Hi all,

First let me give thanks to all the post that has helped me getting my tractor up and running.

I am in Thailand. I am not Thai. Got a Japanese B5001 in about 90% condition with a rs900 rotovator. Full checkup and service, and it was a go!

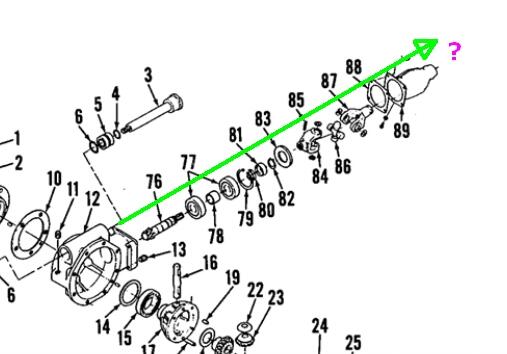

I noticed in 5th and 6th gear when running a bit faster there is a 'whizzing' mechanical noise from the mid section. Not noticeable in 4th gear as the tractor goes too slow. This noise is there with and without 4x4 engaged and with and without pulling a wagon or the rotovator attached.

I am thinking bearing? Clutch? It is not giving any problems right now but I'd like to get it sorted out already.

There is a guy in our village that has a B2000, basically a big brother version of mine. I have asked him and he does not know. His does not do that.

Any comments on this?

First let me give thanks to all the post that has helped me getting my tractor up and running.

I am in Thailand. I am not Thai. Got a Japanese B5001 in about 90% condition with a rs900 rotovator. Full checkup and service, and it was a go!

I noticed in 5th and 6th gear when running a bit faster there is a 'whizzing' mechanical noise from the mid section. Not noticeable in 4th gear as the tractor goes too slow. This noise is there with and without 4x4 engaged and with and without pulling a wagon or the rotovator attached.

I am thinking bearing? Clutch? It is not giving any problems right now but I'd like to get it sorted out already.

There is a guy in our village that has a B2000, basically a big brother version of mine. I have asked him and he does not know. His does not do that.

Any comments on this?