No ... but that sounds really cool. It sounds like it would make a really good 30'x40' shop/barn. I'd love to see some photo of such a structure.Have you considered the barns where they set two containers down and put a roof spanning the distance between the two containers?

Steel pole barn, gravel driveway and 40' shipping container

- Thread starter McMXi

- Start date

RK's idea is a good one too! "Clear Span" makes a nice product, as do others. Here's a link to their offerings:No ... but that sounds really cool. It sounds like it would make a really good 30'x40' shop/barn. I'd love to see some photo of such a structure.

HD Container Building | ClearSpan

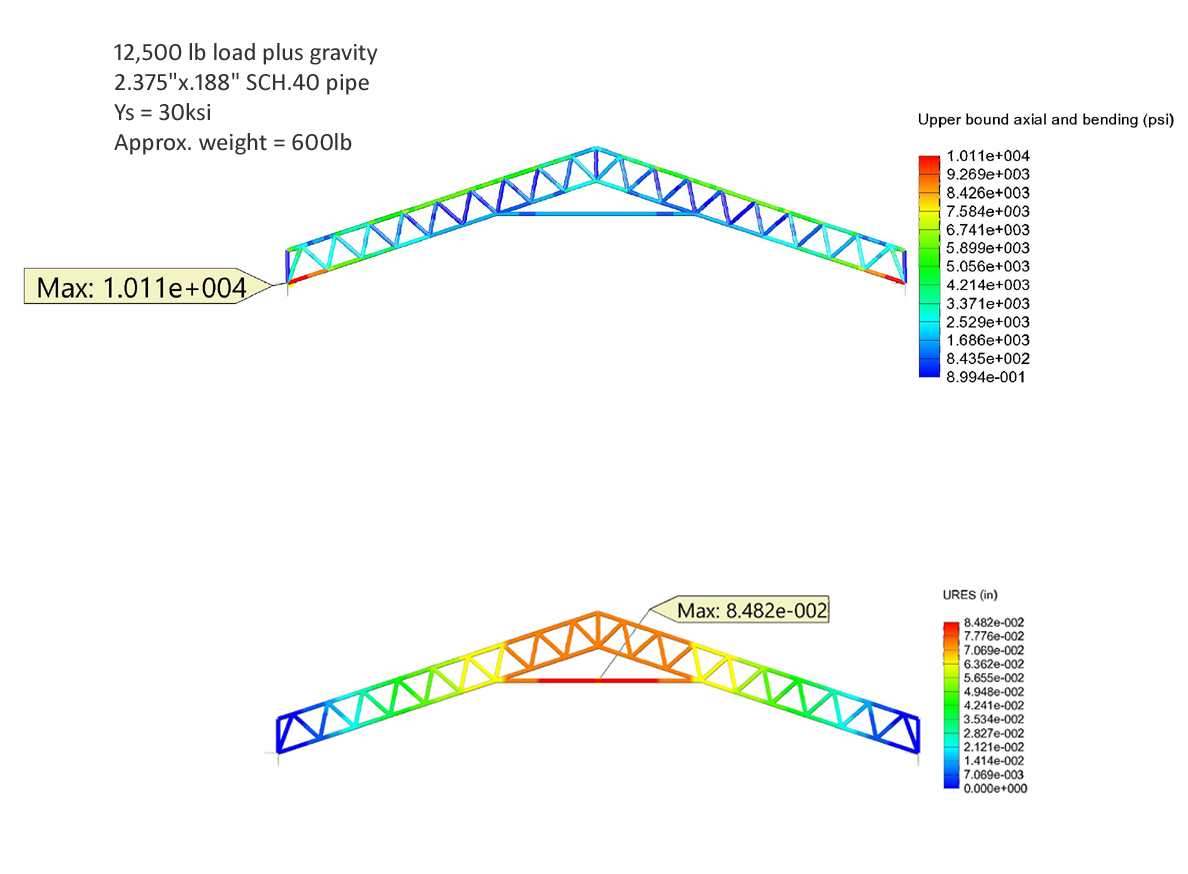

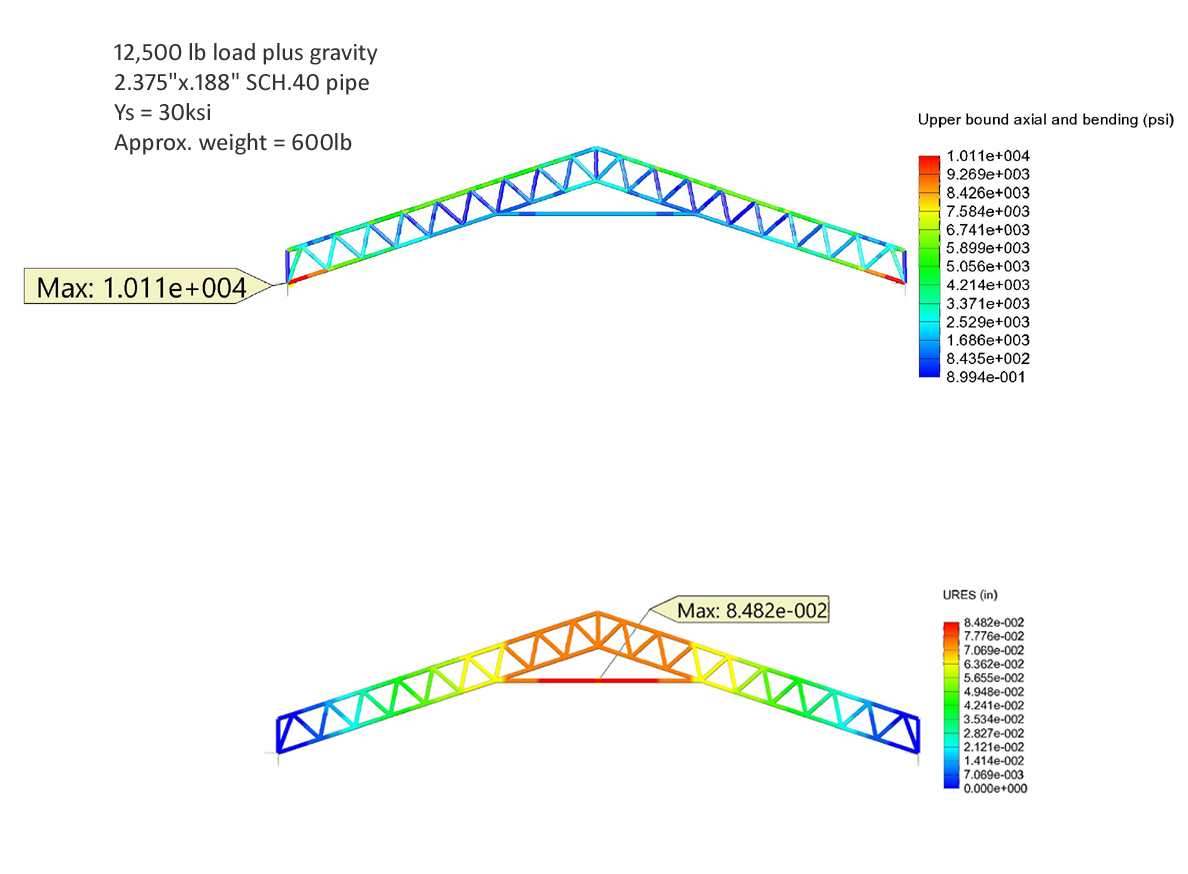

I think there's little doubt that the cheapest trusses in terms of materials would be one made from reclaimed 2-3/8" pipe which costs out at $160 per truss (materials only). Iv'e modeled a few truss designs using pipe or angle and the pipe is more than strong enough, too strong in many ways with a factor of safety of around 3. Galvanized Sch.40 fencing pipe has a yield strength of 30ksi for the lower grade and 50ksi for the higher grade. I need to find out a couple of things about the reclaimed pipe such as confirming the type of steel, the wall thickness, whether or not there's a welded seam, and the likelihood of severe corrosion inside the pipe that I can't see.

Pipe does present some problems though. It would require a lot of coping, and it's not as user friendly when it comes to mounting steel plates for purlins (if I use wood) and girts (if I use wood). I'd probably use galvanized material for the purlins and girts but haven't got to that stage yet.

Here's a basic truss design to span a 30' barn or shop with a 4/12 pitch.

Pipe does present some problems though. It would require a lot of coping, and it's not as user friendly when it comes to mounting steel plates for purlins (if I use wood) and girts (if I use wood). I'd probably use galvanized material for the purlins and girts but haven't got to that stage yet.

Here's a basic truss design to span a 30' barn or shop with a 4/12 pitch.

Last edited:

Wow! That's really cool. I hadn't thought about the containers being outside of the roof.RK's idea is a good one too! "Clear Span" makes a nice product, as do others. Here's a link to their offerings:

HD Container Building | ClearSpan

I guess I should include a photo or two of a Kubota tractor in this thread. I used the new MX the other morning to move my 16' dump trailer from its winter storage location next to the barn to it's summer home next to the garage ... all of 30 yards  ... but it's so much easier hooking it up to the 3-point hitch than my Super Duty. It weighs 4,500 lb or more empty so I never tried moving it with the BX. The MX moved it like it was nothing.

... but it's so much easier hooking it up to the 3-point hitch than my Super Duty. It weighs 4,500 lb or more empty so I never tried moving it with the BX. The MX moved it like it was nothing.

I also used the MX on Friday to lift off and dispose of the old septic tank cover that was buried under 10" of dirt. I ordered and installed a riser with a new heavy duty plastic cover so won't need to dig a hole every time I need the tank pumped or inspected.

Here's the MX and PJ trailer just to the left of the barn that's still standing ... miraculously! I'll start moving stuff out shortly in preparation for the groundwork.

I would have used the BX to lift the septic cover off but it still has the front mount snow blower attached. It feels like spring here but you never know so I didn't want to jinx myself by putting the loader back on the BX too soon.

I also used the MX on Friday to lift off and dispose of the old septic tank cover that was buried under 10" of dirt. I ordered and installed a riser with a new heavy duty plastic cover so won't need to dig a hole every time I need the tank pumped or inspected.

Here's the MX and PJ trailer just to the left of the barn that's still standing ... miraculously! I'll start moving stuff out shortly in preparation for the groundwork.

I would have used the BX to lift the septic cover off but it still has the front mount snow blower attached. It feels like spring here but you never know so I didn't want to jinx myself by putting the loader back on the BX too soon.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

Here are some variations

This is what I was thinking of

containerking.com

containerking.com

They ship the structure in the container. Never knew about this

www.containertrusssystems.com

www.containertrusssystems.com

Kit roof for containers

westernshelter.com

westernshelter.com

More roof styles

www.steelmasterusa.com

www.steelmasterusa.com

This is what I was thinking of

Innovative Barns from Shipping Containers - Container King

Shipping container barns offer a modern and practical alternative to traditional wooden or metal barns. Their secure and stable design makes them ideal for

They ship the structure in the container. Never knew about this

Container Truss Systems | Got you covered, Anywhere

www.containertrusssystems.com

www.containertrusssystems.com

Kit roof for containers

CONTAINER ROOFS — Western Shelter

More roof styles

Container Covers

Perfect for commercial and larger residential storage solutions, SteelMaster's shipping container roof systems adds maximum space for minimal investment.

Here are some variations

This is what I was thinking of

Innovative Barns from Shipping Containers - Container King

Shipping container barns offer a modern and practical alternative to traditional wooden or metal barns. Their secure and stable design makes them ideal forcontainerking.com

They ship the structure in the container. Never knew about this

Container Truss Systems | Got you covered, Anywhere

www.containertrusssystems.com

Kit roof for containers

CONTAINER ROOFS — Western Shelter

westernshelter.com

More roof styles

Container Covers

Perfect for commercial and larger residential storage solutions, SteelMaster's shipping container roof systems adds maximum space for minimal investment.www.steelmasterusa.com

Those are amazing but I don't think the aesthetics of the quonset style roof would fit in here. It's a bit too industrial. I had thought about making a steel pitched roof on the container to keep water off and for extra storage. Your post has me thinking that two 20' containers side by side with perhaps a 4' gap and then a few trusses to make a roof would be useful. The problem with containers of course is access to stuff in the back. They're not ideal for that with doors on one end. A 40' container only exacerbates the problem.

I'm thinking that the containers should be a priority because I could use them to house the tractors while the barn is going up. Keep them out of the sun, rain and wind. Putting a roof on the containers wouldn't be a priority but something I could do after the barn is up.

I called the steel supplier yesterday and I'm rethinking the idea of using reclaimed pipe for the trusses. There are too many red flags so now I'm playing with a combination of 2"x2"x.125" and 1.75"x1.75"x.125". I will most likely use large reclaimed pipe for the columns because I'm much less worried about compression and buckling using a 5" pipe with a .25" wall, and the price is hard to beat.

Here ya go: Adding a door to your shipping container — Super CubesThose are amazing but I don't think the aesthetics of the quonset style roof would fit in here. It's a bit too industrial. I had thought about making a steel pitched roof on the container to keep water off and for extra storage. Your post has me thinking that two 20' containers side by side with perhaps a 4' gap and then a few trusses to make a roof would be useful. The problem with containers of course is access to stuff in the back. They're not ideal for that with doors on one end. A 40' container only exacerbates the problem.

I'm thinking that the containers should be a priority because I could use them to house the tractors while the barn is going up. Keep them out of the sun, rain and wind. Putting a roof on the containers wouldn't be a priority but something I could do after the barn is up.

I called the steel supplier yesterday and I'm rethinking the idea of using reclaimed pipe for the trusses. There are too many red flags so now I'm playing with a combination of 2"x2"x.125" and 1.75"x1.75"x.125". I will most likely use large reclaimed pipe for the columns because I'm much less worried about compression and buckling using a 5" pipe with a .25" wall, and the price is hard to beat.

A buddy of mine is thinking of doing this to his shipping container. With a plasma torch it shouldn't be too difficult to add doors whether a walk in or wider. Wide doors on the end and a walk in somewhere in between and under your roof would be pretty slick.

David

Cool. I called a container dealer this morning and a rep is coming out on Friday to take a look to see if they could deliver two 20' containers. Cost is around $10k for two "one trip" containers in good condition, and that includes delivery, setting the containers on 6"x6" treated wood blocks and leveling. Not cheap by any stretch, but the more I think about it, getting the containers set up first makes a lot of sense.Here ya go: Adding a door to your shipping container — Super Cubes

A buddy of mine is thinking of doing this to his shipping container. With a plasma torch it shouldn't be too difficult to add doors whether a walk in or wider. Wide doors on the end and a walk in somewhere in between and under your roof would be pretty slick.

David

I might need to build the gravel road first and then create a flat, graveled area for the containers. I'll definitely need to the do the latter but I'll see what the rep says about the road. He mentioned that they need a 12' x 70' unobstructed and relatively flat area to place the container. So I need to make sure that I have a 24' x 70' area for two. That includes the 8' x 20' spot for the container.

A quick update: One of the delivery guys from the container company came out to the house this morning to get a lay of the land. He confirmed that it would be impossible to get a single 40' container up to the house due to a tight bend at the top of the common driveway, but he'd have no problem getting a 20' container up here.

We discussed what I need to do in terms of grading and I've decided to have the containers placed end to end. Another option would be to get three 20' containers since there's no such thing as too much storage. Whatever I do I'll be adding a roof of some kind to make them look less like containers and to keep rain (it hardly rains here) and snow off the roof. If I'm clever about it I might even be able to gain some storage space on top of the containers for wood or steel.

Not sure why but my inserted linked images aren't working on this forum at the moment so I'll try a different approach.

Two containers

Three containers

We discussed what I need to do in terms of grading and I've decided to have the containers placed end to end. Another option would be to get three 20' containers since there's no such thing as too much storage. Whatever I do I'll be adding a roof of some kind to make them look less like containers and to keep rain (it hardly rains here) and snow off the roof. If I'm clever about it I might even be able to gain some storage space on top of the containers for wood or steel.

Not sure why but my inserted linked images aren't working on this forum at the moment so I'll try a different approach.

Two containers

Three containers

Last edited:

You do realize "pipe" is NOT intended for structural purposes, right?Those are amazing but I don't think the aesthetics of the quonset style roof would fit in here. It's a bit too industrial. I had thought about making a steel pitched roof on the container to keep water off and for extra storage. Your post has me thinking that two 20' containers side by side with perhaps a 4' gap and then a few trusses to make a roof would be useful. The problem with containers of course is access to stuff in the back. They're not ideal for that with doors on one end. A 40' container only exacerbates the problem.

I'm thinking that the containers should be a priority because I could use them to house the tractors while the barn is going up. Keep them out of the sun, rain and wind. Putting a roof on the containers wouldn't be a priority but something I could do after the barn is up.

I called the steel supplier yesterday and I'm rethinking the idea of using reclaimed pipe for the trusses. There are too many red flags so now I'm playing with a combination of 2"x2"x.125" and 1.75"x1.75"x.125". I will most likely use large reclaimed pipe for the columns because I'm much less worried about compression and buckling using a 5" pipe with a .25" wall, and the price is hard to beat.

A36 which is a low carbon "mild steel" is considered to be structural steel. Schedule 40 pipe has material properties that are similar to A36 but I understand your concern. The local steel supplier doesn't know what the pipe is exactly, only the dimensions, which aren't typical Schedule 40 values.You do realize "pipe" is NOT intended for structural purposes, right?

I've already designed the trusses using angle and will most likely use I-beams or box tubing for the columns since the pipe is a mystery product at this stage and better suited for fencing, decks and the like. The concern with steel columns is buckling so as long as 12' columns have a sufficient factor of safety with a load of 6,500lb I'm not worried.

If you mean tube, you're right, but pipe is not structural.A36 which is a low carbon "mild steel" is considered to be structural steel. Schedule 40 pipe has material properties that are similar to A36 but I understand your concern. The local steel supplier doesn't know what the pipe is exactly, only the dimensions, which aren't typical Schedule 40 values.

I've already designed the trusses using angle and will most likely use I-beams or box tubing for the columns since the pipe is a mystery product at this stage and better suited for fencing, decks and the like. The concern with steel columns is buckling so as long as 12' columns have a sufficient factor of safety with a load of 6,500lb I'm not worried.

We can go round and round on this but yes, tubing is generally chosen for structural projects and piping is generally used to transport fluids. However, that does not mean that a specific pipe section with a specific chemistry and set of material properties couldn't be used safely in a given situation. This is where data such as mechanical/material properties and predicted loading along with tools or disciplines such as math, statics, dynamics, finite element analysis and a slew of CAD related programs allow us to determine whether or not our design is safe.If you mean tube, you're right, but pipe is not structural.

I'm not going to dismiss the possible use of schedule 40 pipe over 1010 structural tubing simply because one has the word "structural" in the description. The material doesn't care what you call it.

I've modeled a 12' column of 4" schedule 40 pipe with a slit where the weld would be which is a worst case compared to welded pipe. Structural tubing is often welded too by the way. Using the mechanical properties of 1010 hot rolled steel which are lower than typical "low strength" schedule 40 pipe, applying a 6,500 lb load to the top of the pipe along with the force of gravity and running 5 buckling modes reveals the lowest factor of safety to be 1.8. So given all of that, would I be worried about buckling of a schedule 40 welded pipe with 30ksi yield strength sitting in 48" of concrete supporting a truss (fs = 1.5) designed to resist a 50 year snow event where I live ... not really.

Im gonna go on a limb and say... you've got this one covered. Welded trusses and all!... My career path has been construction laborer > welder > commercial diver/welder > mechanical engineer and currently am an engineer in the firearms industry.