torch

Well-known member

Equipment

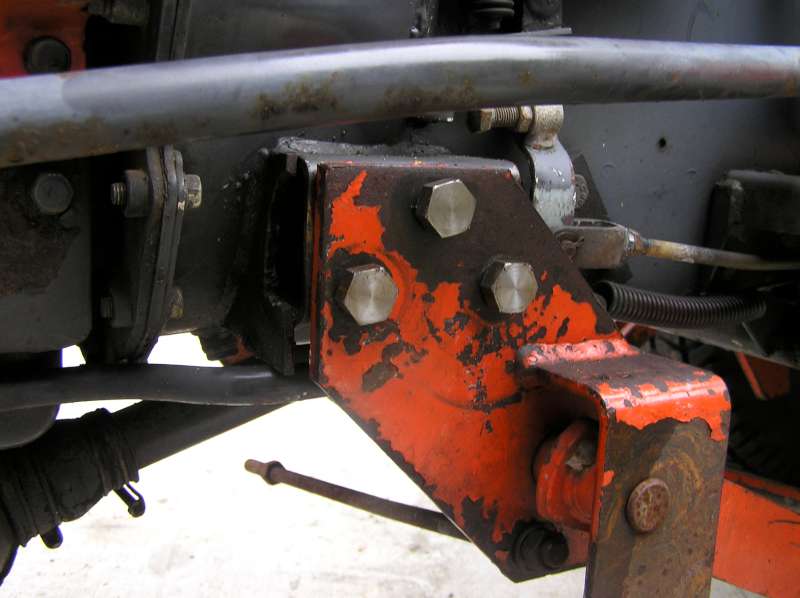

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Well Kubota is clearly under the impression you can. From the manual:I don't think you can drive over the deck in either direction.

Then a pretty picture of the deck (with all wheels chocked in both directions) in front of the tractor with a big arrow and the caption "Drive over forward".(5.1) Attaching the mower.

- put chocks at the gauge wheels

- run the tractor at low speed when riding over the mower.

- put the mower's rear link at its upward position.

- attach the belt cover securely.

- remove all parts attached to the tractor's 3 point hitch before backing over the mower.

Moving on to removal instructions:

Then there's a pretty picture with the deck underneath the mower this time (again, with all wheels chocked in both directions), a big black arrow pointing forward and the caption "Drive over forward".- Block the gauge wheels of the mower deck with the chocks

- run the engine at low speed for the mower removal

- remove all attachments attached to the tractor's 3 point hitch before moving the tractor forward for removal of the mower.

- take the opposite process of 5.1 (2) to (4) for mounting.

If it actually works then it seems like the hardest part of the whole process is connecting the PTO. However, when I measure the clearance between the gauge wheel brackets, I get 42". The front wheels are 44" outside to outside and the rear wheels are 45". So you may well be right that this won't work!

One thing that I expected to be mentioned is to raise all the guide wheels so the deck is at minimum height before driving over.

Last edited: