It seems like every time see a finish mower post it's about failed spindles but I never realized that it is a serious design flaw in many of the spindles.

If you search for the spindles online they are everywhere and cheap (27.00 to 99.00) so I started looking into the design of the 1500.00 to 2000.00 finish mowers and I was shocked at what I found.

The spindles are made with ball bearings, ball bearings are not designed to have side loads and that seems to be why they fail.

If you look at the spindles in a Woods RD6000 they use tapered bearings like front wheel bearings in a lot of cars and trucks and that's why their replacement spindles cost 236.00.

I'm planning to try and modify the ball bearing spindles to accept the tapered bearings.

Has anyone else found a different solution?

If you search for the spindles online they are everywhere and cheap (27.00 to 99.00) so I started looking into the design of the 1500.00 to 2000.00 finish mowers and I was shocked at what I found.

The spindles are made with ball bearings, ball bearings are not designed to have side loads and that seems to be why they fail.

If you look at the spindles in a Woods RD6000 they use tapered bearings like front wheel bearings in a lot of cars and trucks and that's why their replacement spindles cost 236.00.

I'm planning to try and modify the ball bearing spindles to accept the tapered bearings.

Has anyone else found a different solution?

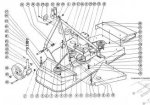

Attachments

-

20.8 KB Views: 370

-

10.6 KB Views: 388

-

11.7 KB Views: 386