^^^^

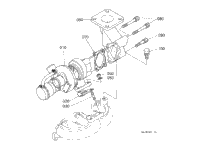

Definitely a AN fitting connection issue. I have a new AN fitting on the way and look forward to having a leak-free L2501 Turbocharger experience!

In addition, we updated the Turbo Charge Pipe so that the OEM factory hood prop rod absorber can function as intended;

Mike

Definitely a AN fitting connection issue. I have a new AN fitting on the way and look forward to having a leak-free L2501 Turbocharger experience!

In addition, we updated the Turbo Charge Pipe so that the OEM factory hood prop rod absorber can function as intended;

Mike