I picked up a b6100 a week or so ago and want to add a front end loader on it. I plan to build it myself and have a few questions. Number one is what kind of lift capacities an I expect? Second is do will the pump off the back of the injection pump run a loader? No need to be fast but need it to function. And last do I need to add an auxiliary tank for hydraulic fluid? Any info would be greatly appreciated|

B6100 front end loader hydraulics

- Thread starter Billkrummel

- Start date

If you're building the loader yourself the lifting capacity will be limited to a large extent by your loader design and the cylinders used. My L2501 is rated at about 1200 pounds. The B series, being a smaller tractor, would likely lift less. The tractor's hydraulic system powers my loader as should yours. My reservoir is located inside the body of the tractor and holds several gallons of fluid. Yours should require no auxiliary reservoir.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

The most common FEL on the B5100/6100/7100 series is the B219. It's rated lift capacity is 500 lbs.

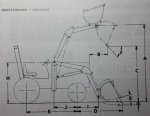

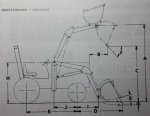

It uses a hydraulic pump driven off the crankshaft at the front of the engine, with the right hand upright serving as a tank. Keep in mind you willl need a subframe to connect the front & rear halves of the tractor, otherwise you invite disaster. Below are some pics & a set of dimensions that I put together for another member who built his own loader.

It uses a hydraulic pump driven off the crankshaft at the front of the engine, with the right hand upright serving as a tank. Keep in mind you willl need a subframe to connect the front & rear halves of the tractor, otherwise you invite disaster. Below are some pics & a set of dimensions that I put together for another member who built his own loader.

Thank you for all the information. I did not know about the subframe situation so I will be sure I get that right! Looking at it it makes perfect sense. I have read some information that Kubota sells a block for the b6100s that would allow you to tap into the hydraulic pump already on it and I have seen a few videos where it looks like that what others have done, so I'm gonna look into that before adding another pump.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Yup, I understand they can be a little hard to find, but their only drawback is slower operation compared to the crank driven pump.Kubota sells a block for the b6100s that would allow you to tap into the hydraulic pump already on it

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

I did a lot of calculations of lift capacity, dump angles, lift heights, etc. when I built mine (for the very similar B7100) 5 years ago. The thread is here. My target was 500 lbs in the bucket (ie: not including the weight of the bucket and arms). I ended up using 2" diameter cylinders 16" long (for both lift and curl). Cycle time to lift the arms from the ground to maximum and then back to ground worked out to 16 seconds tapping into the 3ph system hydraulic block with the OEM pump.

Smaller diameter cylinders would speed that up proportionally, but at the cost of flimsier rams. My thought at the time was to simply lower the FEL control relief valve setting to limit the maximum lift capacity (by lifting a 45 gallon drum of water while adjusting the relief setting), however I discovered that approach had the unintentional side-effect of limiting the 3ph lift capacity as well. 1-1/2" diameter cylinders might have been a better choice, being less likely to overload the front axle and taking less time to cycle.

Besides the effect of cylinder diameter on both weight capacity and speed, less obvious is the distance of the bucket in front of the tractor. Too far forward and the load on the front axle increases dramatically. Not far enough impacts the ability to dump onto a pile instead of the tractor hood. The rule-of-thumb I found during my research is that the distance between the back of the bucket on the ground and the front of the front tire should be about the same as the diameter of the front tire.

If you are interested, the actual build was photographed and documented here.

Smaller diameter cylinders would speed that up proportionally, but at the cost of flimsier rams. My thought at the time was to simply lower the FEL control relief valve setting to limit the maximum lift capacity (by lifting a 45 gallon drum of water while adjusting the relief setting), however I discovered that approach had the unintentional side-effect of limiting the 3ph lift capacity as well. 1-1/2" diameter cylinders might have been a better choice, being less likely to overload the front axle and taking less time to cycle.

Besides the effect of cylinder diameter on both weight capacity and speed, less obvious is the distance of the bucket in front of the tractor. Too far forward and the load on the front axle increases dramatically. Not far enough impacts the ability to dump onto a pile instead of the tractor hood. The rule-of-thumb I found during my research is that the distance between the back of the bucket on the ground and the front of the front tire should be about the same as the diameter of the front tire.

If you are interested, the actual build was photographed and documented here.

wow torch your build has already helped a ton and i haven't even started yet!

i didn't see any pictures of sub frame as lil foot mentioned is that because the 7100 is built different, or is it not a big concern? or is it because yours is 4x4?

i didn't see any pictures of sub frame as lil foot mentioned is that because the 7100 is built different, or is it not a big concern? or is it because yours is 4x4?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

I do have a sub-frame as it were. But rather than starting with the complete sub-frame, I started with the tower support and then added the bracing to the rear axle afterwards. I made brackets that bolt to the rear axle and connected each bracket to the tower supports with 1" heavy-wall square tube initially.

I later laminated a second length of tube on top of each initial one based on suggestions by lil foot and others. I believe they are as strong or stronger -- yet lighter in weight -- than thick pieces of flat bar. They get added in around page 3 of the build photos. I did the same for the braces from the towers to the front bumper.

I later laminated a second length of tube on top of each initial one based on suggestions by lil foot and others. I believe they are as strong or stronger -- yet lighter in weight -- than thick pieces of flat bar. They get added in around page 3 of the build photos. I did the same for the braces from the towers to the front bumper.

ok I see now. how many inches of travel did your lift cylinders have? I am looking at a set that have 14.25 inches but I'm not sure it will be enough. I plan to measure on my build to be sure before I buy anything but a ball park would be nice to know.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

My cylinders are all 16" of travel. IIRC, that is the same as or very similar to Kubota's B219. That is not to say you cannot make shorter cylinders work, but the shorter the cylinder, the more leverage that must be applied to get the same travel and the harder it is to be smooth in operation.

To illustrate by extreme thought experiment, 4" long rams used as a lift cylinders would have to be placed very near the pivot point between the lift arms and the support towers instead of supporting the arms midway, near the bend. So the towers and arms would have to be made of much heavier, stronger material to lift the same load. The cylinders would have to be much fatter diameter to apply the necessary force. So much so, that I doubt there is physically enough room to mount such a fat cylinder.

Placement of the cylinders is crucial. The angle has a huge impact on the actual lifting force that is applied. For example, a 2" bore cylinder fed with 1700 psi, mounted at 10° from horizontal will exert a vertical lifting force of 927lbs per cylinder at the fulcrum point (ie: the attachment point on the arms). But mounted at a 5° angle, the vertical force drops to 465lbs per cylinder. At 15°, the vertical force leaps to 1382lbs.

If the attachment point is exactly 1/2 way along the arm, then the true lifting force "at the pin" (attachment point of the bucket) is 1/2 the force at the fulcrum. Of course, the lifting force at the cutting edge (lip) of the bucket is notably less and also the lifting force has to lift the weight of the FEL components as well as the material in the bucket.

I found an on-line hydraulics angle calculator like this one to be invaluable during the design phase.

Ideally, you want the lowest point of travel for a flat bucket to be between 1" and 3" below grade (You can't dig unless the bucket can be lower than the wheels!). The highest point of travel should leave the lip of the bucket in the fully dumped position forward of the front of the tractor (you don't want to dump the load on your own hood!). I set mine up so the lip of the fully raised and dumped bucket is a few inches forward of the back of the bucket when flat on the ground.

The leverage effect also means the maximum height of the arms is extremely sensitive to the mounting point of the cylinder ends on the support columns. An inch difference in mounting height on the columns might mean a foot difference in lift height at the bucket.

In summary then: Yes, you can probably make 14-1/2" cylinders work if you carefully account for all the variables and can accept the resulting compromises. I have focused on the lifting arms in all of the above, but similar considerations come into play with the curl cylinders. That said, it is my gut feeling that one would require fewer compromises using shorter curl cylinders than required to use shorter lift cylinders because the lever lengths are much shorter in the curl geometry.

To illustrate by extreme thought experiment, 4" long rams used as a lift cylinders would have to be placed very near the pivot point between the lift arms and the support towers instead of supporting the arms midway, near the bend. So the towers and arms would have to be made of much heavier, stronger material to lift the same load. The cylinders would have to be much fatter diameter to apply the necessary force. So much so, that I doubt there is physically enough room to mount such a fat cylinder.

Placement of the cylinders is crucial. The angle has a huge impact on the actual lifting force that is applied. For example, a 2" bore cylinder fed with 1700 psi, mounted at 10° from horizontal will exert a vertical lifting force of 927lbs per cylinder at the fulcrum point (ie: the attachment point on the arms). But mounted at a 5° angle, the vertical force drops to 465lbs per cylinder. At 15°, the vertical force leaps to 1382lbs.

If the attachment point is exactly 1/2 way along the arm, then the true lifting force "at the pin" (attachment point of the bucket) is 1/2 the force at the fulcrum. Of course, the lifting force at the cutting edge (lip) of the bucket is notably less and also the lifting force has to lift the weight of the FEL components as well as the material in the bucket.

I found an on-line hydraulics angle calculator like this one to be invaluable during the design phase.

Ideally, you want the lowest point of travel for a flat bucket to be between 1" and 3" below grade (You can't dig unless the bucket can be lower than the wheels!). The highest point of travel should leave the lip of the bucket in the fully dumped position forward of the front of the tractor (you don't want to dump the load on your own hood!). I set mine up so the lip of the fully raised and dumped bucket is a few inches forward of the back of the bucket when flat on the ground.

The leverage effect also means the maximum height of the arms is extremely sensitive to the mounting point of the cylinder ends on the support columns. An inch difference in mounting height on the columns might mean a foot difference in lift height at the bucket.

In summary then: Yes, you can probably make 14-1/2" cylinders work if you carefully account for all the variables and can accept the resulting compromises. I have focused on the lifting arms in all of the above, but similar considerations come into play with the curl cylinders. That said, it is my gut feeling that one would require fewer compromises using shorter curl cylinders than required to use shorter lift cylinders because the lever lengths are much shorter in the curl geometry.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

I forgot to mention one other consideration: the lift arms travel in an arc. Assuming that a vertical line drawn through the lift cylinder mounting points (the fulcrum) is 1/2 way between the centerline of the bucket and the support columns when the bucket is on the ground, as the arms are raised, the bucket centerline moves out forward away from the fulcrum while the fulcrum itself moves inwards towards the support columns. Effectively, the leverage is reduced as the bucket is raised. Yes, the lift cylinder angle is becoming closer to vertical as the bucket goes up, but that is not enough to fully compensate for the loss of leverage.

To put it another way, the higher you go, the less you can lift. Designing for longer cylinders, allowing the fulcrum to be as far out as possible as long as possible, are more likely to lift a full bucket high enough to dump it on a pile or in a truck.

To put it another way, the higher you go, the less you can lift. Designing for longer cylinders, allowing the fulcrum to be as far out as possible as long as possible, are more likely to lift a full bucket high enough to dump it on a pile or in a truck.

I built my own loader for my B6100 and Torch knows what he is talking about. My bucket is too far forward and even with 400lbs on the 3pt, I have to pay attention as to how much is in the bucket. Especially with gravel.. I built my own block for the hydraulics. It's not that hard to do. If you have the capability to build a loader, you can make the block. I am planning on redesigning the arms this winter to shorten the distance between the buck and the wheels. I am too busy using it right now

H

H

do you have a few pictures of the hydraulics block? and where it goes. all my 6100 has is what looks like a banjo bolt on the top and bottom of the hydraulic pump going back to the 3pt hitch. i don't see where you would add the block. also a foe dimensions for the block would help me make one too.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

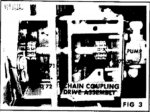

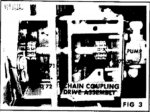

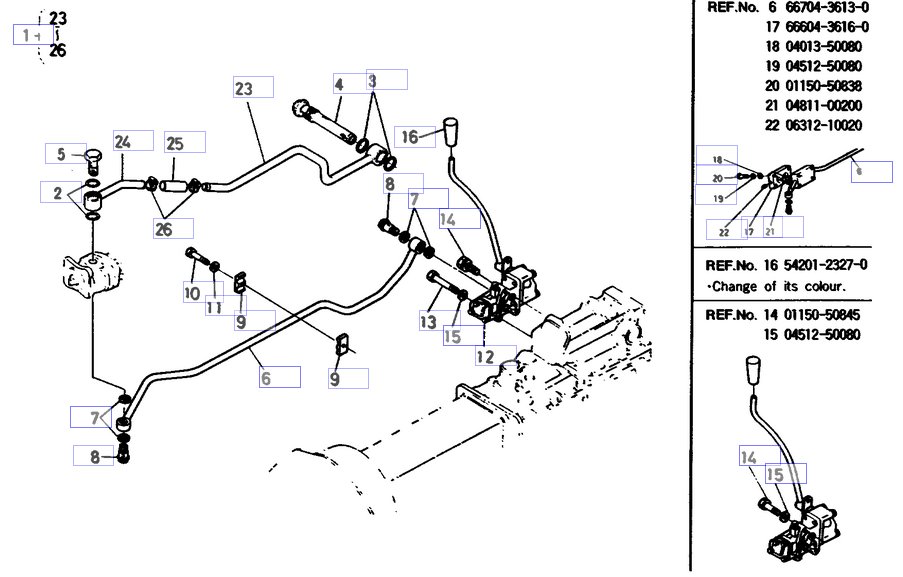

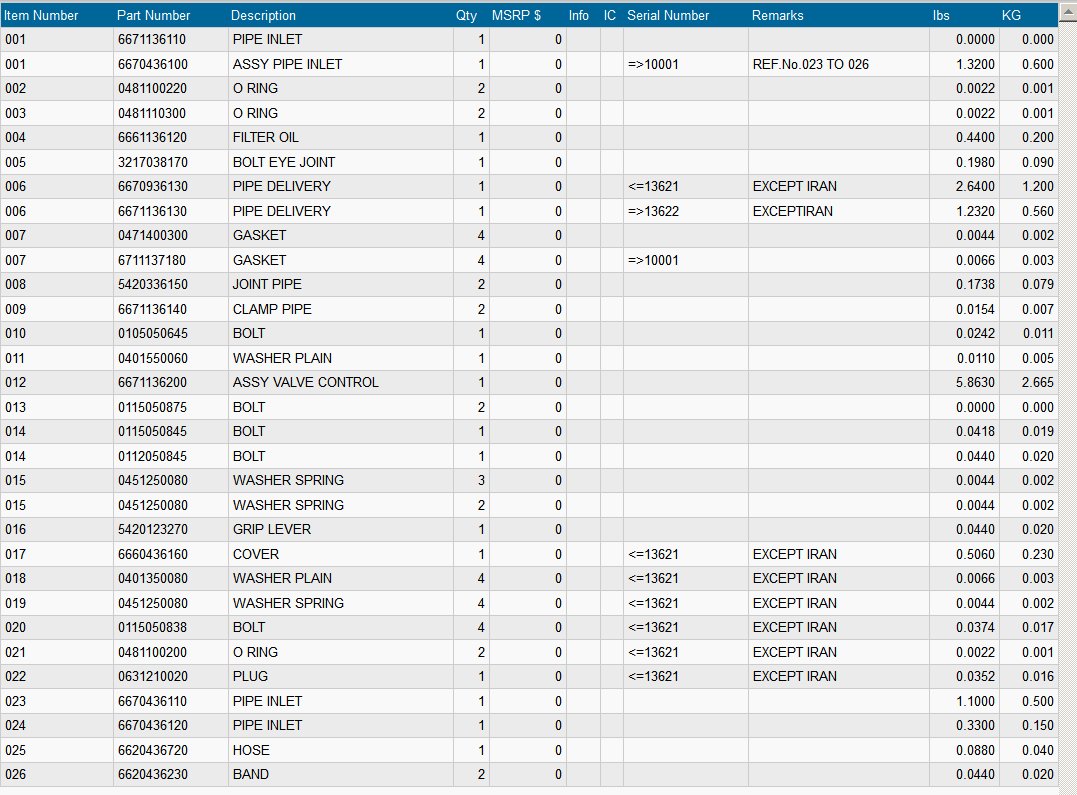

Models before serial number 13261 did not have a hydraulic block. Models after that serial number had it incorporated into the high pressure pipe, #6 in the images below:

If you have an earlier model, you will have to cut into the pipe to re-route the flow. Or find a later pipe, possibly a used one from a parts machine or wrecker.

If you have an earlier model, you will have to cut into the pipe to re-route the flow. Or find a later pipe, possibly a used one from a parts machine or wrecker.

That's what it is. Torch you are a life saver! If I cut the old pipe do I just flair it and add the block in? Do you happen to know the diameter of the pipe? I will know myself soon enough when I cut it to add a block but I would like to know I have the right size flair tool. I don't see bolt holes to bolt the block down with.

Last edited:

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Sorry, I don't know for sure off the top of my head and mine is the later style, so I can't even go out and measure it with confidence that the two are the same diameter. They could even be metric. You're on your own there kid. ;-)

As for connection type, you could use flare or compression on the existing tube, with an adapter to pipe or AN for the hose connection. If you plan to make the FEL removable, use a pair of tee fittings with a by-pass valve between them. Or use quick-disconnect fittings that will mate to each other. Disconnecting the FEL hoses without restoring the flow to the 3ph will quickly cause catastrophic failure the next time the engine is started.

As for connection type, you could use flare or compression on the existing tube, with an adapter to pipe or AN for the hose connection. If you plan to make the FEL removable, use a pair of tee fittings with a by-pass valve between them. Or use quick-disconnect fittings that will mate to each other. Disconnecting the FEL hoses without restoring the flow to the 3ph will quickly cause catastrophic failure the next time the engine is started.

Ok so I can use compression fittings, that make it a bit easier. I'm not very well versed in hydraulic circuits so forgive my ignorance. I need a bypass valve between the pressure and suction line where I T off for the FEL? And can I just use a T that goes to a quick attach?

I would talk to a hydraulic shop about that. I know compression fittings work up to 1200psi but not sure about higher. I have used hydraulic compression fittings to make/repair power steering lines on cars but tractor hyd might be a different animal. I wold not trust copper at all. Just my opinion

H

H

Ok so I have done some more research and have some more questions. When plumbing the hydraulics I add the diverter block that runs fluid from the pump through the loader controls and then to the 3pt hitch, when I plumb from the valve back to the 3pt hitch does that need to come from the open center for the power beyond? Also where is the best way to put the return into the tank?

barts

Active member

Equipment

4wd B5100 w/ FEL, box blade, JD110 TLB, WC68 chipper, log arch, brush mower.

Here's what I did to mount and drive a FEL (from a B7100 I think) on my B5100. https://www.orangetractortalks.com/...er-subframe-pics-or-description-wanted.17797/