That trailer looks to be in great shape for 40+ years old. Cool tractor too.Hauled the tractor to the dealer a days ago with my Dad’s 40+ year old flatbed he gave me in exchange for my getting it to DOT spec roadworthy, fixing brakes, etc. and his retained right to use it whenever I’m not using it, which I rarely do. Slide in ramps are a PITA to use but as rarely as I use it, not a big deal on a trailer I’m $750 into. Was very pleased with its performance.

No problem with the tractor. Had them install rear remotes.

Picture of your tractor on your trailer

- Thread starter miketrock

- Start date

Good deal.Not far. Only about 25 miles, mostly interstate so we did get it rolling at a pretty good clip.

Nice looking Tundra too.Hauled the tractor to the dealer a days ago with my Dad’s 40+ year old flatbed he gave me in exchange for my getting it to DOT spec roadworthy, fixing brakes, etc. and his retained right to use it whenever I’m not using it, which I rarely do. Slide in ramps are a PITA to use but as rarely as I use it, not a big deal on a trailer I’m $750 into. Was very pleased with its performance.

No problem with the tractor. Had them install rear remotes.

View attachment 62483 View attachment 62486 View attachment 62487 View attachment 62488 View attachment 62489

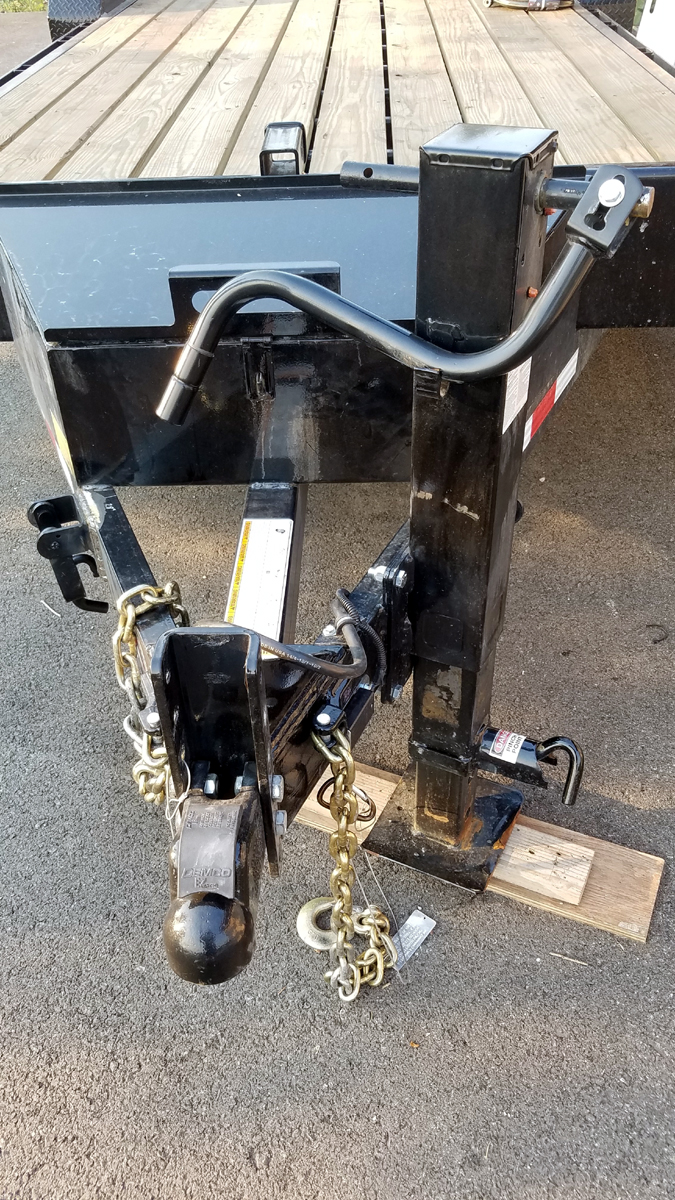

I tried to get the Curt weight distributing hitch installed today but it turned into a $hit show because the 7k lb jack is on the outside of the A frame and doesn't offer sufficient clearance for the trunnion bar. My PJ dump trailer has the jack inside the A frame so I'm going to move the jack to the inside and weld up both it and the hookup brackets to the frame.Post pics when completed and hooked up, would love to see and hear what difference it makes.

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

It’s definitely worth it if your rig is tongue heavy and you can’t fix it by repositioning the load. Looking at your prior posts, seems like that’s the situation you’re in.I tried to get the Curt weight distributing hitch installed today but it turned into a $hit show because the 7k lb jack is on the outside of the A frame and doesn't offer sufficient clearance for the trunnion bar. My PJ dump trailer has the jack inside the A frame so I'm going to move the jack to the inside and weld up both it and the hookup brackets to the frame.

Traditional camper trailers are set up to be tongue heavy and there’s no practical way to adjust the load, so the adjustment to tongue weight is done by changing the length of the chains between the spring bars and trailer frame. Shorten the chains to put more pressure on the spring bars = less tongue weight. Lengthen the chains to put less pressure on the spring bars = more tongue weight. I don’t have a weight distributing hitch on any of my trailers except our 9,000lb+ camper. I’m aware the physics of the weight distributing hitch is a bit more complex than described above. I’m also aware from a practical standpoint of setting up your rig, that’s what it boils down to. You can find a couple of truck scales and go all mechanical engineer on it, or get a tape measure after the front and rear of your truck as you set it up. Either way works.

For my current truck, and it’s predecessor, rear going down 1.5” to 2” and front going up about the same works well for the 5 ton flatbed when loaded heavy and the 4.5 ton camper even with one having weight distributing and the other not. Some people may tell you with a weight distributing hitch the truck should stay at the same height as unhitched. If you try that, just be careful first time out. I suspect you’ll get much better stability with a bit of weight on the back of the truck.

Past that, if you’re still not getting enough stability, then you might want to look at stiffening suspension with airbags, some sort of overloads, stiffer tires, etc. The big advantage of airbags is you can stiffen them when needed for load/stability or soften them for better ride when not needed. My Tundra has Sumo Springs because they work well and I can be cheap at times (airbags are swell but they ain’t cheap). Also chucked the squishy, squishy P rated tires for some 10 ply rated light truck tires. I run them at 32psi when not towing the bigger trailers. Air up to 45 rear, 40 front when towing the bigger trailers. Tires are rated for well over that.

Stopping or going with a 10K-lb or less trailer, never had a problem with that. Getting it rock solid stable took a little tweaking. I’d had that rock solid stability with my previous camper rig, so I couldn’t leave it alone until I had that back.

Good luck, and whatever you do, just make sure you don’t take too much weight off the rear of the truck or get the front of the truck too light. Taking measurements before hooking up the trailer and after should keep your rig in a safe enough range to road test for fine tuning.

key here is Taking Measurements! super important.. every time i switch trucks, i spend some time hooking up my 8000lb camper. All on flat ground. Measure front and rear (i use the distance at the middle of the fender above the tire). I hook up with no distribution bars to see what the max rear sag and front lift is going to be. Then adjust from there. After doing it with 4 different trucks now, it doesnt take as long. but i lift the weight, toss it on the 3rd chain link and use that as my base measurement. On the 1500 rams i was on the 5th link, on my old silverado i was on the 4th, and my last truck an F150 that the previous owner installed an additional leaf on i was on the 2nd link. Once my 21 silverado shows up, i will measure and then set it to the 4th link to measure and go from there. I also do it with full propane tanks.

It’s definitely worth it if your rig is tongue heavy and you can’t fix it by repositioning the load. Looking at your prior posts, seems like that’s the situation you’re in.

Traditional camper trailers are set up to be tongue heavy and there’s no practical way to adjust the load, so the adjustment to tongue weight is done by changing the length of the chains between the spring bars and trailer frame. Shorten the chains to put more pressure on the spring bars = less tongue weight. Lengthen the chains to put less pressure on the spring bars = more tongue weight. I don’t have a weight distributing hitch on any of my trailers except our 9,000lb+ camper. I’m aware the physics of the weight distributing hitch is a bit more complex than described above. I’m also aware from a practical standpoint of setting up your rig, that’s what it boils down to. You can find a couple of truck scales and go all mechanical engineer on it, or get a tape measure after the front and rear of your truck as you set it up. Either way works.

For my current truck, and it’s predecessor, rear going down 1.5” to 2” and front going up about the same works well for the 5 ton flatbed when loaded heavy and the 4.5 ton camper even with one having weight distributing and the other not. Some people may tell you with a weight distributing hitch the truck should stay at the same height as unhitched. If you try that, just be careful first time out. I suspect you’ll get much better stability with a bit of weight on the back of the truck.

Past that, if you’re still not getting enough stability, then you might want to look at stiffening suspension with airbags, some sort of overloads, stiffer tires, etc. The big advantage of airbags is you can stiffen them when needed for load/stability or soften them for better ride when not needed. My Tundra has Sumo Springs because they work well and I can be cheap at times (airbags are swell but they ain’t cheap). Also chucked the squishy, squishy P rated tires for some 10 ply rated light truck tires. I run them at 32psi when not towing the bigger trailers. Air up to 45 rear, 40 front when towing the bigger trailers. Tires are rated for well over that.

Stopping or going with a 10K-lb or less trailer, never had a problem with that. Getting it rock solid stable took a little tweaking. I’d had that rock solid stability with my previous camper rig, so I couldn’t leave it alone until I had that back.

Good luck, and whatever you do, just make sure you don’t take too much weight off the rear of the truck or get the front of the truck too light. Taking measurements before hooking up the trailer and after should keep your rig in a safe enough range to road test for fine tuning.

@NCL4701, thanks for the excellent information. I'd love to be at the stage where I can think about the issues you mention but I'm still stuck on moving the 7k lb jack. I figured out that I need to "cock" the jack inside the A-frame so that the handle is free to rotate. If it's positioned orthogonally with the handle out to one side or out to the front it'll hit either the toolbox or the coupler mounting bracket. That means I need to build out some plate on the center tube to give me the angle and a mounting surface for the jack. I'll get there but it's been a pain thus far.

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

Hope you figure out something that isn’t too convoluted. I have a flip jack on the 5 ton; kind of a crappy pic because that’s not what I was trying to photo but it has a beam welded in the center of the A that runs straight from the hitch to the front of the deck. It’s just long enough to allow mounting of the rotating flip jack. You may notice it also has a plate right behind the hitch with a big round hole surrounded by little holes. That’s for mounting a fixed vertical jack like I have on the camper (other pic). Yeah it hangs down a bit but not as far as the weight distributing spring bars.@NCL4701, thanks for the excellent information. I'd love to be at the stage where I can think about the issues you mention but I'm still stuck on moving the 7k lb jack. I figured out that I need to "cock" the jack inside the A-frame so that the handle is free to rotate. If it's positioned orthogonally with the handle out to one side or out to the front it'll hit either the toolbox or the coupler mounting bracket. That means I need to build out some plate on the center tube to give me the angle and a mounting surface for the jack. I'll get there but it's been a pain thus far.

You can see that the jack is in the way. A hook up bracket needs to be added to the jack side of the frame opposite to the one I welded on the left side.

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

The drop foot and pin setup looks nice if you can keep it positioned and oriented such that it remains readily accessible. And wow, that’s a big jack for a bumper pull trailer.You can see that the jack is in the way. A hook up bracket needs to be added to the jack side of the frame opposite to the one I welded on the left side.

View attachment 63133

Kind of a Chinese puzzle you got there. Longer I look at it the more of a PITA it looks like to move it. Sounds like you have it figured out, though with moving the bracket.

I think I've got it figured out. I'm going to notch the center tube (see cross-hatched region below), separate the jack from the mounting plate and weld it into the notch. I'll probably add a gusset at the rear of the jack and I like that the seam is on the side of the notch. The handle will easily clear the tool box and I'll have access to the foot and pin. This should work well.The drop foot and pin setup looks nice if you can keep it positioned and oriented such that it remains readily accessible. And wow, that’s a big jack for a bumper pull trailer.

Kind of a Chinese puzzle you got there. Longer I look at it the more of a PITA it looks like to move it. Sounds like you have it figured out, though with moving the bracket.

redfalcon302

New member

Equipment

L3800, LA524 SSQA loader, RCF2060 rotary cutter, EA Land Shark Plane, Box Blade

Here's my L3800, loader, and 5.5' box scraper on my 19' Kaufman trailer behind my 2000 Tahoe. Pulls pretty well, but I haven't had it on the interstate. Don't really intend to as I only move it between Knoxville and Oliver Springs (about 30 miles or so) once in a while.

For any of you using a weight distributing hitch on your truck and trailer, do you tend to use it for one configuration and remember the setup or do you have to change it for different loads? For example, if you're towing the tractor with and without implements attached I would assume you have to change the setup unless you're able to position equipment to achieve the same or similar tongue weight.

Getting ready to tow the tractorThanks for the help ended up getting a 20’ gravity tilt deck haven’t bought the grapple yet ... still deciding on what type View attachment 56458

wrong tow vehicle or trailer or both?? Getting ready to tow tractor first time and was told by a hauler the Sierra 1500 (‘14 w/ 6.2L eng, tow pkg, 3.73 ratio) wasn’t up to the job! By my calculations the tractor plus implements is 4500#, trailer is 3300# or 7800# gross weight. Truck says it’s capable of 9000# gross tow weight (w weight distributing hitch) and 15k combined … guy says it’ll run like a dog up the hills and won’t be in the sweet spot of the torque curve w the 3.73. Is this all true and I should be looking for a lighter aluminum trailer (I don’t want to be buying a new truck in this market) ? Thinking of loading it up and testing, if I can get the tongue weight right.Thanks for the help ended up getting a 20’ gravity tilt deck haven’t bought the grapple yet ... still deciding on what type View attachment 56458

I only use my distribution hitch on my camper it’s about 8000lbs but I can’t manipulate where the weight is very easily. My 18’ flat deck trailer is 2000lbs empty, when I toss the tractor and implements on it. I just distribute the weight on the trailer. Pretty much watch the truck and let the back end drop about 2” then I hit the park brake on the tractor and strap/chain things down.For any of you using a weight distributing hitch on your truck and trailer, do you tend to use it for one configuration and remember the setup or do you have to change it for different loads? For example, if you're towing the tractor with and without implements attached I would assume you have to change the setup unless you're able to position equipment to achieve the same or similar tongue weight.