Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

My B670 Hoe swing speed is WAY too fast- like 1 second from center to 90 degrees, if you just shove the lever over.

This requires VERY careful, slow feathering when swinging side to side. I would like to ad restrictors to slow this way down, and was looking at the hose/valve/cylinder layout to decide where to put the restrictors in. The swing cylinders are single acting, so I thought the best location for a restrictor would be where the line connects to the cylinder.

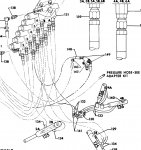

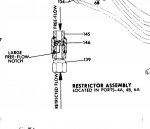

Looking at the diagram, it appears there are supposed to be restrictors at that location.

Drawing shows swing cylinders (#126) with ports 4A & 4B.

The inset shows restrictor assemblies in ports 4A & 4B, and they appear to be some kind of o-ring sealed fittings.

When I rebuilt this hoe, there were no special fittings, o-rings, or any restrictions in the existing fittings.

The pics below appear to show just standard hose connection fittings.

My questions are these:

Do these fittings appear to be anything besides a standard hose/cylinder connection?

Is it likely that there were washer style restrictors in these fittings at one time that fell out when the hoses where changed or cylinders serviced?

Is it likely that someone removed the restrictors?

Can I just buy a restrictor that will connect between the hose & cylinder?

Thanks in advance!

This requires VERY careful, slow feathering when swinging side to side. I would like to ad restrictors to slow this way down, and was looking at the hose/valve/cylinder layout to decide where to put the restrictors in. The swing cylinders are single acting, so I thought the best location for a restrictor would be where the line connects to the cylinder.

Looking at the diagram, it appears there are supposed to be restrictors at that location.

Drawing shows swing cylinders (#126) with ports 4A & 4B.

The inset shows restrictor assemblies in ports 4A & 4B, and they appear to be some kind of o-ring sealed fittings.

When I rebuilt this hoe, there were no special fittings, o-rings, or any restrictions in the existing fittings.

The pics below appear to show just standard hose connection fittings.

My questions are these:

Do these fittings appear to be anything besides a standard hose/cylinder connection?

Is it likely that there were washer style restrictors in these fittings at one time that fell out when the hoses where changed or cylinders serviced?

Is it likely that someone removed the restrictors?

Can I just buy a restrictor that will connect between the hose & cylinder?

Thanks in advance!