Like TheOldHokie said, they're basically a sandwich held together with tie rods, with an o-ring in between to prevent external leakage. If you take it apart, there is the o-ring TOH mentioned but also a light spring on the load check in each section.

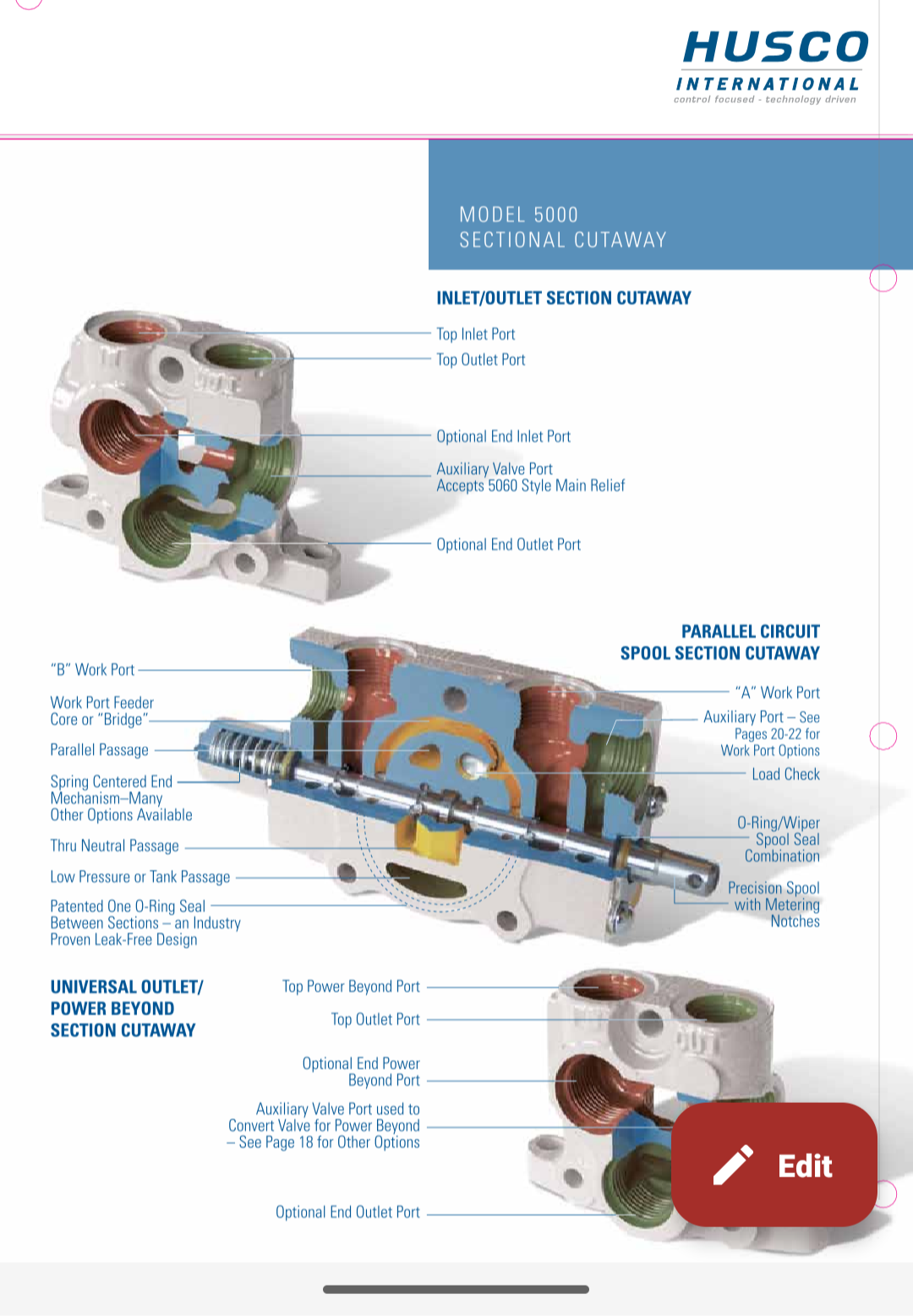

Here's a cutaway showing how the valve is assembled, including a parallel circuit, double-acting section with a spring-centered end mechanism like your swing would have. Your section may have a load relief not shown in this picture.

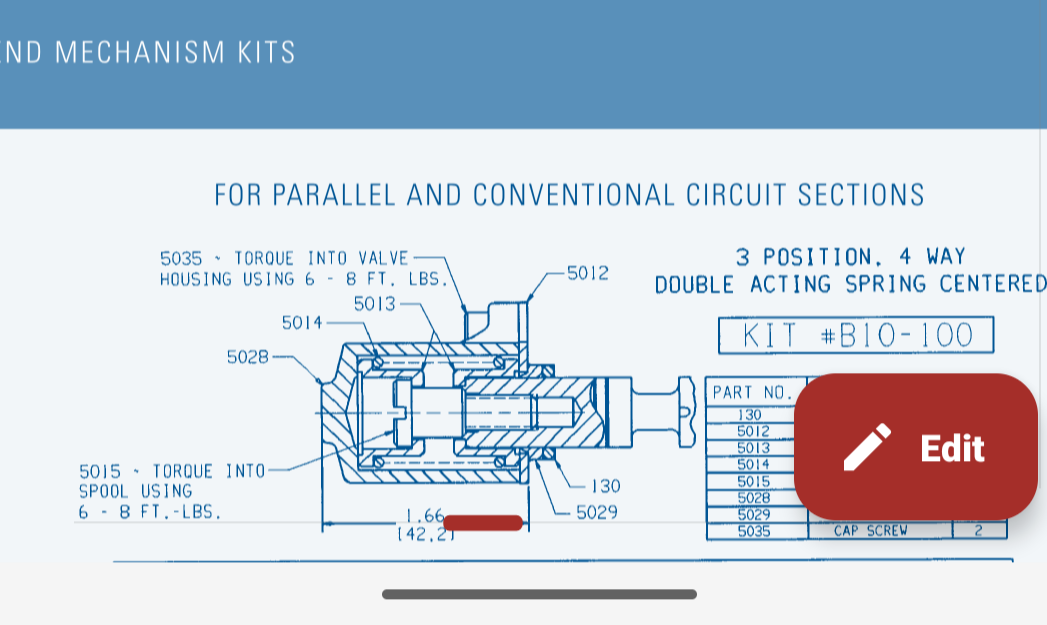

The drawing below shows the parts inside the spring-centered end mechanism which keeps the stick centered when you're not pushing it.

With that all said, here's what I would do:

1 Make sure the joystick linkage is free to move and not hanging up on something. Maybe a cotter pin broke letting a pin slide out and hang up on something?

2 Disconnect the linkage from the spool and try to move the spool both ways. That spring is stiff - I think it takes a 15 to 20 pound force to move without the leverage of the control stick - so you'll have to rig a pry bar to pull and push it.

3 Remove the two screws holding the end mechanism on and slip the cover (5028) off. I think rust in that area is the most likely problem, if the linkage checks out ok. If you can't do this with the valve in place, you'll have to remove it which is no fun, I'm sure. You'll have to remove 14 hoses (marked first!), the linkages, and 4 bolts holding it on. Hopefully, you'll find rust is preventing movement and you can free it up.

If you get to this point and haven't found the problem, the problem must be in the valve itself. You shouldn't need to un-stack the valve up to this point. I personally think an internal problem is less likely since it's full of clean oil. But if you get to that point, report back.

EDIT: your BT600 is not exactly like the pictures posted above. Your Kubota component parts diagram is somewhat different.

Here's a cutaway showing how the valve is assembled, including a parallel circuit, double-acting section with a spring-centered end mechanism like your swing would have. Your section may have a load relief not shown in this picture.

The drawing below shows the parts inside the spring-centered end mechanism which keeps the stick centered when you're not pushing it.

With that all said, here's what I would do:

1 Make sure the joystick linkage is free to move and not hanging up on something. Maybe a cotter pin broke letting a pin slide out and hang up on something?

2 Disconnect the linkage from the spool and try to move the spool both ways. That spring is stiff - I think it takes a 15 to 20 pound force to move without the leverage of the control stick - so you'll have to rig a pry bar to pull and push it.

3 Remove the two screws holding the end mechanism on and slip the cover (5028) off. I think rust in that area is the most likely problem, if the linkage checks out ok. If you can't do this with the valve in place, you'll have to remove it which is no fun, I'm sure. You'll have to remove 14 hoses (marked first!), the linkages, and 4 bolts holding it on. Hopefully, you'll find rust is preventing movement and you can free it up.

If you get to this point and haven't found the problem, the problem must be in the valve itself. You shouldn't need to un-stack the valve up to this point. I personally think an internal problem is less likely since it's full of clean oil. But if you get to that point, report back.

EDIT: your BT600 is not exactly like the pictures posted above. Your Kubota component parts diagram is somewhat different.

Last edited: