Got that instant patina!Some of you may realize how fun it might be to weld on a rusty pipe this thin. Well, i did it. I flap disced it down and it quickly rusted to blend right in with the existing material.

B6100 w/ Loader+Backhoe

- Thread starter Vigo

- Start date

Another thing I had to fix was 'everything about the throttle linkage'.

Multiple issues:

First thing was rejoin the pedal shaft to the arm it rotates. I took the lazy way out here and didn't even inspect for a sheared roll pin or whatever the actual reason was that these two parts spun loose. I just put both sides in the correct position and buzzed it in place while laying on the ground next to the tractor. Also seen is washer and hairpin i put in the brake/clutch/diff lock rods. I tried to replace nearly all cotter pins with hairpins on the rod linkages on the tractor. As a mechanic i spend innumerable seconds walking back and forth between toolboxes and workpiece getting tools and i like that with a hairpin you can usually get it out and back in with no tools if you have to. Some places need cotters but these locations are well protected and i dont expect the hairpins to ever get pulled off accidentally.

Also, if you didn't know these tractors have grease fittings on the pedal shafts, you should go grease yours!

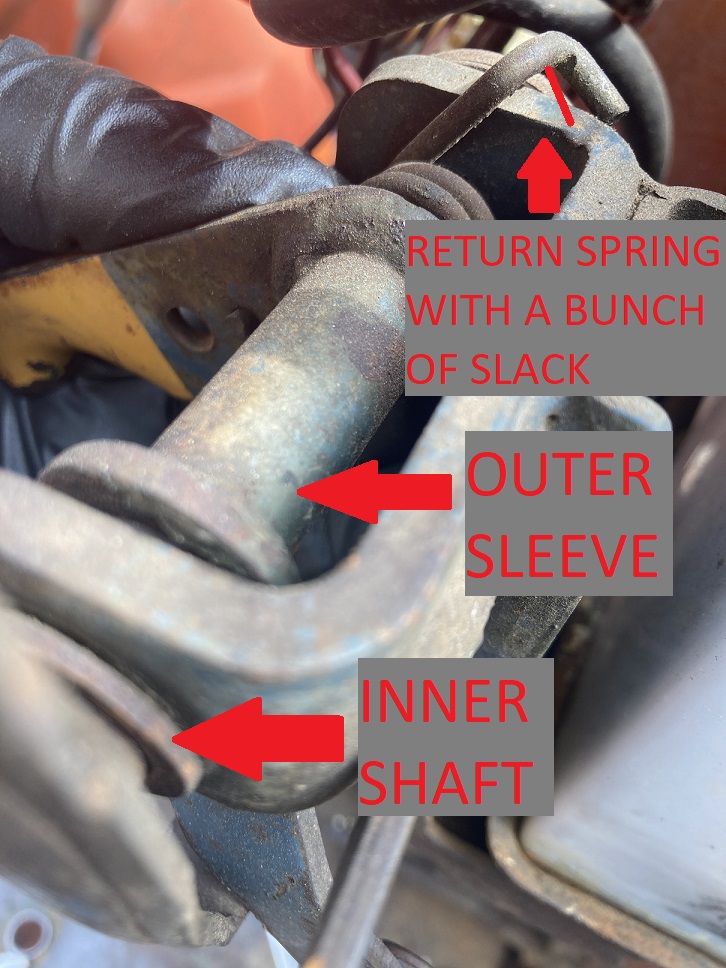

So i dont remember how but i pressed or hammered this apart and wire wheeled the inner and outer surfaces clean of rust.

I really love these little 1/4" hex 'pipe cleaner' style wire wheels that i can stick in my cordless impact and zing up to ludicrous speed. I used them extensively on this tractor since i fixed just about every damn thing that pivots, including the hood.

Before reassembling the bracket i also drilled a new hole for the return spring to pin into to take all the slack back out of it. Of course, since i am insufficiently (apparently..) medicated for ADHD i usually forget what i was doing before i finish doing it, so after drilling the new hole i convinced myself i had everything backwards and drilled another hole on the other side. Then i took it to the tractor and found out i had it right the first time.

Next i fixed the bent throttle rod. I removed the adjustable bracket from the threaded section at the end of the rod, which was bent right outside where the locknut had been on the shaft. Unfortunately i dont have a pic of the bend before repair, so this might be a bit abstract.. Its tricky to push real hard on a small threaded section of something without damaging the threads. In order to prevent damaging the threads while straightening the rod, i trapped a box end wrench between two flanged nuts. I then held the unthreaded section of the rod, and unbent the threaded section by prying through the open end of the wrench. I usually do this trick the opposite way by slipping the open end over a pipe/rod and then prying in the boxed end. In this process, i was pushing on the threaded rod through the nuts themselves which fit perfectly to the threads and avoided putting any damage on this small part.

Next was to get the seized cotter pin out of the small bracket that goes onto that threaded rod.

I trimmed it close to flush, then ground it down to truly flush because i knew it would be very hard for a tiny punch (or worst case, drill bit) to 'find' and enter the original hole if it was balanced on top of an oddly shaped lump sitting proud of the hole. This too will quickly surface rust until it blends in.

Next i found a set of vise grips to serve as a tiny vise and prevent the part from rotating when i hit it.

Flawless victory. You can see that as soon as i touched the part with my greasy gloves the fresh grind marks practically disappeared.

Continued..

Multiple issues:

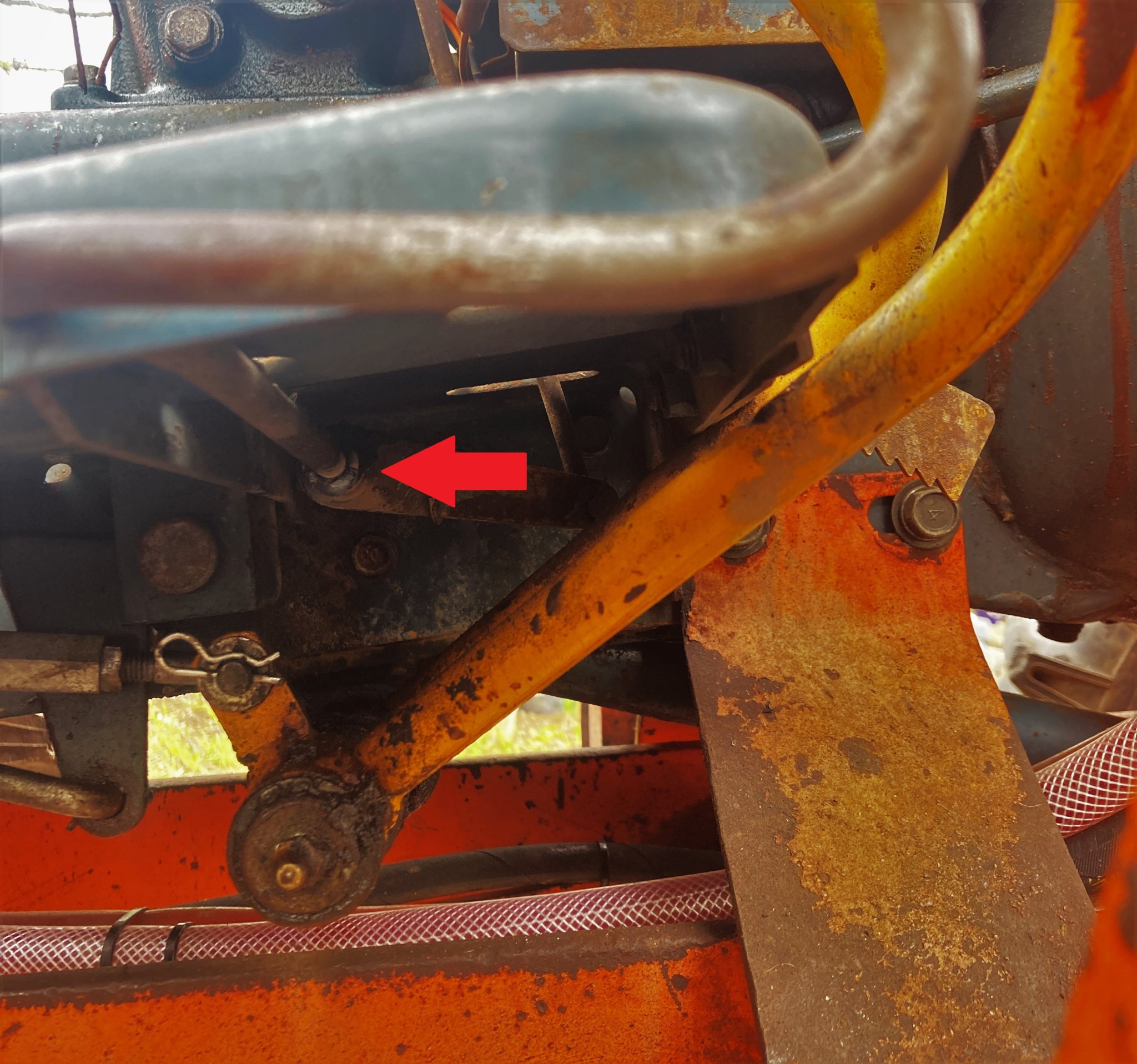

- The throttle pedal shaft was broke loose from the arm it rotates and spun freely inside, thus the pics of the throttle pedal hanging loose way before the floorboard.

- The inner and outer layers of the throttle linkage under the dash were seized together, meaning that if the pedal were hooked up it would also move the hand lever, etc. The two are supposed to move freely of each other.

- The pedal return spring on said bracket was fatigued enough that it had a bunch of slack and no preload at all.

- The rod connecting the throttle linkage under the dash to the top of the injection pump was bent, and the small cotter pin holding the rod to the throttle arm under the dash was bent over, seized in place, and there was no washer, so the rod would frequently fall out of the arm.

First thing was rejoin the pedal shaft to the arm it rotates. I took the lazy way out here and didn't even inspect for a sheared roll pin or whatever the actual reason was that these two parts spun loose. I just put both sides in the correct position and buzzed it in place while laying on the ground next to the tractor. Also seen is washer and hairpin i put in the brake/clutch/diff lock rods. I tried to replace nearly all cotter pins with hairpins on the rod linkages on the tractor. As a mechanic i spend innumerable seconds walking back and forth between toolboxes and workpiece getting tools and i like that with a hairpin you can usually get it out and back in with no tools if you have to. Some places need cotters but these locations are well protected and i dont expect the hairpins to ever get pulled off accidentally.

Also, if you didn't know these tractors have grease fittings on the pedal shafts, you should go grease yours!

So i dont remember how but i pressed or hammered this apart and wire wheeled the inner and outer surfaces clean of rust.

I really love these little 1/4" hex 'pipe cleaner' style wire wheels that i can stick in my cordless impact and zing up to ludicrous speed. I used them extensively on this tractor since i fixed just about every damn thing that pivots, including the hood.

Before reassembling the bracket i also drilled a new hole for the return spring to pin into to take all the slack back out of it. Of course, since i am insufficiently (apparently..) medicated for ADHD i usually forget what i was doing before i finish doing it, so after drilling the new hole i convinced myself i had everything backwards and drilled another hole on the other side. Then i took it to the tractor and found out i had it right the first time.

Next i fixed the bent throttle rod. I removed the adjustable bracket from the threaded section at the end of the rod, which was bent right outside where the locknut had been on the shaft. Unfortunately i dont have a pic of the bend before repair, so this might be a bit abstract.. Its tricky to push real hard on a small threaded section of something without damaging the threads. In order to prevent damaging the threads while straightening the rod, i trapped a box end wrench between two flanged nuts. I then held the unthreaded section of the rod, and unbent the threaded section by prying through the open end of the wrench. I usually do this trick the opposite way by slipping the open end over a pipe/rod and then prying in the boxed end. In this process, i was pushing on the threaded rod through the nuts themselves which fit perfectly to the threads and avoided putting any damage on this small part.

Next was to get the seized cotter pin out of the small bracket that goes onto that threaded rod.

I trimmed it close to flush, then ground it down to truly flush because i knew it would be very hard for a tiny punch (or worst case, drill bit) to 'find' and enter the original hole if it was balanced on top of an oddly shaped lump sitting proud of the hole. This too will quickly surface rust until it blends in.

Next i found a set of vise grips to serve as a tiny vise and prevent the part from rotating when i hit it.

Flawless victory. You can see that as soon as i touched the part with my greasy gloves the fresh grind marks practically disappeared.

Continued..

Last edited:

New hardware and back to the tractor. I used those same two plated flange nuts instead of the rusty plain nuts that came off, and adjusted the linkage.

The rod i had to straighten was bent at the thread and also more gradually along its length because it was misadjusted. Whenever the lever on the injection pump end maxes out, you need the lever at the dashboard end to max or nearly max out as well. If the injection pump end won't go any further but the dashboard end you are pushing with your hand or jamming with your foot can go further, then guess what? You bend the rod! Heck, you may even break the arm loose on the pedal shaft, lay over the cotter pin and push the bracket right past it and pop the linkage apart in the process. It probably took 'multiple attempts' to get it to this point.

On the other hand, many tractors have a coil spring 'overtravel' mechanism on the rod linkage so that if you max out the engine end of things you start compressing a spring instead of bending and breaking things. If this tractor had that it probably only would have needed repair from age/sitting (seized/rusty) but wouldn't have as much or any damage from hamfisted (&footed) operators.

So, it was adjusted so as not to be able to force it past max throttle and put the rod in serious compression and bending. Anyway, now nothing is seized, its adjusted properly, the foot pedal works, and the return spring properly returns the pedal.

So by far the biggest part of this entire project was the refurbishment of the B670 backhoe.

Here is how i received it.

It was not mounted to the tractor, and one of the main mounting plates was missing anyway, so i was not able to mount it for a bit while we waited for the seller to locate the plate. Luckily he did eventually come through with it. I think i read somewhere that the B670 weighs about 750 lbs, but luckily my B8200 which only has a stock 'lift to full height' capacity of 700 lbs, was still able to unload it even hanging out beyond the bucket on a pair of forks.

When i initially mounted it up, i used it as-is a bit to find out what it needed. Basically, it was just sloppy and loose all over, had some bent parts, leaked a bit, bucket was just about rusted through, and control linkages were so worn out that getting any bucket curl at all was tricky.

I think i used it to trench the last 50ft or so of the ~1000ft water line to my house. The pipe sticking out at left is coming out of the brand new septic tank that was just put in by a backhoe with a FOURTY-EIGHT inch bucket. Same size as the front loader bucket on this thing. Those rocks in the background came out during the septic install and this little tractor, at least stock, could not have lifted most of them with the FEL.I changed that later, but anyway..

Those rocks in the background came out during the septic install and this little tractor, at least stock, could not have lifted most of them with the FEL.I changed that later, but anyway..

Septic work. The oddly placed galvanized tank was there because i had been using it as a giant reflector to light up my work area with the headlights of that white car while i worked on septic plumbing in the dark the night before.

I used it a bit along my creek as i built a couple of retaining walls around a 24" culvert pipe for the creek crossing.

I guess i'd say i never did get a proper accounting in my head of how much work the backhoe needed because i started off keeping it mounted and assembled and just doing things here and there only taking apart what i felt i needed to. That turned out to the long way around because eventually i blew it apart all the way down to the subframe, took the subframe off the tractor, and repaired and reinstalled it one piece at a time. I probably should have done that from the beginning!

Here is how i received it.

It was not mounted to the tractor, and one of the main mounting plates was missing anyway, so i was not able to mount it for a bit while we waited for the seller to locate the plate. Luckily he did eventually come through with it. I think i read somewhere that the B670 weighs about 750 lbs, but luckily my B8200 which only has a stock 'lift to full height' capacity of 700 lbs, was still able to unload it even hanging out beyond the bucket on a pair of forks.

When i initially mounted it up, i used it as-is a bit to find out what it needed. Basically, it was just sloppy and loose all over, had some bent parts, leaked a bit, bucket was just about rusted through, and control linkages were so worn out that getting any bucket curl at all was tricky.

I think i used it to trench the last 50ft or so of the ~1000ft water line to my house. The pipe sticking out at left is coming out of the brand new septic tank that was just put in by a backhoe with a FOURTY-EIGHT inch bucket. Same size as the front loader bucket on this thing.

Septic work. The oddly placed galvanized tank was there because i had been using it as a giant reflector to light up my work area with the headlights of that white car while i worked on septic plumbing in the dark the night before.

I used it a bit along my creek as i built a couple of retaining walls around a 24" culvert pipe for the creek crossing.

I guess i'd say i never did get a proper accounting in my head of how much work the backhoe needed because i started off keeping it mounted and assembled and just doing things here and there only taking apart what i felt i needed to. That turned out to the long way around because eventually i blew it apart all the way down to the subframe, took the subframe off the tractor, and repaired and reinstalled it one piece at a time. I probably should have done that from the beginning!

I saw a bl4590 for sale down near Rockport some months ago and contemplated buying it. Looked very rough and was not anywhere near the original host tractor.So by far the biggest part of this entire project was the refurbishment of the B670 backhoe.

Here is how i received it.

View attachment 105280

View attachment 105281

It was not mounted to the tractor, and one of the main mounting plates was missing anyway, so i was not able to mount it for a bit while we waited for the seller to locate the plate. Luckily he did eventually come through with it. I think i read somewhere that the B670 weighs about 750 lbs, but luckily my B8200 which only has a stock 'lift to full height' capacity of 700 lbs, was still able to unload it even hanging out beyond the bucket on a pair of forks.

When i initially mounted it up, i used it as-is a bit to find out what it needed. Basically, it was just sloppy and loose all over, had some bent parts, leaked a bit, bucket was just about rusted through, and control linkages were so worn out that getting any bucket curl at all was tricky.

View attachment 105282

I think i used it to trench the last 50ft or so of the ~1000ft water line to my house. The pipe sticking out at left is coming out of the brand new septic tank that was just put in by a backhoe with a FOURTY-EIGHT inch bucket. Same size as the front loader bucket on this thing.Those rocks in the background came out during the septic install and this little tractor, at least stock, could not have lifted most of them with the FEL.I changed that later, but anyway..

View attachment 105283

Septic work. The oddly placed galvanized tank was there because i had been using it as a giant reflector to light up my work area with the headlights of that white car while i worked on septic plumbing in the dark the night before.

View attachment 105284

I used it a bit along my creek as i built a couple of retaining walls around a 24" culvert pipe for the creek crossing.

I guess i'd say i never did get a proper accounting in my head of how much work the backhoe needed because i started off keeping it mounted and assembled and just doing things here and there only taking apart what i felt i needed to. That turned out to the long way around because eventually i blew it apart all the way down to the subframe, took the subframe off the tractor, and repaired and reinstalled it one piece at a time. I probably should have done that from the beginning!

So the first repair I did upon mounting the backhoe was to replace all the hoses and a fair number of fittings.

Here's what one tiny backhoe worth of hoses from Surplus Center looks like.

Some fittings were replaced due to thread damage.

Of course those tended to be the ones that were the hardest to see/access (why did the last guy screw them up in the first place? duh) so i had to find that out the hard way and straighten out a few hose end threads with a thread file. Which, i don't have an NPT thread file and all these hoses were 1/4 NPT, so i just figured out which metric thread was close enough to make up for with finesse. NPT is a bit weird because when you first start threading youre engaging the smallest male thread to the largest female thread so it seems easier than usual to screw up the first thread, but if you're threading by hand you can still tell when its not right. Nobody ever laid any threads over with the sheer power of the finger wrench, so the problem comes when you don't notice that it doesn't feel right, and start putting tools to it anyway! Which i apparently did at least once.

I also installed a bunch of NPT swivel fittings in locations where the hoses had been screwed directly into the cylinders, or into an elbow on the cylinder. For ~$3/each at surplus center these tiny swivel fittings are cheap insurance against future annoyance!

Here's what one tiny backhoe worth of hoses from Surplus Center looks like.

Some fittings were replaced due to thread damage.

Of course those tended to be the ones that were the hardest to see/access (why did the last guy screw them up in the first place? duh) so i had to find that out the hard way and straighten out a few hose end threads with a thread file. Which, i don't have an NPT thread file and all these hoses were 1/4 NPT, so i just figured out which metric thread was close enough to make up for with finesse. NPT is a bit weird because when you first start threading youre engaging the smallest male thread to the largest female thread so it seems easier than usual to screw up the first thread, but if you're threading by hand you can still tell when its not right. Nobody ever laid any threads over with the sheer power of the finger wrench, so the problem comes when you don't notice that it doesn't feel right, and start putting tools to it anyway! Which i apparently did at least once.

I also installed a bunch of NPT swivel fittings in locations where the hoses had been screwed directly into the cylinders, or into an elbow on the cylinder. For ~$3/each at surplus center these tiny swivel fittings are cheap insurance against future annoyance!

In the process of replacing all the hoses I noticed some extraneous fittings I didn't know the purpose of on a couple of the control valves. After some thinking i figured out those were the flow restrictor assemblies for the swing cylinders.

After i noticed that the swing speed seemed to me to be 'unrestricted' I came across this thread detailing the restrictors and decided to take mine apart to see why they weren't restricting. The following is basically me copying post #10 from that thread, detailing what i did to fix the restrictors:

When I opened mine, both of them had the hex-shaped restrictor plate rotated and with its sharp edges wedged into the circular 'seat' area above it.. both were stuck sitting diagonally instead of flat. Banging them upside down on the bench didn't dislodge them, so i got a proper size punch/dowel and popped them out.

To me it seemed that the main issue causing this failure mode was that the hex disc has too much vertical clearance between its seat and the ORB fitting screwed in above it, which allowed them to rotate. However, it didn't look like anything was missing, either.. I think this was a home-brew by some Aeroquip guy which, while clever, was slightly flawed.

To shrink the vertical clearance i simply found a stainless washer which was very close to the thread ID of the fitting and installed it between the hex disc and its 'seat'. The washer is essentially a wider seat which doesn't allow enough slack between the hex and the housing for the hex disc to rotate out of plane and jam one of its machined edges into something and get stuck. I didn't measure the thickness of the washer or how much clearance was left, just verified that it let the ORB fitting fully seat without trying to 'compress' the disc/washer assembly. The ID hole in the washer is probably almost as big as the ID of the 1/4" hoses it leads to, so i don't believe it actually restricts flow meaningfully on its own, just helps the hex disc do its job.

When i reassembled it, it does work and the swing is at an easy, safe speed now. I can't see how the current setup could ever fail so i believe it should be a permanent fix and very easy for anyone like me with a vast washer collection.. to replicate.

Here you can see the seat damage from the wedged in hex disc .

Washer and hex disc with restrictor orifice.

Washer installed over damaged seat, taking up excess clearance to prevent rotation of hex disc.

After that, they worked.

After i noticed that the swing speed seemed to me to be 'unrestricted' I came across this thread detailing the restrictors and decided to take mine apart to see why they weren't restricting. The following is basically me copying post #10 from that thread, detailing what i did to fix the restrictors:

When I opened mine, both of them had the hex-shaped restrictor plate rotated and with its sharp edges wedged into the circular 'seat' area above it.. both were stuck sitting diagonally instead of flat. Banging them upside down on the bench didn't dislodge them, so i got a proper size punch/dowel and popped them out.

To me it seemed that the main issue causing this failure mode was that the hex disc has too much vertical clearance between its seat and the ORB fitting screwed in above it, which allowed them to rotate. However, it didn't look like anything was missing, either.. I think this was a home-brew by some Aeroquip guy which, while clever, was slightly flawed.

To shrink the vertical clearance i simply found a stainless washer which was very close to the thread ID of the fitting and installed it between the hex disc and its 'seat'. The washer is essentially a wider seat which doesn't allow enough slack between the hex and the housing for the hex disc to rotate out of plane and jam one of its machined edges into something and get stuck. I didn't measure the thickness of the washer or how much clearance was left, just verified that it let the ORB fitting fully seat without trying to 'compress' the disc/washer assembly. The ID hole in the washer is probably almost as big as the ID of the 1/4" hoses it leads to, so i don't believe it actually restricts flow meaningfully on its own, just helps the hex disc do its job.

When i reassembled it, it does work and the swing is at an easy, safe speed now. I can't see how the current setup could ever fail so i believe it should be a permanent fix and very easy for anyone like me with a vast washer collection.. to replicate.

Here you can see the seat damage from the wedged in hex disc .

Washer and hex disc with restrictor orifice.

Washer installed over damaged seat, taking up excess clearance to prevent rotation of hex disc.

After that, they worked.

So the order in which i repaired the various sections of the backhoe really didnt make much sense in hindsight. Like i said, i was piecemealing it at first, but eventually realized i needed to take it all down to bits and repair and reassemble it one section or piece at a time.

In retelling the story, it seems to make more sense to me to start from the bottom up, so to speak.

So, I'll begin with the subframe. Basically every part of this B670 backhoe was damaged or worn out in one way or another. With the subframe, it was bent in several ways.

Apparently i either never took or somehow lost any pictures showing the subframe itself from any good angles. But, it is the section in the green box here:

It consists of some 3" channel pieces that form most of the length of it, with a large rectangular section made of 4" wide channel pieces at the rear. There is a ~1" round bar between the 3" channels which engages some hook shaped brackets bolted to the rear of the tractor. The 4" box section at the rear mounts most of the components in some way. The tank/control tower assembly bolts to the top of it with carriage bolts. The 'swing base' upper and lower mounting brackets attach to it. The bottom is welded, the top is bolted. The stabilizers/outriggers attach to it. The two single-acting swing cylinders attach to the inside of the rectangular section. It also mounts some 'skidplate' looking pieces at the bottom in case you drag it up over something. Bolted to the bottom rail in the rear there are also two 'bumpstops' which serve as travel limiters for the boom swing.

As far as what was wrong with it.. Well, as you may be able to see in the pic above, the 3" channel pieces were bent. One side was bent very minorly, but the other side was bent bad enough that i felt the need to fix it. The bend can be seen here:

I fixed this by making relief cuts, banging the thing back into place with a 4lb sledge and welding the cuts back up. The section of 3" channel behind the 1" round bar was not bent, so my relief cuts were made just in front of the round bar, basically centered in the bent section. I believe i made two different relief cuts, one to bend the channel laterally, and then a different one to bend it vertically. Here's a picture of a funny way to make a cut..

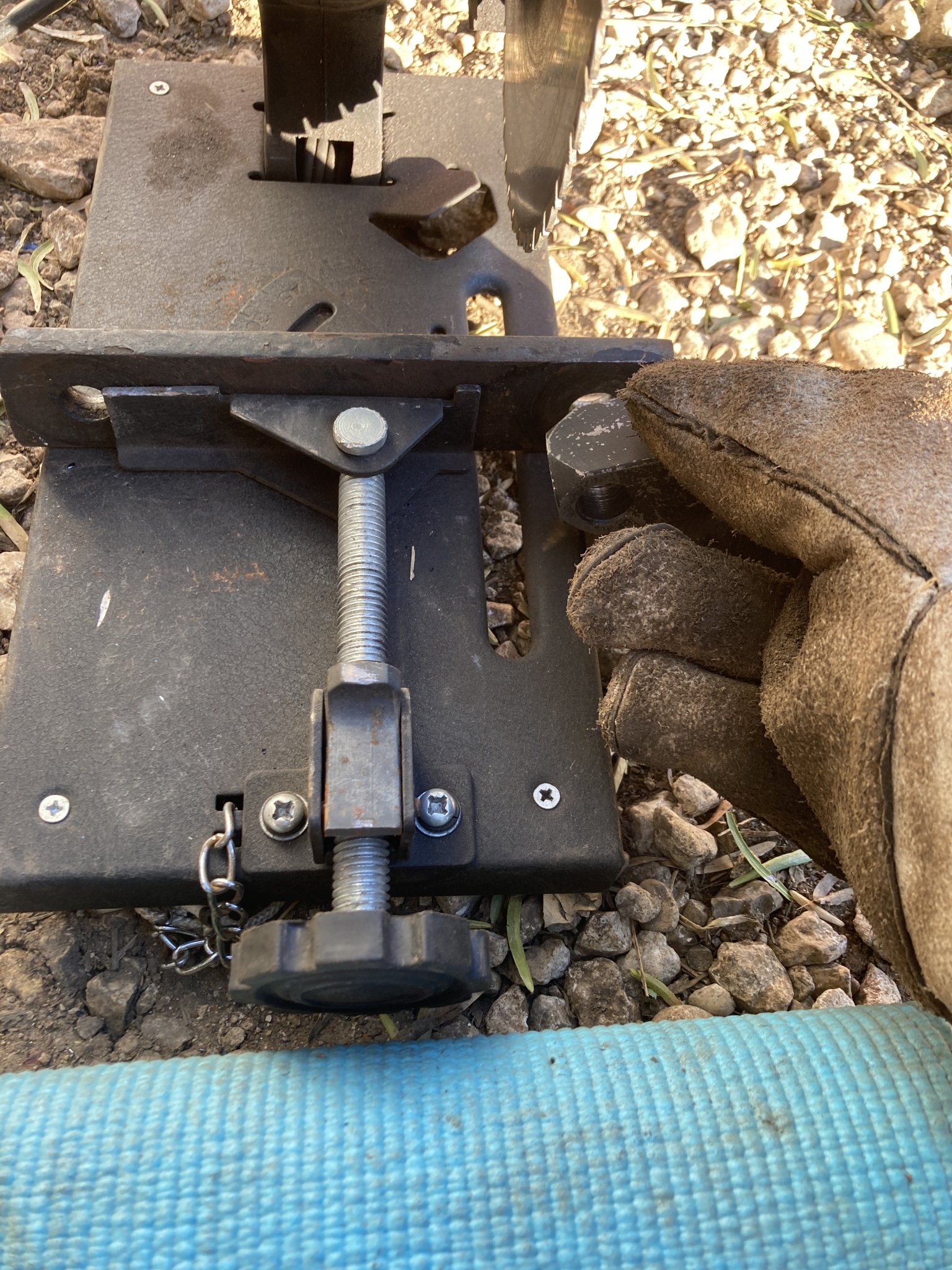

After making the cuts, I needed to 'realign' the two channel sections. I invented a silly way of doing this. I used a piece of threaded rod through two mounting holes at the very front of the channel sections. On the threaded rod i used, essentially, 'threaded washers' which i'd scrounged from some incomplete special tool or other that hit the junk pile at my place of work.

The threaded washers were thick enough that they didn't have a lot of wobble aka lateral runout to them. This let me judge whether the rail sections were parallel in all directions, or close enough to it anyway. You can see what i mean about how the rail would meet the washer in these pics:

I measured the inside to inside width between the channels where the 1" round bar was welded and set the inside washers to be that width so that the rails were parallel. By a combination of tightening the nuts on the outsides of channel to bend past the correct point and then relax back to it, and banging things around enthusiastically with two-handed swings of the 4lb hand sledge, i was able to get the channel sections to naturally sit at the proper width AND square to each other. I think i used some blocking in between the two rails to encourage it to bend where i wanted it to rather than installing a brand new bend somewhere else. It all worked out well and i welded the relief cuts back up, which luckily did not ruin my alignment. This was all optional and it was already proven to fit and function in bent form anyway, but it bothered me and i fixed it.

In retelling the story, it seems to make more sense to me to start from the bottom up, so to speak.

So, I'll begin with the subframe. Basically every part of this B670 backhoe was damaged or worn out in one way or another. With the subframe, it was bent in several ways.

Apparently i either never took or somehow lost any pictures showing the subframe itself from any good angles. But, it is the section in the green box here:

It consists of some 3" channel pieces that form most of the length of it, with a large rectangular section made of 4" wide channel pieces at the rear. There is a ~1" round bar between the 3" channels which engages some hook shaped brackets bolted to the rear of the tractor. The 4" box section at the rear mounts most of the components in some way. The tank/control tower assembly bolts to the top of it with carriage bolts. The 'swing base' upper and lower mounting brackets attach to it. The bottom is welded, the top is bolted. The stabilizers/outriggers attach to it. The two single-acting swing cylinders attach to the inside of the rectangular section. It also mounts some 'skidplate' looking pieces at the bottom in case you drag it up over something. Bolted to the bottom rail in the rear there are also two 'bumpstops' which serve as travel limiters for the boom swing.

As far as what was wrong with it.. Well, as you may be able to see in the pic above, the 3" channel pieces were bent. One side was bent very minorly, but the other side was bent bad enough that i felt the need to fix it. The bend can be seen here:

I fixed this by making relief cuts, banging the thing back into place with a 4lb sledge and welding the cuts back up. The section of 3" channel behind the 1" round bar was not bent, so my relief cuts were made just in front of the round bar, basically centered in the bent section. I believe i made two different relief cuts, one to bend the channel laterally, and then a different one to bend it vertically. Here's a picture of a funny way to make a cut..

After making the cuts, I needed to 'realign' the two channel sections. I invented a silly way of doing this. I used a piece of threaded rod through two mounting holes at the very front of the channel sections. On the threaded rod i used, essentially, 'threaded washers' which i'd scrounged from some incomplete special tool or other that hit the junk pile at my place of work.

The threaded washers were thick enough that they didn't have a lot of wobble aka lateral runout to them. This let me judge whether the rail sections were parallel in all directions, or close enough to it anyway. You can see what i mean about how the rail would meet the washer in these pics:

I measured the inside to inside width between the channels where the 1" round bar was welded and set the inside washers to be that width so that the rails were parallel. By a combination of tightening the nuts on the outsides of channel to bend past the correct point and then relax back to it, and banging things around enthusiastically with two-handed swings of the 4lb hand sledge, i was able to get the channel sections to naturally sit at the proper width AND square to each other. I think i used some blocking in between the two rails to encourage it to bend where i wanted it to rather than installing a brand new bend somewhere else. It all worked out well and i welded the relief cuts back up, which luckily did not ruin my alignment. This was all optional and it was already proven to fit and function in bent form anyway, but it bothered me and i fixed it.

Another small issue with the subframe was divots worn into the round bar where it interfaced with the mounting brackets on the tractor. I welded those up and then flap disced them down smooth. It's not a perfectly round surface but it's a lot better than it was.

The inside of the C-shaped notch on the tractor brackets would have been a lot harder for me to freehand back into proper shape after welding, and they didn't look that bad anyway so that side of this interface was not touched..

Another issue with the subframe was the 'swing base' mounting brackets.. The lower mount plate was bent, making the upper and lower bushings misaligned with each other. Luckily they had 'worn in' to this misalignment without seriously messing up the 'pins' of the swing base, and hadn't gone 100% through to rub steel on steel. But, i didn't realize the seriousness of the misalignment issue until AFTER I had pressed in the new bushings and realized how far the swing base was from lining up to go back together.. So these pics show new bushings installed even though i haven't talked about the whole bushing thing yet.

Here's how far off the bolted top mount bracket wanted to sit when the swing base was sitting in the brand new bushing in the lower bracket.. Yeah, not close.

Here's the lower bracket with new bushing installed. The band of discoloration and distinct lack of orange paint in the area hint at past trauma and 'adjustments'.

\

\

Oh, there's also.. this.. on the other side:

Which, even though it looked like shit, really WAS on there. I can knock 'not really welded' stuff right the hell off with my good friend the 4lb hand sledge, but this thing didn't budge.. Ok, so we're keeping it. Unfortunately, whoever put it there didn't do THIS step first:

Which is, you know, taking ANY kind of an improvised straight edge to it to make sure it was actually flat-ish before you weld a hefty chunk of steel onto it! Ugh.

So, i did my best to straighten it. I got it close enough that the upper bracket could be bolted normally and the swing base could be rotated in the new bushings by hand, although not as easily as i would wish. I later sort of 'boxed in' the bottom of the lower bracket with pieces of angle iron and flat bar.. will look for pics of that, not seeing them right now.

The inside of the C-shaped notch on the tractor brackets would have been a lot harder for me to freehand back into proper shape after welding, and they didn't look that bad anyway so that side of this interface was not touched..

Another issue with the subframe was the 'swing base' mounting brackets.. The lower mount plate was bent, making the upper and lower bushings misaligned with each other. Luckily they had 'worn in' to this misalignment without seriously messing up the 'pins' of the swing base, and hadn't gone 100% through to rub steel on steel. But, i didn't realize the seriousness of the misalignment issue until AFTER I had pressed in the new bushings and realized how far the swing base was from lining up to go back together.. So these pics show new bushings installed even though i haven't talked about the whole bushing thing yet.

Here's how far off the bolted top mount bracket wanted to sit when the swing base was sitting in the brand new bushing in the lower bracket.. Yeah, not close.

Here's the lower bracket with new bushing installed. The band of discoloration and distinct lack of orange paint in the area hint at past trauma and 'adjustments'.

Oh, there's also.. this.. on the other side:

Which, even though it looked like shit, really WAS on there. I can knock 'not really welded' stuff right the hell off with my good friend the 4lb hand sledge, but this thing didn't budge.. Ok, so we're keeping it. Unfortunately, whoever put it there didn't do THIS step first:

Which is, you know, taking ANY kind of an improvised straight edge to it to make sure it was actually flat-ish before you weld a hefty chunk of steel onto it! Ugh.

So, i did my best to straighten it. I got it close enough that the upper bracket could be bolted normally and the swing base could be rotated in the new bushings by hand, although not as easily as i would wish. I later sort of 'boxed in' the bottom of the lower bracket with pieces of angle iron and flat bar.. will look for pics of that, not seeing them right now.

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Looking good so far.

You have checked out this thread, correct? Lots of good info.

www.orangetractortalks.com

www.orangetractortalks.com

Very typical of these backhoes. They weren't very stout or well engineered to begin with, so decades of neglect & abuse really take their toll.Basically every part of this B670 backhoe was damaged or worn out in one way or another. With the subframe, it was bent in several ways.

You have checked out this thread, correct? Lots of good info.

B670 Backhoe Rebuild

Does anyone have a working knowledge of the older B670 (KUW200) backhoes that were made for the older B6100 Kubota tractors. I am trying to rebuild one and have found that the area that the bottom pin of the swing weldment goes into is worn out and out of round. The raised round piece of metal...

Yes! That thread was very helpful in many ways, especially in just helping me gain confidence to take this work on in general.You have checked out this thread, correct? Lots of good info.

This rehab was not to the extent of doing any machine work whatsoever, but given the tool and experience constraints it turned out well in my opinion.

Another are of the subframe that needed a lot of improvement was the brackets for the stabilizers, or outriggers. Not only was one of the stabilizers bent, but the mounting brackets on both sides were seriously distorted. This pic gives some idea:

They were all about like that. For a little more context on the misalignment and flex issues, here's the pins that came out:

And after a little cleaning:

So clearly those get replaced, but first step is to bend the bracketry back. That was a bit ambitious for me with no torch to heat anything first, but I did get it done.

With the subframe still on the tractor, I used a tow hook from some random car which is basically a very heavy duty eyelet bolt, through the bushing, and then used a come along to an area further ahead on the subframe and loaded that up as much as i thought it would take.

That by itself was not enough to bend the bracket, so i added universal flange bending tool, which is a giant crescent wrench that i simply cinch down and then wham the end of it with the hand sledge. This tool is extremely cheap at Harbor Freight and was purchased long ago with the express intent of beating the end of it with a hand sledge. Usually stuck fan clutches, and the occasional metal bending.

That got it done!

Of course, there's no point unbending any of it unless i do something to prevent it from reoccurring. So, I took a very unscientific but time-tested approach: Add Triangles.

After fully articulating the stabilizers to check clearance on the inside of the bracket, i determined i could add a piece of angle iron inside the bracket to stabilize it somewhat there.

So, one of those was welded in on each side.

I also added triangles to the front of the front flange. As you can see from this beautiful pile of materials, i enjoy reusing scraps of metal.

You can also see the installed angle irons there.

Last edited:

So one of the things i learned from THIS project, out of all the projects i've ever done.. THIS project finally made me realize i do dumb things when i work tired. This project happened during an extremely busy time in my life, which is why it took a year (with long breaks in between bursts of progress), why it mostly happened at night, why i forgot to take pictures of some things, etc etc.

So i cut these pieces of angle iron to use as braces, a total of 4 pieces, 2 for each side.

So what's the problem? Well, when i went to weld them on i must have spaced out, and installed them 'facing up', i.e. i turned them into little cups which would collect water. That annoyed me, so i drilled drain holes through them and then cut MORE triangles (just flat stock this time, not more angle) and then welded those over top to make 'box' sections. Except that with my slight lack of fitup skills and patience, it ended up looking like hot garbage compared to if i had cut whole box sections in the first place, or if i had just welded the angle iron on facing downward like i should have done from the beginning! Ugh. So, whatever. It's a bit ugly.

And... now i cant find a single pic showing them installed? Idiot. Im gonna drive to my buddy's house at some point and retake all the pics that somehow went missing, but for now here's a truly terrible angle i snipped out of a different pic, sort of showing 1 out of 4 installed braces.

Right.. onwards..

One of the things i didn't like about how this backhoe operated was how 'loosely attached' it seemed to be to the tractor. You sit on the tractor, but operate the hoe, and you can feel all kinds of relative movement between the two pieces, and it irritated me. Part of improving that was welding up the divots in the round tube which engaged to the brackets on the tractor. You can sort of see that interface here:

Remember that one of those notched brackets was missing when the tractor was purchased? Well, when i went to install it i realized i had an appropriate bolt but no appropriate nut. Funnily enough, it turned out the cheapest nut for that thread size which could be had with 2-day shipping on Amazon, was a coupling nut, in other words a very deep/tall nut. No problem, i thought, ill just chop it in half on the chop saw and have matching nuts for both sides! Then i got lazy and left it exactly as you see it, with the odd looking mismatched hardware.

Anyway, i didn't like all the slop in the tractor-to-backhoe connection, and filling in divots on the round bar wasn't enough to be rid of it. So, i decided to invent a sort of 'top link' which would preload the subframe into its notches just enough to get rid of the slop. Many subframe backhoes have something like this anyway, but this design had nothing.

Spitballing the layout. This space is actually pretty tight on such a small backhoe, with the tank/control tower assembly, oil filter, and pto pump all fighting for space here. But it would work. Now, this is opening a big can of worms of possible discussion because it relates to 'why do 3pt backhoes (with careless/unknowing operators) break tractors and subframe backhoes don't'.

Basically, when you dig with a backhoe, your downward force on the bucket is an upward force on the 'base' of the backhoe, which gets transferred to the rear of the tractor as a lifting force. If you lift the back of a tractor, you put the entire underside of the tractor in tension, and the topside in compression. The tractor has near-unlimited strength in compression, at least in this context. But, in tension the only strength holding the tractor together is the various bolted flanges between sections. These are usually cast material (brittle), with only bolt heads or perhaps small washers transferring all the tensile force into the flange (high local loading), and the bolted flange itself is usually cantilevered to some extent, meaning if it's allowed to deflect at all it will create another bending force where that flange 'turns the corner' to the body of that housing, etc. This is where the failure will start that leads to broken tractors.

A subframe gets around this by putting the force into the tractor differently. You can imagine it similarly to you being a wounded soldier needing evacuated. If you are laying on the ground and someone simply picks up your feet, your body will flex in the middle unless you exert great strength to stop it. One side in tension, one side in compression, yadda yadda. However, if someone puts a stretcher under you and picks up one end of that, you will flex much less because the stretcher has its own structure to take that, and you mostly experience a straight up lifting force. The subframe does that for the tractor.

So the reason this top link thing is relevant to that 3pt backhoe vs subframe backhoe thing is that if you preload it the wrong way you go right back to putting the whole bottom of the tractor under tension. Now, the subframe would probably still prevent the 'broken tractor', but in my mind theres a 'better' way to preload this top link thingy, and a worse way. Point being i had to think about all this before deciding whether a theoretical top link design was actually a good idea. I decided, for myself anyway, that it was and continued on.

Now to turn a chunk of black pipe into a top link. It needed to be adjustable. I had a cheesy cat0 top link which had bent enough that it wouldn't thread any more, which i had already cut the ball ends off of and welded them onto something else. In this case i don't need many inches of adjustment as a 3pt top link would.. just maybe ~1/2" or so to take the slack out of the subframe/bracket interface. That's 1/2" of travel in this link, not that the subframe/bracket interface has 1/2" of slack, mind you. So, i simply chopped off the section of thread that was bent and would have been more trouble than it was worth to fix, straightened the rest 'enough' in the press, and had myself a big ol turnbuckle thingy.

Since this tractor project was essentially a 'test run' of a bunch of things i would like to implement again elsewhere, one of the things i did several times was add grease fittings to things which previously didn't have them. So, i drilled holes in the threaded ends of the turnbuckle center section.

These holes don't need to be very big because grease gets pumped around at very high pressure just by the hand pump on a grease gun. It will flow through almost any gap. So, a fairly small hole. The tube itself is not thick/deep enough to take the threads of the grease fitting, but the simple fix for that which i used many times on this tractor, is to simply weld an appropriately threaded nut over top of the hole. Usually this is because the hole is damaged beyond easy repair, but in this case it's just because the material beneath is too thin to be threaded. I used 1/4-28 grease fittings everywhere on this thing, so 1/4-28 nuts is what this takes.

Insert disclaimer about welding over Zinc, etc etc. Nuts welded on, fittings inserted.

So i cut these pieces of angle iron to use as braces, a total of 4 pieces, 2 for each side.

So what's the problem? Well, when i went to weld them on i must have spaced out, and installed them 'facing up', i.e. i turned them into little cups which would collect water. That annoyed me, so i drilled drain holes through them and then cut MORE triangles (just flat stock this time, not more angle) and then welded those over top to make 'box' sections. Except that with my slight lack of fitup skills and patience, it ended up looking like hot garbage compared to if i had cut whole box sections in the first place, or if i had just welded the angle iron on facing downward like i should have done from the beginning! Ugh. So, whatever. It's a bit ugly.

And... now i cant find a single pic showing them installed? Idiot. Im gonna drive to my buddy's house at some point and retake all the pics that somehow went missing, but for now here's a truly terrible angle i snipped out of a different pic, sort of showing 1 out of 4 installed braces.

Right.. onwards..

One of the things i didn't like about how this backhoe operated was how 'loosely attached' it seemed to be to the tractor. You sit on the tractor, but operate the hoe, and you can feel all kinds of relative movement between the two pieces, and it irritated me. Part of improving that was welding up the divots in the round tube which engaged to the brackets on the tractor. You can sort of see that interface here:

Remember that one of those notched brackets was missing when the tractor was purchased? Well, when i went to install it i realized i had an appropriate bolt but no appropriate nut. Funnily enough, it turned out the cheapest nut for that thread size which could be had with 2-day shipping on Amazon, was a coupling nut, in other words a very deep/tall nut. No problem, i thought, ill just chop it in half on the chop saw and have matching nuts for both sides! Then i got lazy and left it exactly as you see it, with the odd looking mismatched hardware.

Anyway, i didn't like all the slop in the tractor-to-backhoe connection, and filling in divots on the round bar wasn't enough to be rid of it. So, i decided to invent a sort of 'top link' which would preload the subframe into its notches just enough to get rid of the slop. Many subframe backhoes have something like this anyway, but this design had nothing.

Spitballing the layout. This space is actually pretty tight on such a small backhoe, with the tank/control tower assembly, oil filter, and pto pump all fighting for space here. But it would work. Now, this is opening a big can of worms of possible discussion because it relates to 'why do 3pt backhoes (with careless/unknowing operators) break tractors and subframe backhoes don't'.

Basically, when you dig with a backhoe, your downward force on the bucket is an upward force on the 'base' of the backhoe, which gets transferred to the rear of the tractor as a lifting force. If you lift the back of a tractor, you put the entire underside of the tractor in tension, and the topside in compression. The tractor has near-unlimited strength in compression, at least in this context. But, in tension the only strength holding the tractor together is the various bolted flanges between sections. These are usually cast material (brittle), with only bolt heads or perhaps small washers transferring all the tensile force into the flange (high local loading), and the bolted flange itself is usually cantilevered to some extent, meaning if it's allowed to deflect at all it will create another bending force where that flange 'turns the corner' to the body of that housing, etc. This is where the failure will start that leads to broken tractors.

A subframe gets around this by putting the force into the tractor differently. You can imagine it similarly to you being a wounded soldier needing evacuated. If you are laying on the ground and someone simply picks up your feet, your body will flex in the middle unless you exert great strength to stop it. One side in tension, one side in compression, yadda yadda. However, if someone puts a stretcher under you and picks up one end of that, you will flex much less because the stretcher has its own structure to take that, and you mostly experience a straight up lifting force. The subframe does that for the tractor.

So the reason this top link thing is relevant to that 3pt backhoe vs subframe backhoe thing is that if you preload it the wrong way you go right back to putting the whole bottom of the tractor under tension. Now, the subframe would probably still prevent the 'broken tractor', but in my mind theres a 'better' way to preload this top link thingy, and a worse way. Point being i had to think about all this before deciding whether a theoretical top link design was actually a good idea. I decided, for myself anyway, that it was and continued on.

Now to turn a chunk of black pipe into a top link. It needed to be adjustable. I had a cheesy cat0 top link which had bent enough that it wouldn't thread any more, which i had already cut the ball ends off of and welded them onto something else. In this case i don't need many inches of adjustment as a 3pt top link would.. just maybe ~1/2" or so to take the slack out of the subframe/bracket interface. That's 1/2" of travel in this link, not that the subframe/bracket interface has 1/2" of slack, mind you. So, i simply chopped off the section of thread that was bent and would have been more trouble than it was worth to fix, straightened the rest 'enough' in the press, and had myself a big ol turnbuckle thingy.

Since this tractor project was essentially a 'test run' of a bunch of things i would like to implement again elsewhere, one of the things i did several times was add grease fittings to things which previously didn't have them. So, i drilled holes in the threaded ends of the turnbuckle center section.

These holes don't need to be very big because grease gets pumped around at very high pressure just by the hand pump on a grease gun. It will flow through almost any gap. So, a fairly small hole. The tube itself is not thick/deep enough to take the threads of the grease fitting, but the simple fix for that which i used many times on this tractor, is to simply weld an appropriately threaded nut over top of the hole. Usually this is because the hole is damaged beyond easy repair, but in this case it's just because the material beneath is too thin to be threaded. I used 1/4-28 grease fittings everywhere on this thing, so 1/4-28 nuts is what this takes.

Insert disclaimer about welding over Zinc, etc etc. Nuts welded on, fittings inserted.

Last edited:

Next was to somehow connect this blunt-ended turnbuckle to the subframe and tractor. The tractor end is pretty easy because I was able to use the stock top link bracket. That has its limits, but I considered it perfectly good for what i was doing here.

On the bottom, no attachment point existed. I decided to create a bracket the lazy way, by which i mean this: instead of drilling 2 nice holes in thick material, i just used the chop saw to chop two ends off a random bracket which already had nice, perfectly located holes.

Also seen there, a threaded 'rod end' from one of the electro-hydraulic cylinders i converted to a power top link for my own B6100. I actually welded the ball ends i chopped off this top link to make that a proper top link, and used this non-articulating cross-pin rod end for the base of this link because the hole size matched the bracket i wanted to use. Another perfectly located and finished hole i didn't have to drill.

I used a grade 8 bolt that had an unthreaded shank the right length that it would make a good 'pin'. In other words the threads only start right inside that bracket but the vast majority of it going through all that is smooth. Those threads in the rod end are metric m16 by something or other. Not useful to me, so i simply welded the pipe to it.

I guess i don't have any pictures of how i got those pieces square, but this method was convenient and worked well enough for the job of getting the pipe welded to the turnbuckle ends squarely.

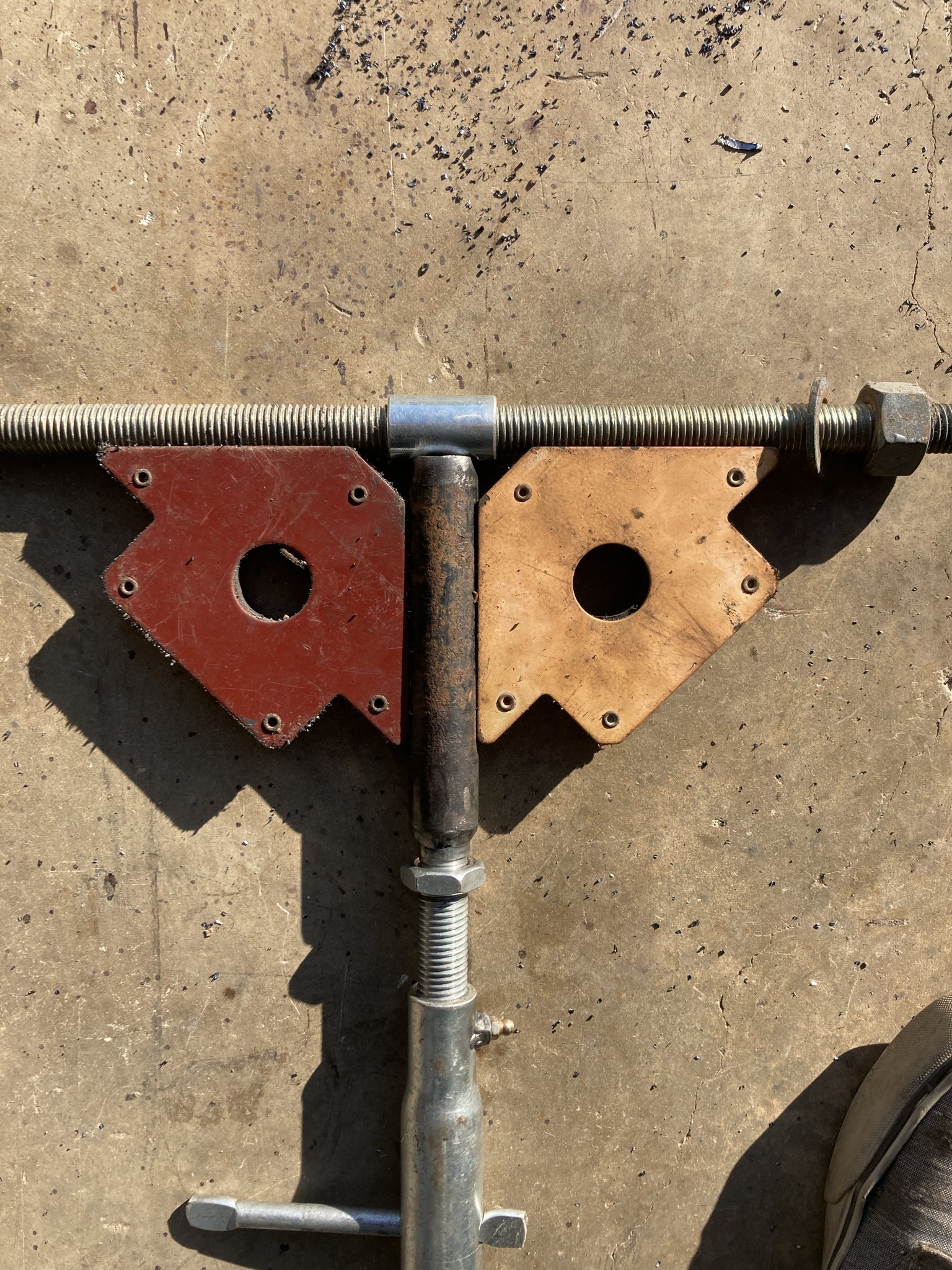

For the tractor end of things, i planned to use the existing top link bracket which meant 3/4" pin size. I happened to have a couple of 3/4" to 1" bushings which you can get online or at tractor supply for a couple of bucks, so i used one of those for the crosspin rod end up there. I notched the pipe for it freehand, but with pieces this small its pretty easy to get a gap small enough to weld across even if the fitup isn't perfect.

Trick there was to make sure my notch ended up square to the tube. Luckily some 3/4" threaded rod and another easy magnet trick got me close enough.

And, the finished product.

I decided to reuse one of the stock pins from the loader (which had been replaced with new). In this location the wear on the pin didn't overlap with where it engaged this different bracket so it was essentially a 'good' pin if used here. I dressed the end up with the handheld belt sander. I used that and a bigger 4x36 belt sander to dress up basically all the pins i reused or repurposed, even some i made from scratch.

I welded that big washer on it for some reason.. i guess as a depth stopper. Sometimes i just do too much. Anyway, i made a top link. Once i had the backhoe complete again I could no longer feel movement between the tractor and the backhoe.

On the bottom, no attachment point existed. I decided to create a bracket the lazy way, by which i mean this: instead of drilling 2 nice holes in thick material, i just used the chop saw to chop two ends off a random bracket which already had nice, perfectly located holes.

Also seen there, a threaded 'rod end' from one of the electro-hydraulic cylinders i converted to a power top link for my own B6100. I actually welded the ball ends i chopped off this top link to make that a proper top link, and used this non-articulating cross-pin rod end for the base of this link because the hole size matched the bracket i wanted to use. Another perfectly located and finished hole i didn't have to drill.

I used a grade 8 bolt that had an unthreaded shank the right length that it would make a good 'pin'. In other words the threads only start right inside that bracket but the vast majority of it going through all that is smooth. Those threads in the rod end are metric m16 by something or other. Not useful to me, so i simply welded the pipe to it.

I guess i don't have any pictures of how i got those pieces square, but this method was convenient and worked well enough for the job of getting the pipe welded to the turnbuckle ends squarely.

For the tractor end of things, i planned to use the existing top link bracket which meant 3/4" pin size. I happened to have a couple of 3/4" to 1" bushings which you can get online or at tractor supply for a couple of bucks, so i used one of those for the crosspin rod end up there. I notched the pipe for it freehand, but with pieces this small its pretty easy to get a gap small enough to weld across even if the fitup isn't perfect.

Trick there was to make sure my notch ended up square to the tube. Luckily some 3/4" threaded rod and another easy magnet trick got me close enough.

And, the finished product.

I decided to reuse one of the stock pins from the loader (which had been replaced with new). In this location the wear on the pin didn't overlap with where it engaged this different bracket so it was essentially a 'good' pin if used here. I dressed the end up with the handheld belt sander. I used that and a bigger 4x36 belt sander to dress up basically all the pins i reused or repurposed, even some i made from scratch.

I welded that big washer on it for some reason.. i guess as a depth stopper. Sometimes i just do too much. Anyway, i made a top link. Once i had the backhoe complete again I could no longer feel movement between the tractor and the backhoe.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

DON"T do the top link stiffener you will break the cylinder housing!

That is one of the weakest points of that system!

That is one of the weakest points of that system!

I guess if my buddy's 3pt cylinder housing breaks i'll have to give him some parts off my parts tractor. I honestly don't expect it to, though. The way i set that link up was under tension. That pulls the round bar on the backhoe subframe against the top of the notch in the mounting brackets. That puts the top link bracket in slight tension, but puts the cylinder housing in compression to the tractor due to the steep downward angle of the link. I suspect the amount of tension is FAR less than simply carrying a lifted bush hog over bumpy terrain for example, which is enough to do accidental wheelies unless you've added front weight, and all of that is from tension on the top link. It also should not change much during use and be a pretty 'static' force. Since the backhoe is already contacting the 'top' of the mounting brackets, it shouldn't be able to move any further that direction from the force of digging, not even enough to relieve the tension on the top link, let alone actually push on it.

But i absolutely see the danger of putting the top link in compression, because that would leave slack in the C-notches of the mounting brackets, and any upward force from pushing down with the bucket or stabilizers would essentially be lifting the tractor entirely from the top link bracket or 3pt cylinder housing until something gave enough to let the round bar hit the top of the bracket notches. If the top link didn't bend that would mean ripping the 3pt cylinder off the top of the tractor.. So, certainly good advice in terms of unintended consequences of setting it up in compression!

The only situation where i could see the top link being put under more than the 'static' force of it being set the way it is, is if someone was travelling with the stabilizers up and something hanging off the bucket/boom. That would be similar to the carrying a lifted bush hog example. But, when the stabilizers are down, using a lifting force on the boom/bucket would make the stabilizers a fulcrum point and end up creating an upward force where the front of the backhoe subframe attaches to the loader subframe, essentially lifting in the middle of the tractor. I suspect that any time the stabilizers are down, the amount of tension the top link bracket would experience is 100% survivable, especially since the link itself is always at such a downward angle that it compresses the cylinder housing to the tractor, unlike say the lifted bush hog which is putting the bracket under tension and the top link being at an upward angle is creating a lifting/tensile force on the cylinder housing.

That's how i rationalized all of it.. I'm certainly open to discussion. I'm curious if you've seen multiple failures of that housing ripping away from the tractor? If so, which direction was the pull that failed it?

But i absolutely see the danger of putting the top link in compression, because that would leave slack in the C-notches of the mounting brackets, and any upward force from pushing down with the bucket or stabilizers would essentially be lifting the tractor entirely from the top link bracket or 3pt cylinder housing until something gave enough to let the round bar hit the top of the bracket notches. If the top link didn't bend that would mean ripping the 3pt cylinder off the top of the tractor.. So, certainly good advice in terms of unintended consequences of setting it up in compression!

The only situation where i could see the top link being put under more than the 'static' force of it being set the way it is, is if someone was travelling with the stabilizers up and something hanging off the bucket/boom. That would be similar to the carrying a lifted bush hog example. But, when the stabilizers are down, using a lifting force on the boom/bucket would make the stabilizers a fulcrum point and end up creating an upward force where the front of the backhoe subframe attaches to the loader subframe, essentially lifting in the middle of the tractor. I suspect that any time the stabilizers are down, the amount of tension the top link bracket would experience is 100% survivable, especially since the link itself is always at such a downward angle that it compresses the cylinder housing to the tractor, unlike say the lifted bush hog which is putting the bracket under tension and the top link being at an upward angle is creating a lifting/tensile force on the cylinder housing.

That's how i rationalized all of it.. I'm certainly open to discussion. I'm curious if you've seen multiple failures of that housing ripping away from the tractor? If so, which direction was the pull that failed it?

Last edited:

Runs With Scissors

Well-known member

Equipment

L2501 TLB , Grappel, Brush Hog, Box Blade, Ballast box, Forks, Tiller, PH digger

Wow Vigo, you are one dedicated person for sure!!!

Kudos to you sir. There is no way I could have tackled a project that big.

Nice write up, and thanks for sharing!

Kudos to you sir. There is no way I could have tackled a project that big.

Nice write up, and thanks for sharing!

So with the subframe itself repaired and.. upgraded..? I dunno, anyway with that part done let's start building stuff onto it.

The stabilizer arms (which i always used to call outriggers but im trying to retrain myself) had issues. One was pretty well bent, and both had some issues with the pin bosses being worn and bent. So basically everything from the brackets on the subframe, to the pin brackets on the arms, the pins themselves, to one of the arms themselves, was bent up. Seems to be a pretty resounding set of clues that the design itself was not strong enough. So, having reinforced the subframe brackets, it was now time to do something to reinforce the arms and their pin brackets.

Here you can see the stabilizer arms laid up next to each other and the bend in one is obvious. They are made of 3" channel section.

And here was my plan to reinforce them.. literal bed frame. Pieces of 2x2x3/16 angle iron from one of those power-angling bed frames that i broke down to parts after my cousin broke one of the linear actuators and got a whole new bed.

In order to unbend the stabilizer arm (which was bent in two planes) i first just pushed it back as close to flat as i could with the press.

Obviously that did not fix everything, not even close. But the section of 3" channel between that bend and the pin holes was not bent and neither was my 2x2 angle iron, so i went ahead and joined them there and then used the angle as a 'reference' of how to bend the arm the rest of the way before tacking them together. I knew i needed a relief cut, so i made that and then stuck it all back in the press for 'alignment'.

In the pic below you can see that the press is being used to flex the arm 'laterally', and there is actually a coil spring compressor clamp on the end of it (you can sort of see the grey hooks) being used as a form of C-clamp (that wouldn't slide off the 'peak' of the angle iron) to draw the two pieces together in the other direction so i could tack them together.

Then came a whole bunch of stitch welding. Since im recalling these events out of order, these were actually some of the first real welds i did on the tractor. I had problems with them cracking that i assumed meant i had it TOO hot. Once i finally googled it and found it wasnt hot enough, i had them welded solid in no time.

Down at the end of the arm where the 'pad' pivots on the end of it, it had to taper the end of the angle iron to allow the pads to articulate normally without hitting the angle iron.

Continued...

The stabilizer arms (which i always used to call outriggers but im trying to retrain myself) had issues. One was pretty well bent, and both had some issues with the pin bosses being worn and bent. So basically everything from the brackets on the subframe, to the pin brackets on the arms, the pins themselves, to one of the arms themselves, was bent up. Seems to be a pretty resounding set of clues that the design itself was not strong enough. So, having reinforced the subframe brackets, it was now time to do something to reinforce the arms and their pin brackets.

Here you can see the stabilizer arms laid up next to each other and the bend in one is obvious. They are made of 3" channel section.

And here was my plan to reinforce them.. literal bed frame. Pieces of 2x2x3/16 angle iron from one of those power-angling bed frames that i broke down to parts after my cousin broke one of the linear actuators and got a whole new bed.

In order to unbend the stabilizer arm (which was bent in two planes) i first just pushed it back as close to flat as i could with the press.

Obviously that did not fix everything, not even close. But the section of 3" channel between that bend and the pin holes was not bent and neither was my 2x2 angle iron, so i went ahead and joined them there and then used the angle as a 'reference' of how to bend the arm the rest of the way before tacking them together. I knew i needed a relief cut, so i made that and then stuck it all back in the press for 'alignment'.

In the pic below you can see that the press is being used to flex the arm 'laterally', and there is actually a coil spring compressor clamp on the end of it (you can sort of see the grey hooks) being used as a form of C-clamp (that wouldn't slide off the 'peak' of the angle iron) to draw the two pieces together in the other direction so i could tack them together.

Then came a whole bunch of stitch welding. Since im recalling these events out of order, these were actually some of the first real welds i did on the tractor. I had problems with them cracking that i assumed meant i had it TOO hot. Once i finally googled it and found it wasnt hot enough, i had them welded solid in no time.

Down at the end of the arm where the 'pad' pivots on the end of it, it had to taper the end of the angle iron to allow the pads to articulate normally without hitting the angle iron.

Continued...

That end looked a little fragile to me too, even though the pin brackets weren't really bent in any meaningful way that was hurting function. Still, I put them in the press and bent them back.

Then i cut small pieces of angle iron and welded them in as braces. Also bed frame.

Then onto the other end which attaches to the tractor. The pin brackets were slightly bent, so i put them in the press and pressed them a little bit, also using the press as just a vise to hold it while i yanked down on the other end of the arm until i had them bent back the way i wanted.

THEN.. i made silly decisions which added great tedium to my process. Instead of using repair bushings or some kind of properly fitting pin sleeve to repair and brace these brackets, i used a combination of random black pipe, 5/8-to-3/4 spacers (pins are 5/8") which are really too thin for comfortable mig welding at 1/16" wall thickness.. and large but similarly thin flat washers. In retrospect.. what the hell was i thinking.

Here's what i did with the black pipe..

And here's what i did with the spacers and washers after drilling the pin brackets out to 3/4" to accept the spacers.

If that looks tricky to weld together without burning up, well it was.

Then i cut small pieces of angle iron and welded them in as braces. Also bed frame.

Then onto the other end which attaches to the tractor. The pin brackets were slightly bent, so i put them in the press and pressed them a little bit, also using the press as just a vise to hold it while i yanked down on the other end of the arm until i had them bent back the way i wanted.

THEN.. i made silly decisions which added great tedium to my process. Instead of using repair bushings or some kind of properly fitting pin sleeve to repair and brace these brackets, i used a combination of random black pipe, 5/8-to-3/4 spacers (pins are 5/8") which are really too thin for comfortable mig welding at 1/16" wall thickness.. and large but similarly thin flat washers. In retrospect.. what the hell was i thinking.

Here's what i did with the black pipe..

And here's what i did with the spacers and washers after drilling the pin brackets out to 3/4" to accept the spacers.

If that looks tricky to weld together without burning up, well it was.

Last edited:

If that looks tricky to weld together without burning up, well it was.

I snorted a little. I'm loving this project.