There are a couple of themes that keep showing up on the forum, one is bleeding fuel lines, and the other is use of fuel additives. Bleeding especially is tractor specific, and I wanted to understand how mine worked, and I have some questions. I waded through a bunch of the parts diagrams, and thought I would share those, but I still am stuck on a couple things.

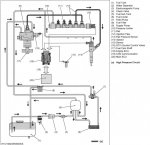

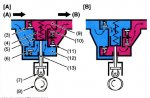

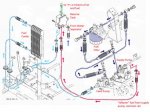

The first is a functional diagram from the wsm, but it doesn't give much clue as to what the items actually look like, and for the flow diagram it doesn't tell you whether the dotted lines mean "largely carries air", "only flows sometimes" or what.

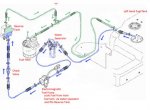

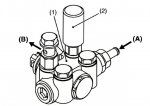

How it works is not obvious just looking at the fuel lines themselves!

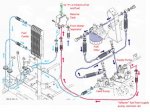

Note added several weeks later: the flow diagrams ended up being revised. New and improved versions are added later further down in the thread.

The first is a functional diagram from the wsm, but it doesn't give much clue as to what the items actually look like, and for the flow diagram it doesn't tell you whether the dotted lines mean "largely carries air", "only flows sometimes" or what.

How it works is not obvious just looking at the fuel lines themselves!

Note added several weeks later: the flow diagrams ended up being revised. New and improved versions are added later further down in the thread.

Attachments

-

85.3 KB Views: 11,700

-

91.5 KB Views: 2,266

Last edited: