kubotafreak

Well-known member

Equipment

GRAND l6060, L3560, B6100, gr2100, tg 1860, g1800, g1900, g2160

Nice find Ruger1980, No one is trying to question your sanity on reading part diagrams. Me, lugbolt, and dgtvrpepair have spent plenty of time looking at what is physically in front of us.

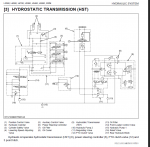

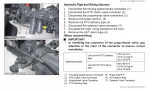

I honestly never looked at the WSM since how dgtvrpepair described made perfect sense to what is visually in front of me on my machine. Given the nature of hose clamps on the cooler I would have never imagined the soft hoses on the driver side, being supplied return flow (to pump, not tank)from the hst housing. If you check the schematic one side is worm clamps the other is wire clamps. This initially lead me to believe the only reason for the hose worm clamps is the pressure drop across the cooler from the pump/steering side.

I still believe air ingress whether through intake or cavitation, is the source of all the problems. Your findings have only complicated the solution to this problem. Mine has a noticeable drop in performance after 2 hours of working the machine. I can tell there is air/cavitation happening in the pump lines at startup (hissing). Machine has less than 50 hours, so I am very interested in fixing this annoyance. Heat in the fluid is the result of my issues, since it takes time for mine to exhibit any symptoms. I can say that on my last l60 series it had several hundred hours and the "worn in pump, steering, hst" seemed to show signs sooner, if not immediately with the steering delay as well has the heat soak hydraulic fluid over time. I am not so concerned with the steering delay myself, as that seems livable, however I cant have the machine loosing power just because of a hydraulic system flaws.

Sounds to me if we go off the prior findings of dgtvrpepair, the hst is returning dirty, "aeriated" fluid back to the system. Which if I'm right, is a little disheartening, because it may not be something we can engineer out of. This might come down to installing clear tubing in the cooler to see the air bubbles.

I have little faith in any dealer level "repair", as we all seem to agree this is a design flaw. I like my dealer, and Kubota products to the fullest. This just seems to be an issue WE must remedy ourselves. If I had not read plenty of others getting pumps, controllers, cylinders, and hoses replaced already I may think otherwise.

I honestly never looked at the WSM since how dgtvrpepair described made perfect sense to what is visually in front of me on my machine. Given the nature of hose clamps on the cooler I would have never imagined the soft hoses on the driver side, being supplied return flow (to pump, not tank)from the hst housing. If you check the schematic one side is worm clamps the other is wire clamps. This initially lead me to believe the only reason for the hose worm clamps is the pressure drop across the cooler from the pump/steering side.

I still believe air ingress whether through intake or cavitation, is the source of all the problems. Your findings have only complicated the solution to this problem. Mine has a noticeable drop in performance after 2 hours of working the machine. I can tell there is air/cavitation happening in the pump lines at startup (hissing). Machine has less than 50 hours, so I am very interested in fixing this annoyance. Heat in the fluid is the result of my issues, since it takes time for mine to exhibit any symptoms. I can say that on my last l60 series it had several hundred hours and the "worn in pump, steering, hst" seemed to show signs sooner, if not immediately with the steering delay as well has the heat soak hydraulic fluid over time. I am not so concerned with the steering delay myself, as that seems livable, however I cant have the machine loosing power just because of a hydraulic system flaws.

Sounds to me if we go off the prior findings of dgtvrpepair, the hst is returning dirty, "aeriated" fluid back to the system. Which if I'm right, is a little disheartening, because it may not be something we can engineer out of. This might come down to installing clear tubing in the cooler to see the air bubbles.

I have little faith in any dealer level "repair", as we all seem to agree this is a design flaw. I like my dealer, and Kubota products to the fullest. This just seems to be an issue WE must remedy ourselves. If I had not read plenty of others getting pumps, controllers, cylinders, and hoses replaced already I may think otherwise.

Attachments

-

456.4 KB Views: 294