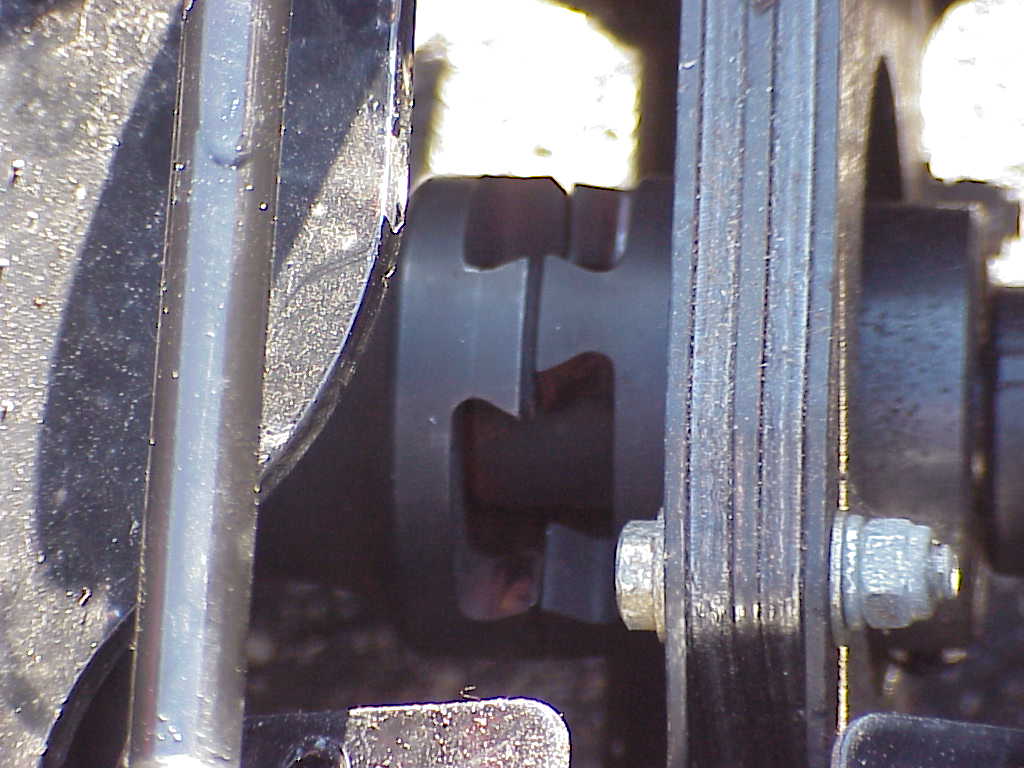

I have been giving this issue of the K Connect connection parts wearing out prematurely some thought over the past few days. I developed a hypothesis as to the cause and effect of raising the snowblower too high when it is being powered by the PTO. Today was a warm day, so I took the time to remove the 4 bolts that hold the safety cover off of the K Connect and photograph how the coupling works and what goes wrong when you lift it too high. In this first picture, you can see the way that the connector looks when it is randomly engaged by pulling the K Connect lever to the engaged position. Note how the two tabs of the coupling are touching.

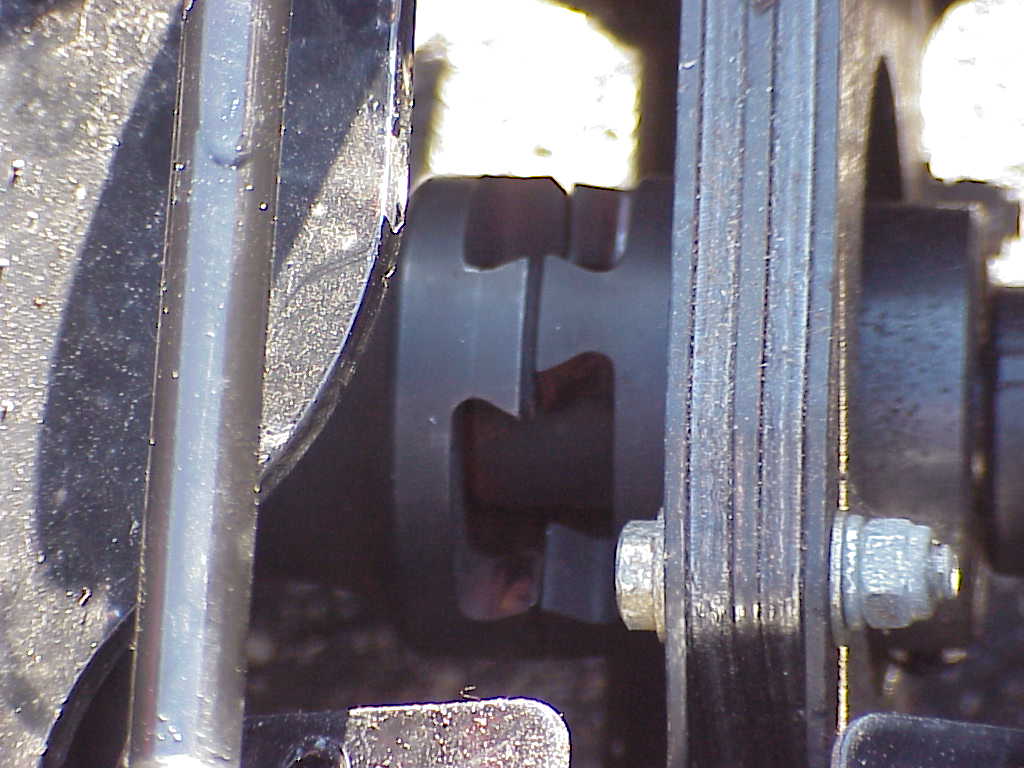

In picture #2, I engaged the coupling by starting the tractor and moving the PTO lever into the working position with the snowblower setting on the ground. You will note that the coupling isn't fully engaged, and since my locking pins for the couplings are both in the factory setting position, I believe that Kubota never intended them to fully engage tightly. I believe that might be a mistake on their part, but I will leave that to the engineers to sort out.

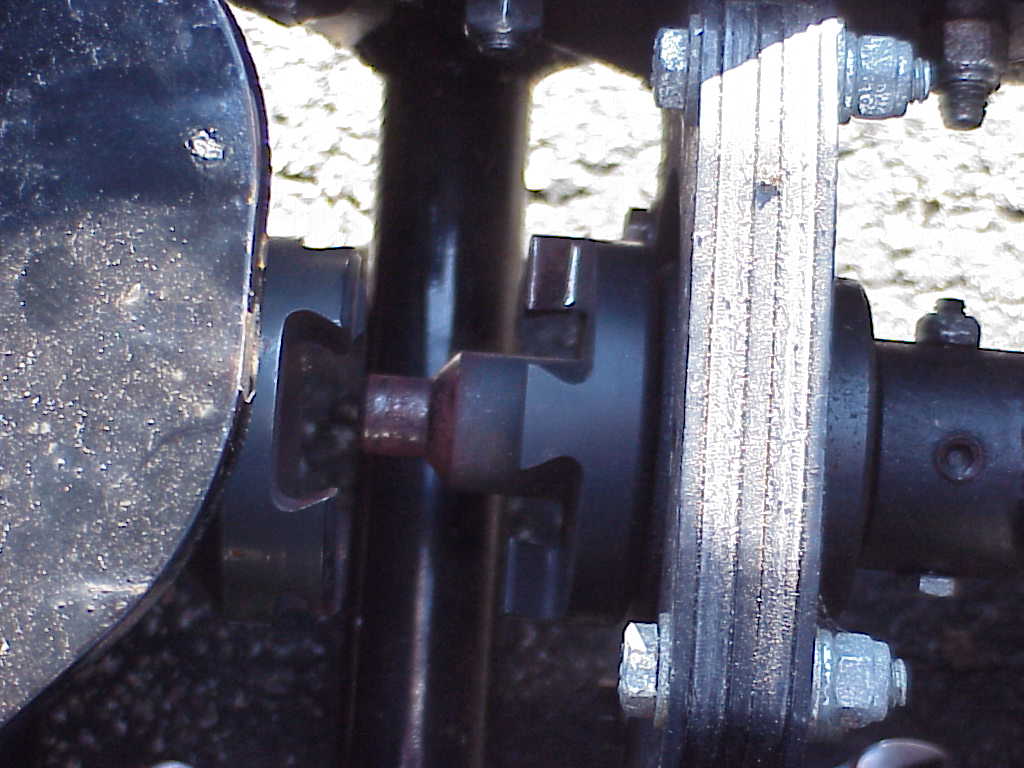

In picture #3 I disengaged the coupling to see what it looked like as I moved the bar toward the engaged position. The design of the K Connect is that the tractor side of the connection floats and only when you engage does it self-center itself.

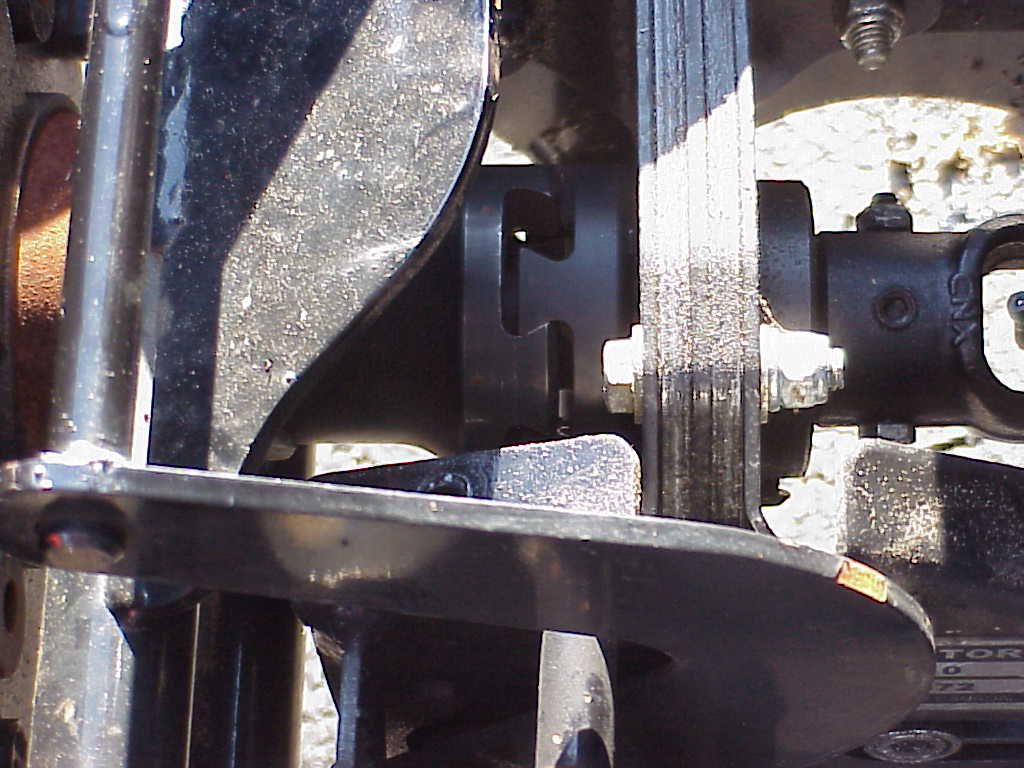

In the last picture, you can see how the coupling separates when the snowblower is in its full-up position. It doesn't look like much, but I believe that it is enough to cause the premature wears that many people are seeing.

In conclusion, I believe that you should limit the lifting of the snowblower to just an inch or so to keep it from dragging when you go in reverse. There is no reasonable reason to raise the snowblower fully, and I believe that if you don't completely raise the snowblower fully, you will lessen the wear on the K Connect coupling. As I said in the beginning, this is just a supposition of my thoughts, and I encourage you to remove the 4 bolts from the cover and perform the same testing that I have done. All pictures that I have taken were with the tractor not running since if it were running, you wouldn't be able to see the differences unless you have a strobe light to "stop the action".

In picture #2, I engaged the coupling by starting the tractor and moving the PTO lever into the working position with the snowblower setting on the ground. You will note that the coupling isn't fully engaged, and since my locking pins for the couplings are both in the factory setting position, I believe that Kubota never intended them to fully engage tightly. I believe that might be a mistake on their part, but I will leave that to the engineers to sort out.

In picture #3 I disengaged the coupling to see what it looked like as I moved the bar toward the engaged position. The design of the K Connect is that the tractor side of the connection floats and only when you engage does it self-center itself.

In the last picture, you can see how the coupling separates when the snowblower is in its full-up position. It doesn't look like much, but I believe that it is enough to cause the premature wears that many people are seeing.

In conclusion, I believe that you should limit the lifting of the snowblower to just an inch or so to keep it from dragging when you go in reverse. There is no reasonable reason to raise the snowblower fully, and I believe that if you don't completely raise the snowblower fully, you will lessen the wear on the K Connect coupling. As I said in the beginning, this is just a supposition of my thoughts, and I encourage you to remove the 4 bolts from the cover and perform the same testing that I have done. All pictures that I have taken were with the tractor not running since if it were running, you wouldn't be able to see the differences unless you have a strobe light to "stop the action".

Last edited: