Engine wouldn't turn over. Charged the battery, replaced both battery cables, and key switch (starter switch) and engine started. Now it wont turn off. Fuse #7 for timer/solenoid was checked and had blown. Replaced it and it blew immediately. Is the problem with the timer or solenoid? Not sure what the timer looks like. Any help appreciated. Dennis

RTV900R shutoff

- Thread starter dennishowens

- Start date

In my experience (replacing 100s of keyswitches), I have discovered that there are several types which have identical pinouts... but electrically are different.

Based on your two problems (wont shut off and fuse blowing), I would suggest that you make certain the keyswitch is the proper one.

Try 'bathing' the original keyswitch in WD40 and exercizing it about 50 times.... it may come back to life.

Based on your two problems (wont shut off and fuse blowing), I would suggest that you make certain the keyswitch is the proper one.

Try 'bathing' the original keyswitch in WD40 and exercizing it about 50 times.... it may come back to life.

Will give that a try. Never thought that new key switch could be the problem.In my experience (replacing 100s of keyswitches), I have discovered that there are several types which have identical pinouts... but electrically are different.

Based on your two problems (wont shut off and fuse blowing), I would suggest that you make certain the keyswitch is the proper one.

Try 'bathing' the original keyswitch in WD40 and exercizing it about 50 times.... it may come back to life.

9mmonWill give that a try. Never thought that new key switch could be the problem.

Tried the old switch after bathing in wd40 and recycling switch many times. Starts fine but still will not cutoff. Fuse no. 7 blew again.9mmon

The following is a supposition:

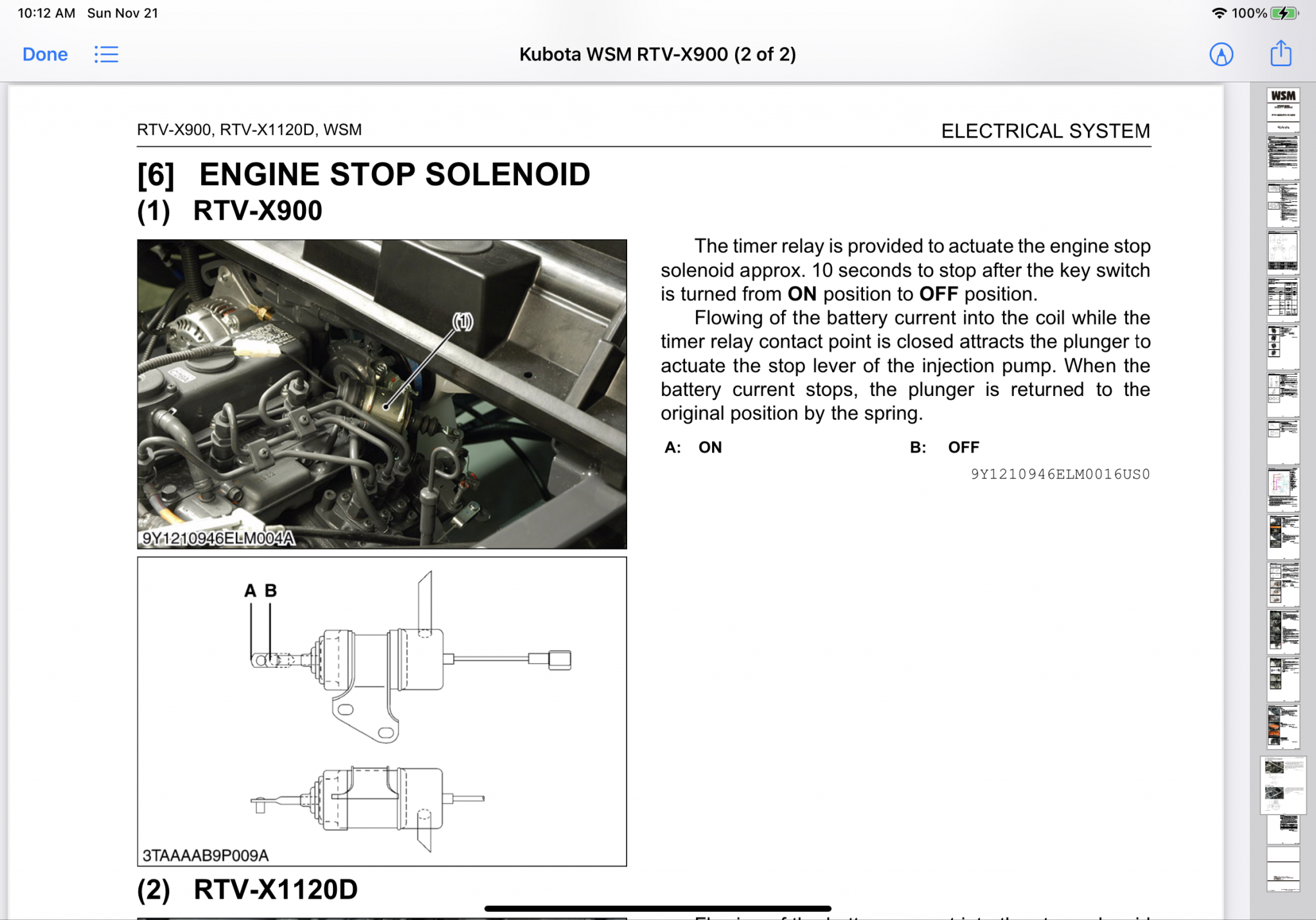

The RTV 900 series has a solenoid-actuated fuel-shut-off solenoid which is activated thru a timer. The fuel shut-off is normally open so the engine can start and run. When the key is turned OFF the power to close the shut-off is delivered to close the valve via a timer…which about 10 seconds after being activated…releases back to the open position.

It sounds as if your timer or the fuel shut off and/or its’ circuit has a ”short” and needs repair.

I own a RTV-X900 which is a later model and slightly different but I believe the diesel powered RTVs operate similarly. Here is the WSM section which deals with this on the X900

The RTV 900 series has a solenoid-actuated fuel-shut-off solenoid which is activated thru a timer. The fuel shut-off is normally open so the engine can start and run. When the key is turned OFF the power to close the shut-off is delivered to close the valve via a timer…which about 10 seconds after being activated…releases back to the open position.

It sounds as if your timer or the fuel shut off and/or its’ circuit has a ”short” and needs repair.

I own a RTV-X900 which is a later model and slightly different but I believe the diesel powered RTVs operate similarly. Here is the WSM section which deals with this on the X900

Last edited:

I should be able to remove the timer and test for a short. Will do that. Not for sure where the timer is located but believe its next to fuse box on firewall. Incidentally, fuse 7 has 12 volts on one side even with ignition switch off. Not sure that matters. Thanks for suggestion.The following is a supposition:

The RTV 900 series has a solenoid-actuated fuel-shut-off solenoid which is activated thru a timer. The fuel shut-off is normally open so the engine can start and run. When the key is turned OFF the power to close the shut-off is delivered to close the valve via a timer…which about 10 seconds after being activated…releases back to the open position.

It sounds as if your timer or the fuel shut off and/or its’ circuit has a ”short” and needs repair.

I own a RTV-X900 which is a later model and slightly different but I believe the diesel powered RTVs operate similarly. Here is the WSM section which deals with this on the X900 View attachment 70130

I think your FIRST thing to do.. is see if your fuel-shut-off solenoid is shorted out. Hook an alligator clip jumper to it with a fuse….and try to operate it…. if the fuse blows…..

whitetiger

Moderator

Staff member

Equipment

Kubota tech..BX2370, RCK60, B7100HST, RTV900 w plow, Ford 1100 FWA

Unplug the white wire to the shutoff solenoid and see if your fuse still blows. If it doesn't, the solenoid has failed.

Here is a pdf on the timer and a wiring diagram.

Here is a pdf on the timer and a wiring diagram.

Attachments

-

778 KB Views: 491

-

879.5 KB Views: 383

Just so we are clear here.... Is this what lead up to where we are?Tried the old switch after bathing in wd40 and recycling switch many times. Starts fine but still will not cutoff. Fuse no. 7 blew again.

- the machine worked flawlessly until one day it wold not turn over

- The battery, cables and keyswitch was replaced and now it wont shutoff and a fuse blows.

Many years of working on equipment tells me that SOMETHING else has happened which is not understood.

------------------------------

In any case... follow the problem.

Here is one troubleshooting approach:

- Wire a LIGHTBULB inplace of where the fuse goes (Approximate bulb wattage based on Amp value of fuse which is blowing) [Use ohms law to determine bulb wattage]

- Turn on keyswitch and EXPECT bulb to light due to too much current-draw

- Begin disconnecting things in the circuit (shutoff solenoid, timer) looking for when the bulb brightness drops or goes out.

- The goal is to isolate what is drawing the current.

Last edited:

THAT’S just ridiculously overly-complicated …without some math done beforehand. The ‘lightbulb”….What, exactly, is the “wattage” you recommend? it’s a 12-14 volt system…. why didn’t you specify what you meant?

Simpler answer: Fuses are NOT expensive. Don’t make this more complicated than necessary.

Simpler answer: Fuses are NOT expensive. Don’t make this more complicated than necessary.

disconnect the solenoid. Turn the key on, then right back off. Does the fuse blow? If yes you have a wiring problem or perhaps (though not likely) timer issue. Likely a short circuit, maybe rodent damaged, etc. If it don't blow the fuse, the solenoid is pulling more amperage than the fuse is rated for.

by chance did ya hook up the battery backwards at some point?

by chance did ya hook up the battery backwards at some point?

No, never hooked up battery backwards. Will remove wire to solenoid and see if it still shorts fuse.disconnect the solenoid. Turn the key on, then right back off. Does the fuse blow? If yes you have a wiring problem or perhaps (though not likely) timer issue. Likely a short circuit, maybe rodent damaged, etc. If it don't blow the fuse, the solenoid is pulling more amperage than the fuse is rated for.

by chance did ya hook up the battery backwards at some point?

You did not specify the AMPERAGE of the fuse which is blowing hence I am unable to specify the WATTAGE of the bulb.THAT’S just ridiculously overly-complicated …without some math done beforehand. The ‘lightbulb”….What, exactly, is the “wattage” you recommend? it’s a 12-14 volt system…. why didn’t you specify what you meant?

My goodness, basic electronics is not rocket science. There is nothing special about using a lightbulb to replace a fuse to troubleshoot problems. This is how many 12v electronics circuits are troubleshot when a fuse is blowing.

Generally, a fuse amperage is specified approximately 3x of the expected current. (30% rule)

As an example, if it is a 10A fuse which is blowing, 1/3 of that is about 3 amps.

We know WATTS = AMPS x VOLTS ...hence 3Ax12V=36Watts

Any bulb below 36W would be 'safe' to use.

You need to do your own calculation based on the amperage of the fuse which is blowing.

I keep old 12v bulbs which I replace in my vehicles to use as troubleshooting aids. Simply solder on a couple wires with clips so it is easy to clip to a fuse.

It should go without saying that too HIGH a wattage bulb may not protect the circuit and too LOW an amperage bulb may not allow enough current thru it. (it would be lit all the time...even if circuit is working as expected)

There are other ways to troubleshoot the issue you describe... but the one I have explained above is simple and provides a visual aide (a lit bulb) to help isolate a problem.

--------------

Other troubleshooting methods would include:

- Using an OHMmeter. (resistance) [disconnect battery before using this method]

- Using an AMPmeter (not recommended unless one is VERY aware of electron-flow dynamics)

- Disconnecting things to see the results (may not isolate the problem)

- Guessing (blindly replacing parts hoping it works) [most expensive way to fix something]

Last edited:

Bruce, you’re supposition is incorrect. Fuse size is not determined by the appliance current-draw as you suggest.

Fuses do not protect the appliance. Fuses protect the Wire.

Fuses are sized according to wire-gauge.

We do not know if the fuse he specified is the correct size for the circuit, …and it’s unknown what the req’d current is for a healthy solenoid…. so I felt it was overly-complicated to calculate what size light bulb to use in your suggested test apparatus since neither the appliance OR the fuse which keeps blowing …whichever is known to be the problem. As you’ve already noticed, he didn’t mention the fuse-rating which was failing… His fuse might be too small for the appliance (the fuel shut off solenoid..in which your apparatus may or may not be helpful.)

Fuses are cheaper than light bulbs.

I felt it was simpler to disconnect the solenoid and see if it still blows a cheap fuse…. which would lead to discovery of a short …OR…an inappropriate fuse (which I admit I failed to point-out in my suggested method.)

Dennis…what size fuse ARE we discussing…??

Fuses do not protect the appliance. Fuses protect the Wire.

Fuses are sized according to wire-gauge.

We do not know if the fuse he specified is the correct size for the circuit, …and it’s unknown what the req’d current is for a healthy solenoid…. so I felt it was overly-complicated to calculate what size light bulb to use in your suggested test apparatus since neither the appliance OR the fuse which keeps blowing …whichever is known to be the problem. As you’ve already noticed, he didn’t mention the fuse-rating which was failing… His fuse might be too small for the appliance (the fuel shut off solenoid..in which your apparatus may or may not be helpful.)

Fuses are cheaper than light bulbs.

I felt it was simpler to disconnect the solenoid and see if it still blows a cheap fuse…. which would lead to discovery of a short …OR…an inappropriate fuse (which I admit I failed to point-out in my suggested method.)

Dennis…what size fuse ARE we discussing…??

I understand that... however, we are trying to keep this 'simple' for Mr. dennishowensFuses do not protect the appliance. Fuses protect the Wire.

I fully understand your approach to this problem. We are both trying to help. Remote-control troubleshooting is never easy. (especially when basic electronics is not well understood)I felt it was simpler to disconnect the solenoid and see if it still blows a cheap fuse…. which would lead to discovery of a short …OR…an inappropriate fuse (which I admit I failed to point-out in my suggested method.)

------------------------------

Lets not forget that cheep, Chineese fuses are NOTORIOUS for being inaccurate and do not blow at the proper current. The scourge of cheep Chineese parts does not help those of us who fix things. Many of the parts are bad out of the box or fail quickly.

It is my opinion that it is FARRRR better to isolate the fail and fix it properly than to contaminate our Kubota's with multitudes of Chineesium parts. We own a Kubota for a reason... if we wanted a Chineese tractor with all its faults, we would not own a Kubota.

Last edited:

Ok…. so are we simplifying things by requiring some light-bulb-test-apparatus-construction-calculation…??I understand that... however, we are trying to keep this 'simple' for Mr. dennishowens

Or is it simpler to disconnect the plug on the solenoid and see if it still blows the fuse.

Ok…. so are we simplifying things by requiring some light-bulb-test-apparatus-construction-calculation…??

Or is it simpler to disconnect the plug on the solenoid and see if it still blows the fuse.

I actually considered suggesting that very thing... but I feared that Mr. @dennishowens may make too many assumptions about what the results of that test mean.

My hope is that Mr. @dennishowens gains some knowledge about electronics troubleshooting and may be able to fix this and future problems for himself. (This is what personally would want if I was learning something new)

-------------------

You do not know how many forums I follow regarding automobile troubleshooting. WAYYYY too many folks think that a "code" reported by their OBDII codereader means that a sensor is 'bad'. They replace a perfectly good sensor with a defective Chineesium part and make the problem worse.

The reality is that a codereader is a troubleshooting tool and not a problem diagnoser.

Last edited:

The disconnect of the solenoid wire stopped the fuse no. 7 (15 amp) from blowing. I have ordered a new solenoid. The wiring at the solenoid is brittle. Hope I dont have to replace the wiring. The connector wouldn't come apart. Had to snip the wire. Sixty years ago, I learned that you fuse the wire, not the load. Used to be an electrician. Be glad to get this running correctly as its interfering with my bird hunting.Engine wouldn't turn over. Charged the battery, replaced both battery cables, and key switch (starter switch) and engine started. Now it wont turn off. Fuse #7 for timer/solenoid was checked and had blown. Replaced it and it blew immediately. Is the problem with the timer or solenoid? Not sure what the timer looks like. Any help appreciated. Dennis

Thanks for all the suggestions, especially the wiring diagrams. Happy Thanksgiving to all.

thanks for posting a solution.The disconnect of the solenoid wire stopped the fuse no. 7 (15 amp) from blowing. I have ordered a new solenoid. The wiring at the solenoid is brittle. Hope I dont have to replace the wiring. The connector wouldn't come apart. Had to snip the wire. Sixty years ago, I learned that you fuse the wire, not the load. Used to be an electrician. Be glad to get this running correctly as its interfering with my bird hunting.

Thanks for all the suggestions, especially the wiring diagrams. Happy Thanksgiving to all.

i am fighting a similar issue, with a scag mower. Pto clutch draws like 15 amps, and the charging system only puts out about 18, so with the electric fuel pump and everything else running, with pto is on, the charge wire gets hot, the regulator gets really hot, and the fuse, after a while, will bust (15A). I called the manufacturer of the clutch and it's only supposed to "pull" about 3-5 amps max. Guy said the electromagnetic coil is probably broken internally; although an ohm test shows fine. A great example of an ohm test being inconclusive. new clutch on the way.