I decided to add a 3rd function kit to the tractor for an upcoming grapple addition. Since humans install them at the dealership, I figured I should be able to do the same in my shop and save a few dollars. Plus, with most everything shut down it provides something to do and a reason to get educated on the tractor’s hydraulic system. After some looking and thinking, the B2650 kit from Summit Hydraulics was ordered.

Having the BH77 backhoe might also require some adjustments/alterations to be accounted for. At the very least it would be an expensive learning experience. More realistically, I figured it wouldn’t be that hard, I could learn something, and might even save a couple of dollars. The best part would be having done the work…..it’d be easier to trouble shoot down the road knowing how and where the components are and how they function together.

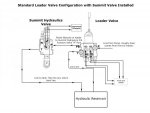

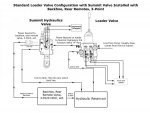

A few people had recently expressed interest in this kit and adding a 3rd function themselves. So, I decided to take some pics hoping it may might help someone in their own decision-making process. Studying the WSM beforehand helped to understand the hydraulic system layout and confirm where the power beyond port was and what needed to be done to cut into the hydraulic system.

Looking at individual component prices it appears that one can’t beat the kit prices offered. Those individual prices start to add up quickly! Thus the “kit” arrived and there was no turning back.

I need to sort and resize some pics and will soon start posting the progress.

Having the BH77 backhoe might also require some adjustments/alterations to be accounted for. At the very least it would be an expensive learning experience. More realistically, I figured it wouldn’t be that hard, I could learn something, and might even save a couple of dollars. The best part would be having done the work…..it’d be easier to trouble shoot down the road knowing how and where the components are and how they function together.

A few people had recently expressed interest in this kit and adding a 3rd function themselves. So, I decided to take some pics hoping it may might help someone in their own decision-making process. Studying the WSM beforehand helped to understand the hydraulic system layout and confirm where the power beyond port was and what needed to be done to cut into the hydraulic system.

Looking at individual component prices it appears that one can’t beat the kit prices offered. Those individual prices start to add up quickly! Thus the “kit” arrived and there was no turning back.

I need to sort and resize some pics and will soon start posting the progress.