Over the weekend I bought a 2000 B2400 HST that looked to be well cared for.... yesterday I hooked up my brushhog and tried to lift and nothing happens, I look down and I can see hydraulic fluid gushing out of the line. When I investigated I found a spliced piece of rubber hose on the metal hydraulic line. When I asked the previous owner how long that line had been spliced he acted like he didn't know about it. Replacing the line looks fairly straight forward - a 1" bolt at the position control valve, 2 smaller bolts at the hydraulic block type outlet and another nut at the flow priority valve. I can hardly get my wrench on the last nut because there's a another line beside it and in the way, am I OK to remove that line too? Sorry for the lengthy post.

Weekend buy

- Thread starter Bowhunterick

- Start date

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

I wonder if there is another way to fix that, other than the half/ars hose patch. Are the lines screwed in at the block or attached to the block as one unit?Over the weekend I bought a 2000 B2400 HST that looked to be well cared for.... yesterday I hooked up my brushhog and tried to lift and nothing happens, I look down and I can see hydraulic fluid gushing out of the line. When I investigated I found a spliced piece of rubber hose on the metal hydraulic line. When I asked the previous owner how long that line had been spliced he acted like he didn't know about it. Replacing the line looks fairly straight forward - a 1" bolt at the position control valve, 2 smaller bolts at the hydraulic block type outlet and another nut at the flow priority valve. I can hardly get my wrench on the last nut because there's a another line beside it and in the way, am I OK to remove that line too? Sorry for the lengthy post.

I didn't remove the block but it looks like it's a 1 piece line, the block has 2 hydraulic hoses connected to it, coming out of the front.

I think the hose is there for some flex in the system.

I'd take a box blade and cut the bad hose off. There should be a gap between the two steel lines. Get the new hose and take your knife to chamfer the inside edges and put a little oil on the (inside of) hose to make it slide on easier. Slide it on and pull it back the other direction and clamp.

I'd try this before removing the ends of the pipes.

Post some pictures so we get a visual of your situation.

I'd take a box blade and cut the bad hose off. There should be a gap between the two steel lines. Get the new hose and take your knife to chamfer the inside edges and put a little oil on the (inside of) hose to make it slide on easier. Slide it on and pull it back the other direction and clamp.

I'd try this before removing the ends of the pipes.

Post some pictures so we get a visual of your situation.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

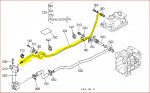

This is what your dealing with, nope no rubber hose in that line, it does have a rubber sleeve that fits over it for a clamp to ride on (#190).

Have your Serial# when you go to order a new line as there are 4 different #'s. also get 2 new crush washers #'s 160.

Have your Serial# when you go to order a new line as there are 4 different #'s. also get 2 new crush washers #'s 160.

Attachments

-

79 KB Views: 644

Central Joe

New member

Equipment

B7100 Grading Blade Disc Roto Tiller Scarifer Rake 48" Finish Mower

How about a compression fitting? I have repaired lines with them, but not sure about pres. you are working with. I would try it. joe

There are compression fittings for hydraulics. Areoquip or Swage-Lok are the common manufacturers.

Will also require a hydraulic hose made up. In this situation where there is little room for error, a new pipe would be money and time better spent.

Will also require a hydraulic hose made up. In this situation where there is little room for error, a new pipe would be money and time better spent.