I went to Tae Kwon Do Tournament in Toronto all day yesterday

As OB1 said already, I never could believe Kubota engineer wouldn't design or build those tractor that grinding gears~!!!

Like anything else, it breaks. then we have to fix, Don't we? so asking questions here and getting a lot of good answers from everyone. including a tons of Ob1's. I really love Ob1. indeed everyone here. I mean it. althogh I'm not a GAY or mangled Joe yet~

**********************************************************

Lets review your steps above now that we have definitely established that you only have a single disc clutch with one single adjustment.

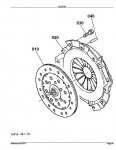

1. Clutch is out of adjustment and still making light pressure contact ( slipping) with flywheel.

2. You have proven to yourself this is happening by externally depressing the clutch petal with a 2x4 while creating resistance on the PTO shaft overriding the flywheel kinetic energy.

3. With the PTO engaged the mechanical advantage has shifted in the reverse ( resistance ) to flywheel inertia balancing the movement to neutral thus no drivetrain grinding is experienced.

Final thoughts and recommendation Joe.

Kubota didn't design this system to ACT as it currently is... I think everybody reading this post agrees on that statement... and further I recommend a simple attempt to adjust the

clutch FREE PETAL TRAVEL is in order before building a mechanical shaft stopping device to prevent a mangled Joe

. If your clutch is properly adjusted and you declutch placing the transmission in neutral and after five seconds there should be no gear movement happening anywhere in the output drivetrain to PTO engaged or disengaged. If you still have movement in the neutral position with the shifter tower in this position, (Hint: to be sure you are in neutral rock the shifter tower handle knob back and forth side ways freely) your transmission is still receiving kinetic energy from the flywheel ( prime mover ) because the clutch is maladjusted (Slipping against the flywheel) or the transmission shifter yoke is bent and hanging in gear in the nuetral position causing the output (PTO ) shaft to turn when you have it engaged.

**********************************************************

Okay, I did clutch adjustment before as I repied to Dusty too.

There was 2" clutch play. so I changed to 1". and there are bolt and nuts for Clutch rod travel adjusting bolt there too and Shop manual says 8.9 mm to keep. and it was 8.9mm already. but I gave all the way open to try to stop the grinding but it still did. so I put it back to 9 mm.

Another word, clutch adjustment is all done by Work Shop Manual.

and only thing I couldn't do is inside of inspection window to check in there.

For that, I have to wait for my neighbor mechanic to look at it for me.

Frankly, I don't know what to look in there.

Even some said, there should be a clutch travel bearing (?) to grease but I never could find one~

I'm the one who ask for

"Leather belt" but I guess it is bad idea~~~

What should I do now~???

Please, save me from DARK SIDE~!

Joe.