You got a link for the box, or did you build it? I have 4 payments left on my LX and want something a little larger and a lot tougher than the plastic box. I put an ammo can on each side of the ROPS bar using existing holes and could add two more if I make a couple more brackets, but having that box that close is the best storage for pins, clevises, bushings, etc. I keep a few basic tools in the ammo box on the left and a 20’ 5/16 chain on the right. Quite by accident I found that the inertia of the chain coming out of the ammo box keeps it from hitting the fender. It actually shoots out past the oversized R14T. Who knew?I removed the loader from my new L3302 for the first time then disked the garden spot for the fourth time hoping it will dry out( love that FWA ). Then I dropped the disk and put the quick hitch on (heavy sucker) and hooked up my 5 ft. light duty rotary cutter. It was 92 with 60% humidity this afternoon so I stayed in and then went out around 7 and cut grass for an hour or so. I now have 15 hours on the tractor and should be getting a regen soon. I've been running 2500(PTO) to 2700 RPM (disking). I replaced the plastic toolbox with a 16"x4"x4" steel one Last Friday. Mounted it right where the plastic one was. I've got to modify my tiller,hipper,box blade, and disk to work with my quick hitch. I have the forked top link adapter and was successful connecting the rotary mower. The rest of the stuff needs the A frame top link braces relocated to allow the hook to be used so I can just pick up and go. I love this tractor.

What did you do to or on your Kubota today?

- Thread starter gurn

- Start date

And if IRC these are along your property line and not for another purpose ??

gg

Siesta Sundance

Well-known member

Lifetime Member

Equipment

L305DT, MX 5200, SVL 75-2, (Sold M7060))

You are one tree planting dude....And if IRC these are along your property line and not for another purpose ??gg

Once you get all these growing for privacy, you gonna open a nudist camp or something? j/k,

My 81 year old neighbor had some trees removed from his back yard. The tree service had to move his car hauler trailer so it wouldn't be in the way while dropping the trees. They didn't put the trailer back when they finished.

He asked me if I could use my tractor to put the trailer back where it was. It took me 5 minutes.

After thanking me he told me at 81 even 5 minute jobs are exhausting.

He asked me if I could use my tractor to put the trailer back where it was. It took me 5 minutes.

After thanking me he told me at 81 even 5 minute jobs are exhausting.

Have any of you made a cylinder safety stop for your loader? I'm looking for fabricate my own. I was just wondering because it will be a lot easier and a safer to service the tractor. 10 more hours until first oil change! Gonna replace the filters too, might as well change the fuel filter while I'm at it. It doesn't look bad at all but can't hurt. The air filter needs to be changed as well. Gonna be a pricey day at the dealership getting the stuff

Hi S-G-R, I'm in PEI too and have a neighbor looking for spruce trees for a hedge row at a cottage property on the north shore. Those trees look good. Would you mind sharing where your purchased them. Thank youPlanted another 36 trees

Orange man

Active member

Equipment

Kubota L2502 LA526 loader , woods prd6000 mower, Land pride RB 1672

I have

I have just removed the loader when doing service, only takes a few minutes, and better access to everything.Have any of you made a cylinder safety stop for your loader? I'm looking for fabricate my own. I was just wondering because it will be a lot easier and a safer to service the tractor. 10 more hours until first oil change! Gonna replace the filters too, might as well change the fuel filter while I'm at it. It doesn't look bad at all but can't hurt. The air filter needs to be changed as well. Gonna be a pricey day at the dealership getting the stuff

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

Same.I have

I have just removed the loader when doing service, only takes a few minutes, and better access to everything.

I haven't tried taking it off. A little scared to be honest because I'm worried I'll screw it up haha and never get it back on. I watched videos and people make it look easy but nothing ever goes easy for meI have

I have just removed the loader when doing service, only takes a few minutes, and better access to everything.

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

Only “trick” is take it off on a flat place big enough to be flat for both tractor and loader, and solid enough the loader stands won’t sink into the supporting surface. Flat concrete/pavement is ideal but not necessary.I haven't tried taking it off. A little scared to be honest because I'm worried I'll screw it up haha and never get it back on. I watched videos and people make it look easy but nothing ever goes easy for me

First off/on took me 45 minutes. I knew I had to take it off for some of the routine mowing I bought it to do, so it wasn’t optional for me. Now it’s less than 5 minutes off, same putting back on.

If I didn’t have a flat spot, I’d get some angle iron and make some cylinder blocks or buy them.

I have a flat driveway with plenty of room. I feel confident I can get it off easy but aligning it back on to get the pins to slide into the frame will be tough I think.Only “trick” is take it off on a flat place big enough to be flat for both tractor and loader, and solid enough the loader stands won’t sink into the supporting surface. Flat concrete/pavement is ideal but not necessary.

First off/on took me 45 minutes. I knew I had to take it off for some of the routine mowing I bought it to do, so it wasn’t optional for me. Now it’s less than 5 minutes off, same putting back on.

If I didn’t have a flat spot, I’d get some angle iron and make some cylinder blocks or buy them.

The Quick Hitch has been a nice add to my 3302. It works great with my Land Pride implements but I have had issues with another implement.I'm getting ready to order an L3302 or L3902 and am putting together my purchase list and "wish list". Not sure which list the quick hitch should go on. Sounds like a useful addition but not sure if it is justified at this point. I will mostly be switching between a rotary cutter and box blade on the rear PTO.

Orange man

Active member

Equipment

Kubota L2502 LA526 loader , woods prd6000 mower, Land pride RB 1672

The pins self align when you tilt the loader back onto the brackets.I have a flat driveway with plenty of room. I feel confident I can get it off easy but aligning it back on to get the pins to slide into the frame will be tough I think.

Basically yes. Just unplug and remove the factory cigarette lighter (unscrew the metal retaining sleeve), open up the hole a bit to 1-1/8", install the USB outlet, tighten the retaining nut and reconnect the spade lugs. Blue Sea Systems products are designed for boats so need to be rugged and weatherproof. There's no illumination to fail, just good quality plastics, a simple appearance and some clever internals. This USB outlet will work well on an open station or cabbed tractor.Nice! Was it plug and play?

This is my third Kubota with a loader. I've had the loaders off and on hundreds of times because I don't have the loader on unless I'm using it. There were two times in 23 years that were a genuine struggle. Both were due to stupidity.Only “trick” is take it off on a flat place big enough to be flat for both tractor and loader, and solid enough the loader stands won’t sink into the supporting surface. Flat concrete/pavement is ideal but not necessary.

First off/on took me 45 minutes. I knew I had to take it off for some of the routine mowing I bought it to do, so it wasn’t optional for me. Now it’s less than 5 minutes off, same putting back on.

If I didn’t have a flat spot, I’d get some angle iron and make some cylinder blocks or buy them.

Once was when I wasn't paying attention and didn't put the right side pin in while re-mounting the loader. I hopped out while the tractor was raised on the bucket edge and rear tires. Sometimes that's when I put the support arms in the carry position. That's what I did and only realized my error when I tried to lift the bucket. The right side of the loader frame popped out of its receiver. The hydraulics were no help. Fortunately it was in the shed, so I used a small lever chain hoist to get it into position.

The other time was when I was in too much of a hurry to drive to a better (more level) spot to drop the loader. It came off without a hassle, but it was very difficult to reinstall. Fortunately #2 Son was visiting. Various pieces of wood, a digging iron for lifting, and a second pair of hands to place the cribbing and we managed to get it back on.

For some reason I thought the hydraulics on the loader would drift but the fluid has nowhere to go as it can't go back into the tank, so it should stay where you put it right?This is my third Kubota with a loader. I've had the loaders off and on hundreds of times because I don't have the loader on unless I'm using it. There were two times in 23 years that were a genuine struggle. Both were due to stupidity.

Once was when I wasn't paying attention and didn't put the right side pin in while re-mounting the loader. I hopped out while the tractor was raised on the bucket edge and rear tires. Sometimes that's when I put the support arms in the carry position. That's what I did and only realized my error when I tried to lift the bucket. The right side of the loader frame popped out of its receiver. The hydraulics were no help. Fortunately it was in the shed, so I used a small lever chain hoist to get it into position.

The other time was when I was in too much of a hurry to drive to a better (more level) spot to drop the loader. It came off without a hassle, but it was very difficult to reinstall. Fortunately #2 Son was visiting. Various pieces of wood, a digging iron for lifting, and a second pair of hands to place the cribbing and we managed to get it back on.

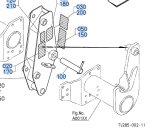

The pin I spoke of was part #100 below. The hydraulics of the lift cylinders are connected to each other. Unless both are physically connected to their "load" the connected cylinder won't move the load and the hydraulic flow diverts to the loose one and it will just go back and forth in the air.

When I reinstall the loader, I usually stop short, connect the hoses, then drive in closer. At that point I pull the stick as you would to raise the loader. The two frame sides rotate toward the tractor to meet the two main frame pieces on the tractor. Frequently the movements of the two cylinders are not exactly in sync. After the first one contacts the main frame, the other moves till it also touches its main frame.

Then dumping the bucket drops the frame sides into the main frame. A little more rotation or a little down pressure on the loader lifts the front wheels. At that point BOTH! #100 pins go in (not just ONE as I did) and the two stands can be raised and pinned. Next the loader is lifted and off you go.

in my case with the right #100 pin not installed, the right side of the frame jumped out. With the stands already in their stored position, the hydraulics couldn't help me. The loader was sitting too low to allow the stands to be rotated into their lowered position.

When I reinstall the loader, I usually stop short, connect the hoses, then drive in closer. At that point I pull the stick as you would to raise the loader. The two frame sides rotate toward the tractor to meet the two main frame pieces on the tractor. Frequently the movements of the two cylinders are not exactly in sync. After the first one contacts the main frame, the other moves till it also touches its main frame.

Then dumping the bucket drops the frame sides into the main frame. A little more rotation or a little down pressure on the loader lifts the front wheels. At that point BOTH! #100 pins go in (not just ONE as I did) and the two stands can be raised and pinned. Next the loader is lifted and off you go.

in my case with the right #100 pin not installed, the right side of the frame jumped out. With the stands already in their stored position, the hydraulics couldn't help me. The loader was sitting too low to allow the stands to be rotated into their lowered position.

Attachments

-

92.6 KB Views: 61

So with the loader sitting in the frame cradle but yet pinned in is strong enough to lift the tractor? It wouldn't bend the support arms?The pin I spoke of was part #100 below. The hydraulics of the lift cylinders are connected to each other. Unless both are physically connected to their "load" the connected cylinder won't move the load and the hydraulic flow diverts to the loose one and it will just go back and forth in the air.

When I reinstall the loader, I usually stop short, connect the hoses, then drive in closer. At that point I pull the stick as you would to raise the loader. The two frame sides rotate toward the tractor to meet the two main frame pieces on the tractor. Frequently the movements of the two cylinders are not exactly in sync. After the first one contacts the main frame, the other moves till it also touches its main frame.

Then dumping the bucket drops the frame sides into the main frame. A little more rotation or a little down pressure on the loader lifts the front wheels. At that point BOTH! #100 pins go in (not just ONE as I did) and the two stands can be raised and pinned. Next the loader is lifted and off you go.

in my case with the right #100 pin not installed, the right side of the frame jumped out. With the stands already in their stored position, the hydraulics couldn't help me. The loader was sitting too low to allow the stands to be rotated into their lowered position.

You are correct. The support arms would pretzel in a nanosec under the weight of the tractor.So with the loader sitting in the frame cradle but yet pinned in is strong enough to lift the tractor? It wouldn't bend the support arms?

The weight is on the bucket's cutting edge and the tractor's rear tires. The interface of the loader and frame has tension on it forcing them together. At that time pins are easily slipped in or out.

I'll have to give it a try at some point, probably be good to learn how to do it. I'm just trying to get the movements in my head to do it correctly and not mess up anything.You are correct. The support arms would pretzel in a nanosec under the weight of the tractor.

The weight is on the bucket's cutting edge and the tractor's rear tires. The interface of the loader and frame has tension on it forcing them together. At that time pins are easily slipped in or out.