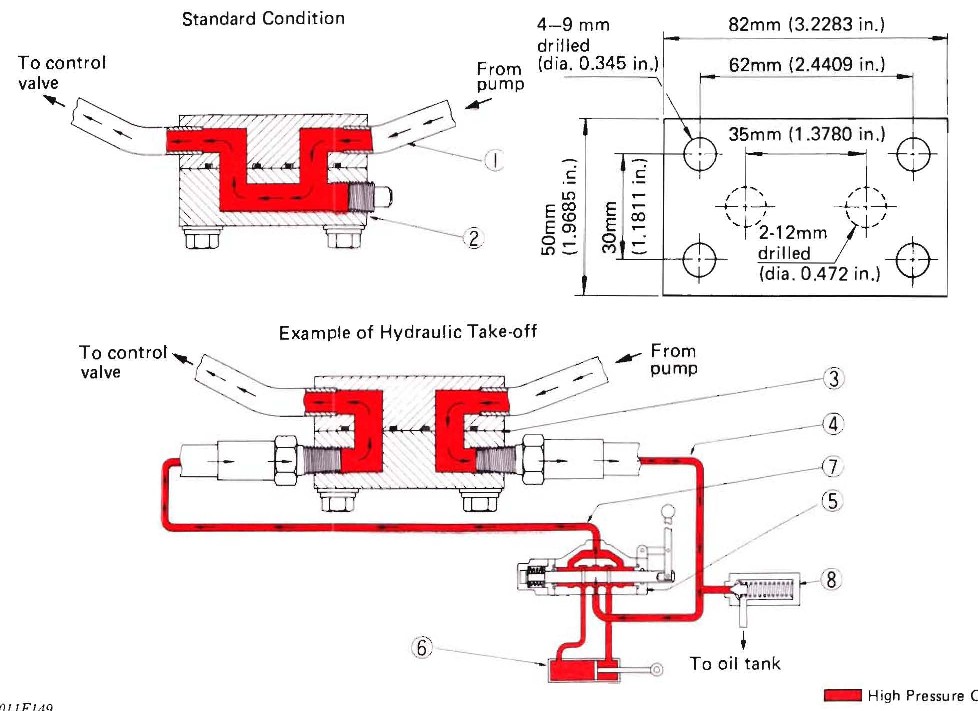

My Plan was buying this https://hydrotechnik24.de/steuerven...uyJ1ODzshxh0bXcfXxkFClGAgUPX642AaAoPYEALw_wcB

And Connect the FEL on 2 of the groups. The Last is for the 2 lines in the Back and the 3pt is going over the forwarding Output.

If some question are Open ASK

Is that right?

Could you Help me with my Problem?

Best regards

Para

i bei bought a used B7100 with an FEL..

IT started, that the 3pt. didn t move Up only without load and helping hands.

Long Story Short..

After useing search i changed Fluid and Filter. Cleaned the 2 Side Filters left n right.

And changed the O ring in the Hydraulik cylinder in the Back of the 3pt.

Now or moves with a little load to the top but with me on it would t move Up...

The screw for the Speed folrom the 3pt is adjusted and the handle under the Seat is also in the right Position (Arrow faceing to the left when younsit in the Seat).

Now i m in the way to Upgrade/replace the Hydro Pump and in that Case i m think about to Change the Hydro distribution Blocks...

I think the owner before massed a little bit

around...

I m Not a pro in Hydro but i can Figure it Out that it IS very unusual solved...

Question:

Do you Pictures of your hydraulic that i can Check what i need and what Not?

I have a FEL with the 3 BG3 connector on the top Front.

The 3pt fies from the inner Block Back

And there are 2 hoses going Back for some extra stuff on also in BG3 connectors.

My Plan was buying this https://hydrotechnik24.de/steuerven...uyJ1ODzshxh0bXcfXxkFClGAgUPX642AaAoPYEALw_wcB

And Connect the FEL on 2 of the groups. The Last is for the 2 lines in the Back and the 3pt is going over the forwarding Output.

If some question are Open ASK

Is that right?

Could you Help me with my Problem?

Best regards

Para

Attachments

-

250.1 KB Views: 672

-

217.8 KB Views: 246

-

249.8 KB Views: 253

-

267.8 KB Views: 240

-

301.1 KB Views: 242

Last edited: