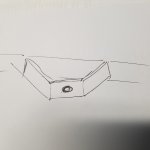

I've got a mini round baler, about 1200 pounds. It's bottom links are too close together to use my QH15. So I want to figure out how to make the bottom links wider. I was thinking getting longer pins, but that might put a lot of torque on the pins? Then I was thinking of getting a good welder to cut the bottom links off the baler and weld them back on to be wider.

Any thoughts / suggestions? Thanks.

Any thoughts / suggestions? Thanks.