I don't know how many hours on the engine. No hour meter on the tractor and I know the engine has been rebuilt at least once.My bet is a bad injector. How many hours on the engine?

You might consider pulling the injectors and checking the spray pattern.

White smoke at high RPM

- Thread starter uler3161

- Start date

Assuming the worst case and that I'd need to spend a bit of money, I was wondering if I could just put a different engine in it and gain a little extra power as well. I'm actually pushing it a bit running the tiller, so a little more power would be nice.

What I've read on here is that it's too much of a hassle, but what would be so hard about putting an engine out of a something like a B7100 in it? They look a lot alike, but do they have a physically bigger engine compartment or something?

What I've read on here is that it's too much of a hassle, but what would be so hard about putting an engine out of a something like a B7100 in it? They look a lot alike, but do they have a physically bigger engine compartment or something?

Wild & Free's advice is 100% correct. I would suggest slowing down a bit. It does run, and you might be surprised with a relatively easy fix.

If I were you, I'd pull all of the injectors and take them to an injection shop for testing/rebuilding. It could be that you have a bad injector that is causing the smoke.

Regarding the "hydrolock" situation Orange wrote about, he mentioned it occurred "it was after maintenance that I tried to start it a couple times and it wouldn't."

This makes me a bit nervous because it almost sounds like a valve adjustment might have been done and one of the valves was way too tight causing it to kiss a piston. Not sure how else any liquid would get into the cylinder during maintenance. The only other option would ether as Wild mentioned... If a valve is/was way too tight, it could have bent, or cracked either a piston, liner or the head and could result in a coolant leak.

If either or these situations were due to too much fuel running into the cylinder from a bad injector, you might just get lucky with a rebuild on the injector(s) and have it/them run perfectly.

I'd also second the compression test while you're at it. If either engine has been rebuilt, it may be just fine and not need anything.

Regarding the one that hydrolocked, since you were relatively easy on it, you might just get lucky and escape without any damage.

Just my $.02,

Steve

If I were you, I'd pull all of the injectors and take them to an injection shop for testing/rebuilding. It could be that you have a bad injector that is causing the smoke.

Regarding the "hydrolock" situation Orange wrote about, he mentioned it occurred "it was after maintenance that I tried to start it a couple times and it wouldn't."

This makes me a bit nervous because it almost sounds like a valve adjustment might have been done and one of the valves was way too tight causing it to kiss a piston. Not sure how else any liquid would get into the cylinder during maintenance. The only other option would ether as Wild mentioned... If a valve is/was way too tight, it could have bent, or cracked either a piston, liner or the head and could result in a coolant leak.

If either or these situations were due to too much fuel running into the cylinder from a bad injector, you might just get lucky with a rebuild on the injector(s) and have it/them run perfectly.

I'd also second the compression test while you're at it. If either engine has been rebuilt, it may be just fine and not need anything.

Regarding the one that hydrolocked, since you were relatively easy on it, you might just get lucky and escape without any damage.

Just my $.02,

Steve

Last edited:

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

Thanks again, for those who didn't see my other post it happened because I replaced the radiator shroud, drained some coolant and removed the radiator side of the top radiator hose.... Instead of draining all the coolant I just removed what I thought was enough, where I screwed up is I didn't have a rag to stuff in the end of the hoses I just stuck the radiator hose in the intake hose... Well moving things I must have gotten some coolant in the intake hose.. Service was oil, filters, UDT, and HUD screen. NOTHING was adjusted internally. I just made the dumb mistake of putting the radiator hose inside the intake hose to keep from dropping anything in it.Wild & Free's advice is 100% correct. I would suggest slowing down a bit. It does run, and you might be surprised with a relatively easy fix.

If I were you, I'd pull all of the injectors and take them to an injection shop for testing/rebuilding. It could be that you have a bad injector that is causing the smoke.

Regarding the "hydrolock" situation Orange wrote about, he mentioned it occurred "it was after maintenance that I tried to start it a couple times and it wouldn't."

This makes me a bit nervous because it almost sounds like a valve adjustment might have been done and one of the valves was way too tight causing it to kiss a piston. Not sure how else any liquid would get into the cylinder during maintenance. The only other option would ether as Wild mentioned... If a valve is/was way too tight, it could have bent, or cracked either a piston, liner or the head and could result in a coolant leak.

If either or these situations were due to too much fuel running into the cylinder from a bad injector, you might just get lucky with a rebuild on the injector(s) and have it/them run perfectly.

I'd also second the compression test while you're at it. If either engine has been rebuilt, it may be just fine and not need anything.

Regarding the one that hydrolocked, since you were relatively easy on it, you might just get lucky and escape without any damage.

Just my $.02,

Steve

The question is YES I hydro locked it but what gave? What's the first thing you Gus would suspect? Lifted head? Gasket? Injector? Cracked head? Where would I begin.

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

If this helps see the intake hose connects to the filter housing (part of shroud) and the top radiator hose goes through the shroud. So both have to come off. I took the tops of each off and stuffed them inside each other for the duration of the repair.. This is when an unknown amount of coolant entered the intake of engine.

Attachments

-

62.3 KB Views: 413

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

Thanks again, for those who didn't see my other post it happened because I replaced the radiator shroud, drained some coolant and removed the radiator side of the top radiator hose.... Instead of draining all the coolant I just removed what I thought was enough, where I screwed up is I didn't have a rag to stuff in the end of the hoses I just stuck the radiator hose in the intake hose... Well moving things I must have gotten some coolant in the intake hose.. Service was oil, filters, UDT, and HUD screen. NOTHING was adjusted internally. I just made the dumb mistake of putting the radiator hose inside the intake hose to keep from dropping anything in it.

The question is YES I hydro locked it but what gave? What's the first thing you Gus would suspect? Lifted head? Gasket? Injector? Cracked head? Where would I begin.

I went back to your own thread and posted there as I missed the details leading up to your issues.

If this helps see the intake hose connects to the filter housing (part of shroud) and the top radiator hose goes through the shroud. So both have to come off. I took the tops of each off and stuffed them inside each other for the duration of the repair.. This is when an unknown amount of coolant entered the intake of engine.

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

Thanks again. Ill keep posting here because the OP said he was learning too, and were on a roll so why not.

So you think it's ok to run it for a while? I have about 45 minutes on it. I thought about letting it run at 2900rpm (right at the threshold of smoke and slowly increase over an hour or Two but was curious if that was a good idea. Also it does smoke pretty bad at all rpm when the engine is room temp.

So you think it's ok to run it for a while? I have about 45 minutes on it. I thought about letting it run at 2900rpm (right at the threshold of smoke and slowly increase over an hour or Two but was curious if that was a good idea. Also it does smoke pretty bad at all rpm when the engine is room temp.

Hi,Thanks again. Ill keep posting here because the OP said he was learning too, and were on a roll so why not.

So you think it's ok to run it for a while? I have about 45 minutes on it. I thought about letting it run at 2900rpm (right at the threshold of smoke and slowly increase over an hour or Two but was curious if that was a good idea. Also it does smoke pretty bad at all rpm when the engine is room temp.

Just going put in my 2 cents

A motor gets hydrauliced because the piston comes up on compression stroke with both valves closed and encounters an uncompressible liquid.

Just the inertia of the spinning flywheel and the power of the starter (with all of its gear multiplication) is enough to do damage

The valves are closed so they can't be bent and the part that usually fails is the bending of the connecting rod.

If you want to gamble that the bent connecting rod will stay together than you can run the engine and take your chances or you can do the safe thing and pull the motor apart.

With a hydrauliced engine the damage could be a bent rod, collapsed piston, bent wrist pin, cracked main bearing bulkheads and the list goes on and on...

I think that you should do the safe thing and not run the engine again and disassemble it to check for damaged parts...

Even if it is something major to repair it would still be cheaper than replacing a blown engine....

Like they said in the old Fram filter commercial "Pay me now or pay me later"

It all depends on the amount you pay

Good luck with whatever you decide,

Bob

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

Reply in red within the quote above.Hi,

Just going put in my 2 cents

A motor gets hydrauliced because the piston comes up on compression stroke with both valves closed and encounters an uncompressible liquid.

Just the inertia of the spinning flywheel and the power of the starter (with all of its gear multiplication) is enough to do damage

The valves are closed so they can't be bent and the part that usually fails is the bending of the connecting rod.

If the piston is coming up on the exhaust stroke it bends valve stems or bends push tubes as the piston is coming up and compressing the liquid the valve is trying to open against it as well.

If you want to gamble that the bent connecting rod will stay together than you can run the engine and take your chances or you can do the safe thing and pull the motor apart.

If he has run it for 45 minutes already it it most likely no major issues plus if it was a bent rod it would be running like crap and vibrating a shaking like heck.

With a hydrauliced engine the damage could be a bent rod, collapsed piston, bent wrist pin, cracked main bearing bulkheads and the list goes on and on...

I think that you should do the safe thing and not run the engine again and disassemble it to check for damaged parts...

A compression check will tell him a ton along with an injector test.

Even if it is something major to repair it would still be cheaper than replacing a blown engine....

Not always, a lot of times it is cheaper to replace and engine versus pay shop labor to verhaul unless one does his own work.

Like they said in the old Fram filter commercial "Pay me now or pay me later"

Running Fram filters will cause you to pay in the long run anyhow

It all depends on the amount you pay

Good luck with whatever you decide,

Bob

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

I do thank you all for your reply, I understand both points, but am buying the compression check. If I have 2 pistons At 450psi and one at 400 at least I know I am in fact loosing compression and even if it is a rod the head has to come off anyway. So ill start with the head and hope for a gasket or valve. At that time I can use a depth gage or indicator to check all 3 for top dead center. If one has a shorter stroke that rules out head, rings ect and points to bottom end.

I found a pretty good DIY home made pop tester made from a bottle jack I may try to see what each nozzle sprays at.

Even before that I may pull the injectors, turn the hard lines and reinstall, crank engine (with injectors hanging out) and look at the spray pattern. Thanks again guys for the info

I found a pretty good DIY home made pop tester made from a bottle jack I may try to see what each nozzle sprays at.

Even before that I may pull the injectors, turn the hard lines and reinstall, crank engine (with injectors hanging out) and look at the spray pattern. Thanks again guys for the info

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

Do not I repeat do not try and do injector testing yourself unless you are replacing them and you know exactly what you are looking for, modern injectors have very tight tolerances and even single micron particles will cause damage if you do not have certified clean testing fluid and equipment you will probably do more harm than good, an injection shop could check 3 injectors for around a hundred bucks a bit more if all they need is pressure adjustment.

Check the valve adjustment as well to see if it has any bent push rods or valves.

Check the valve adjustment as well to see if it has any bent push rods or valves.

Not to get into a p-----g contest.........

But

I don't have the specific cam timing info for the LZ600 engine

In a 4 cycle engine the piston is coming up towards the open exhaust valve and closed intake valve on the exhaust stroke.....the piston is chasing the exhaust valve back onto its seat.

Just before TDC the intake starts to open while the exhaust valve is still open and this is called overlap....The exhaust valve doesn't close until after TDC

As the piston completes the exhaust stroke at TDC with the intake and exhaust valves still not seated the piston starts down the bore with the intake valve chasing the piston....

When the piston gets to BDC the intake is almost closed (the intake doesn't close until after BDC.

The piston now starts up towards the head on the compression stroke, against the closed intake & exhaust valves, fuel is injected before TDC, ignited and then the piston starts it downward travel on the power stroke..

That is the 4 stroke engine cycle....Intake, Compression, Power, Exhaust

Both valves are closed only on the compression stroke....

I race cars and build engines and have for 50 years...

Camshaft timing is a great way to make horsepower...

Just saying...

Bob

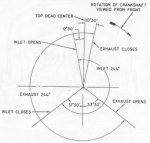

The attachment shows typical valve timing

But

I don't have the specific cam timing info for the LZ600 engine

In a 4 cycle engine the piston is coming up towards the open exhaust valve and closed intake valve on the exhaust stroke.....the piston is chasing the exhaust valve back onto its seat.

Just before TDC the intake starts to open while the exhaust valve is still open and this is called overlap....The exhaust valve doesn't close until after TDC

As the piston completes the exhaust stroke at TDC with the intake and exhaust valves still not seated the piston starts down the bore with the intake valve chasing the piston....

When the piston gets to BDC the intake is almost closed (the intake doesn't close until after BDC.

The piston now starts up towards the head on the compression stroke, against the closed intake & exhaust valves, fuel is injected before TDC, ignited and then the piston starts it downward travel on the power stroke..

That is the 4 stroke engine cycle....Intake, Compression, Power, Exhaust

Both valves are closed only on the compression stroke....

I race cars and build engines and have for 50 years...

Camshaft timing is a great way to make horsepower...

Just saying...

Bob

The attachment shows typical valve timing

Attachments

-

13.3 KB Views: 1,485

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

Bob you are 100% correct.................if it only had air in the cylinder, you must have forgot we are talking about a hydro locked engine.

Fill the top of a cylinder with a noncompressable liquid it is no different than adding height to the piston, that solid mass is coming up and hitting an exhaust valve that is still slightly open and it hits the valve like a hammer, water is solid, imagine your hand hitting water as hard as you can. Water does not exit like air does. Depending on how much water is on top of the piston you can't squeeze water out of a few cc opening when you have several Cubic inches of water hitting it like a brick wall. This is how valves and push rods get bent, Having been a Diesel tech for 20 years I have seen it many many times.

Fill the top of a cylinder with a noncompressable liquid it is no different than adding height to the piston, that solid mass is coming up and hitting an exhaust valve that is still slightly open and it hits the valve like a hammer, water is solid, imagine your hand hitting water as hard as you can. Water does not exit like air does. Depending on how much water is on top of the piston you can't squeeze water out of a few cc opening when you have several Cubic inches of water hitting it like a brick wall. This is how valves and push rods get bent, Having been a Diesel tech for 20 years I have seen it many many times.

Last edited:

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

Bob I agree. But not sure what your pointing out. I just want to know what went wrong. Sounds like folks think my injector/injectors went bad (to this moment I can't figure out why... But I'm taking everything into account. I was honestly thinking it was the head gasket and someone would say yep... But that kubota is built funny and this.... (Enter Internet finding here) is why your not getting water in oil, oil in water or spewing coolant.

I'm 99% sure what's being pumped out the exhaust is raw diesel due to smell and appearance. I don't think there is coolant in it. And don't feel that it's burning crank case oil (again because of smell)

I'm 99% sure what's being pumped out the exhaust is raw diesel due to smell and appearance. I don't think there is coolant in it. And don't feel that it's burning crank case oil (again because of smell)

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

If my logic is correct I'm trying to determine why I have unburnt (under compressed diesel) is it due to head gasket, too many cc (bent rod) not enough compression (rings) or leaking/poor injector pattern. OR is it something completely different.

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

When it is warmed up do you have a bit more blowby coming from the crank case breather?

This is why a valve adjustment check would be first if a valve stem or valve head is bent or it cracked a valve seat it will effect adjustment and could cause low compression as well. Second pull injectors and measure compression and if that passes then have injectors checked.

This is why a valve adjustment check would be first if a valve stem or valve head is bent or it cracked a valve seat it will effect adjustment and could cause low compression as well. Second pull injectors and measure compression and if that passes then have injectors checked.

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

Ok wild, went Down today to check it out and scratch my brain a little bit more, before starting it I checked oil and radiator as well as coolant reservoir for signs of water or oil whether or not supposed to be I did not see any signs of either. Even though its almost 80 degrees out I allowed the glow plugs to heat for about 10 seconds and cranked over. There is now bluish smoke for 15-20 seconds that quickly dissipates UNLESS I have it over 3000rpm then there is still quite a bit of smoke. All a bluish tinge now. Smell is odd but not exactly that of typical motor oil. This is synthetic and BRAND new so maybe that's why.

Any who it looks that all the residual coolant that may have been in the intake worked itself out/water evaporated. What should I be thinking now? Head gasket?

Any who it looks that all the residual coolant that may have been in the intake worked itself out/water evaporated. What should I be thinking now? Head gasket?

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

To answer your question, no there isn't excessive blowby... Really none at all. And all fluids were still normal before and after the last run (15 minutes or so)

Wild and Free

New member

Equipment

B2150 HSD w/Case L340 fel 68" quicktach bkt, 60" jinma snowblower, box scraper

Doesn't take much to pop the valve cover off and check valve lash and look it over really close to see if a valve guide seal is out of place, "I don't know if it has guide seals or what type" but look inside the valve springs if you can and see if any thing looks out of place with one or two of them.

I assume it starts and runs perfect yet and no obvious vibrations or slight miss ect ?

I assume it starts and runs perfect yet and no obvious vibrations or slight miss ect ?

Orange2009

New member

Equipment

Kubota BX25, BH, FEL, 60" belly mower, 48" tiller, Middle buster, Stripe kit etc

It does have a slight pop or miss when cold and first started. That's when there is smoke. Once it runs for 30 seconds or so and the pre 3000rpm smoke stops it runs great. At 3000-full throttle it does have a very lightly detectable miss here and there. Vibration seems to be no different then when the unit was brand new. I just really hate dealers workin on anything of mine. I rather fix it myself if I can. Ill try to check the valve lash this evening. I I can get out there.. How do I confirm TDC on this engine while in frame? I know the tolerance is posted on the valve cover.Doesn't take much to pop the valve cover off and check valve lash and look it over really close to see if a valve guide seal is out of place, "I don't know if it has guide seals or what type" but look inside the valve springs if you can and see if any thing looks out of place with one or two of them.

I assume it starts and runs perfect yet and no obvious vibrations or slight miss ect ?