Hi, I recently acquired a B7100 HST-D new style. I believe 1994. 406 Hrs. My plans are to use the front mounted snow blower this winter.

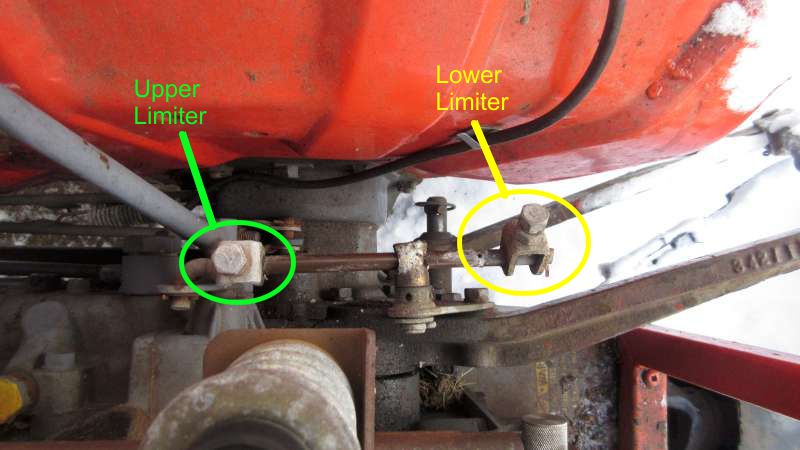

The issue is, the 3 point lift only works from the all the way down position up to 3". Anything after that It sounds like its maxed out - like the hydraulic pump is whining on the stops.

I did borrow the tractor last year, same set up, and it worked flawlessly. The person I got it from said he doesn't recall having any issues but didn't use it much this summer.

Things I have done attempting to remedy problem: Changed hydraulic fluid and filter with UDT fluid, removed both large screws and cleaned screens/filters (very little to no debris) , made sure the knob under front of seat is in correct direction, and tried with low to full engine power. All of this have made no change. I don't think there is a pressure loss as the lift moves quickly for those 2-3 inches until it stops.

My next steps are to removed the control valve or front pump and check for o-ring damage. Any other suggestions are appreciated.

The issue is, the 3 point lift only works from the all the way down position up to 3". Anything after that It sounds like its maxed out - like the hydraulic pump is whining on the stops.

I did borrow the tractor last year, same set up, and it worked flawlessly. The person I got it from said he doesn't recall having any issues but didn't use it much this summer.

Things I have done attempting to remedy problem: Changed hydraulic fluid and filter with UDT fluid, removed both large screws and cleaned screens/filters (very little to no debris) , made sure the knob under front of seat is in correct direction, and tried with low to full engine power. All of this have made no change. I don't think there is a pressure loss as the lift moves quickly for those 2-3 inches until it stops.

My next steps are to removed the control valve or front pump and check for o-ring damage. Any other suggestions are appreciated.