I decided to add an hour meter to keep track of the PTO hours so I can do a better job of maintaining my snowblower. It has a 4 hour interval for chain lubrication, and a 20 hour interval for greasing the drive shaft, and u joints. I already keep a maintenance journal to record all operating hours, but don’t run the PTO the entire time the engine is running so actual PTO hours are always a guess as to actual time running. Adding a switch to the PTO engagement lever will allow me to power the hour meter only while the PTO is running.

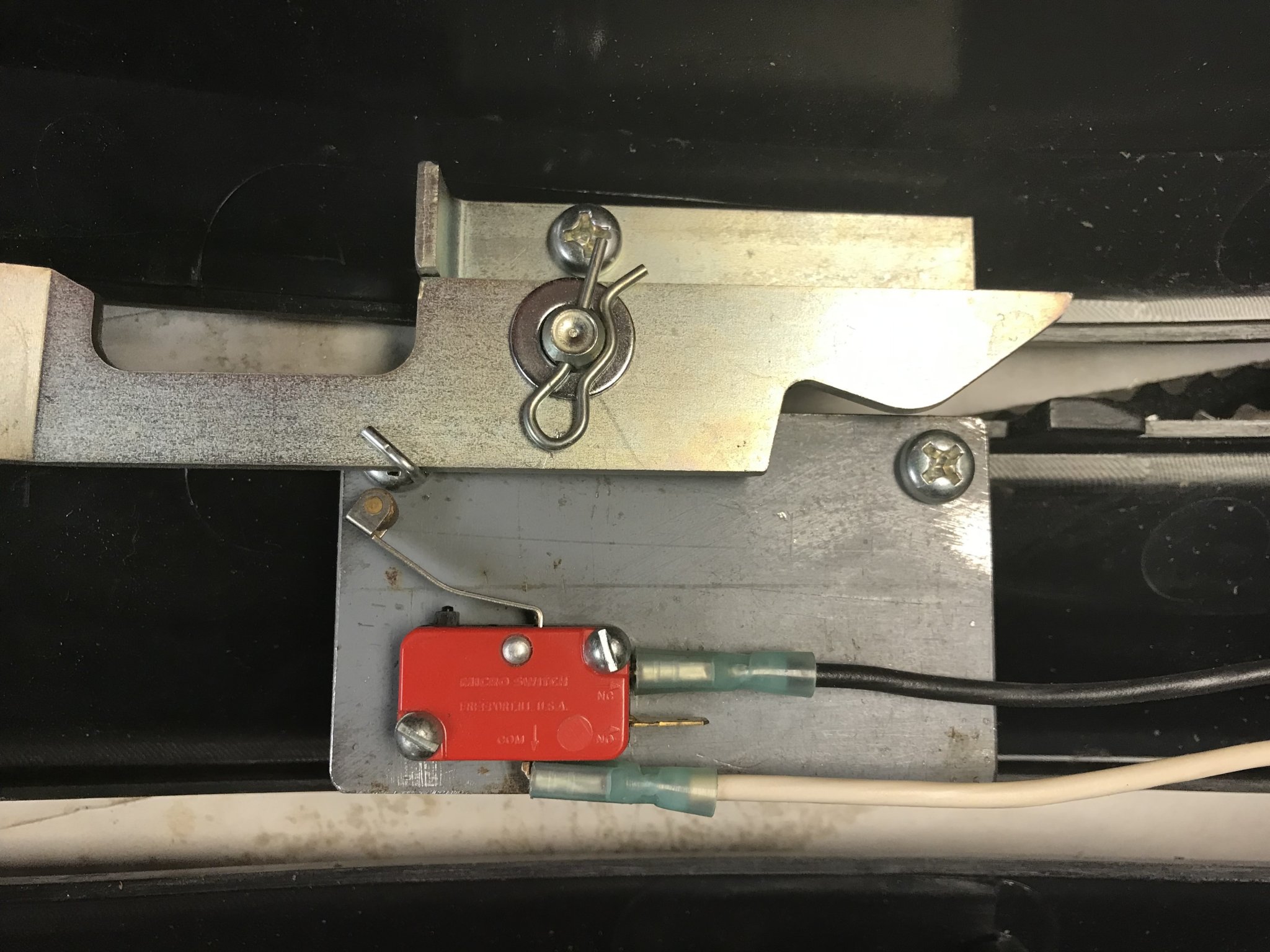

So far it has been a very easy to fashion a mounting bracket to hold the switch, and there is already a 12v aux. source at the rear of the seat area that I can use to power the hour meter. So with a small amount of wiring, and a few terminals, it will be complete. I have a 12v hour meter on order from Amazon, so as soon as I receive it I will install it in the plastic shroud around the levers that control the PTO engagement and transmission speed selector. Here is a picture of my progress so far

So far it has been a very easy to fashion a mounting bracket to hold the switch, and there is already a 12v aux. source at the rear of the seat area that I can use to power the hour meter. So with a small amount of wiring, and a few terminals, it will be complete. I have a 12v hour meter on order from Amazon, so as soon as I receive it I will install it in the plastic shroud around the levers that control the PTO engagement and transmission speed selector. Here is a picture of my progress so far