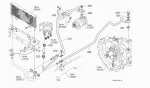

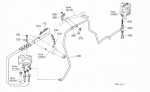

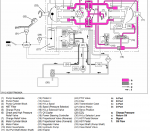

Interesting.I have had the same problem, I have been dealing with it for years. Mine is l4760 hydro- same hydraulics as yours. Had it to dealer many times and nothing has repaired it. I purchased the service manual to try and figure it out myself. The service manual is wrong. The hydraulics in it are for the l3560 and the l4060 and up are plumbed different. I found the parts diagrams on messick's by my model. You have to register to see them. If you follow the output of the pump through the steering controller the return fluid tees and goes through cooler back to tank or can bypass cooler and go back to suction of pump top metal line that is by large suction on pump. I found that when demand was needed it was sucking the oil out of the steering controller causing loss of steering when going forward to reverse and try to steer. It got really bad after mowing for an hour or 2, I plugged off the return of pipe 040 to return of pump. now oil goes from pump to steering controller out to oil cooler then returns to tank. Now it can't bypass cooler and keep heating same oil over and over, and it can't be pulled out of controller backward. No more loss of steering and better yet stall guard works so much smoother. Before in stall guard and auto hydrostat the tractor rpm would drop slightly and it would drop to low range fast and back fast with very little rpm change, Now when tractor rpm drops close to 540 when mowing tall grass, speed slows down and the rpm stays at 540 and doesn't drop ranges as rpm builds back above 540 the speed starts going back up. It will still drop ranges as it should just not so fast. I can now change directions as fast as I want and no loss of steering. I have ran it 8 hours this way. I explained this to my dealer and they are lost. It is a definite design flaw.

Can you provide details of what is necessary to make the modification?

SDT