Hello, I am new to the forum and have recently purchased a B7100d with a B219 fel. The fel was complete other than the pump and the hydraulic control valve. I plan on buying a control valve but have read on here that some people have hooked up to the hydraulic system of the tractor. Could some one share pics on where to make the hydraulic connections for this to work correctly. Thanks

Installing B219 fel but no front mount hydraulic pump.

- Thread starter Jwgood

- Start date

whitetiger

Moderator

Staff member

Equipment

Kubota tech..BX2370, RCK60, B7100HST, RTV900 w plow, Ford 1100 FWA

These PDFs will show how it needs to be plumbed to the tractor.

Attachments

-

120.9 KB Views: 209

-

58.8 KB Views: 194

Any tricks to viewing them? Not having any luck. ThanksThese PDFs will show how it needs to be plumbed to the tractor.

I personally helped a friend install a FEL on a B7100. This was years ago but some details are firmly fixed in my mind.

I wish we had the details including part numbers which Whitetiger has provided you.

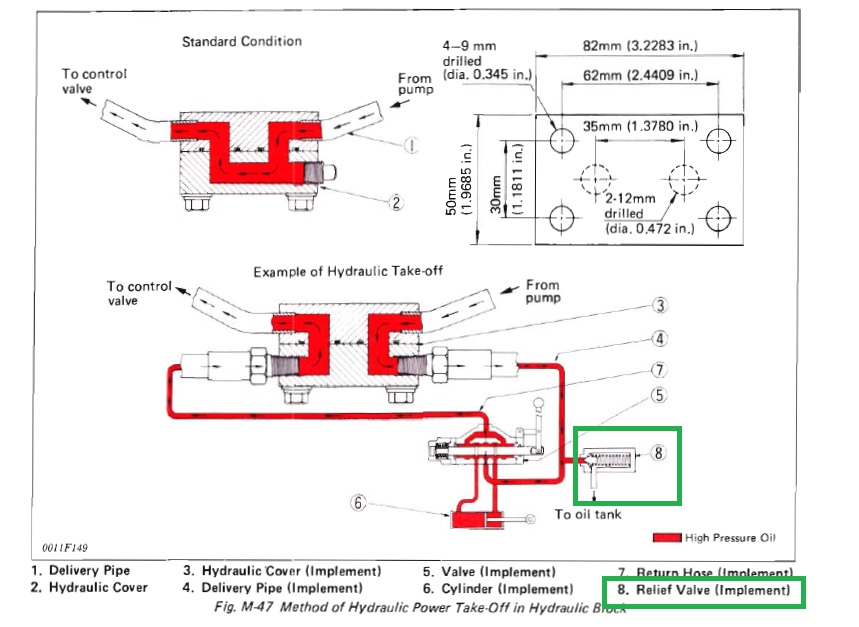

The B7100 WSM, available free on Kubotabooks.com, has an excellent color illustration of how the new outlet block cover is to be connected to a new valve. Presently, the B7100's only hydraulic system pressure relief valve is at the 3 pt hitch end of the tractor.

Kubotabooks.com

Using the new outlet block cover to install a loader valve between the main pump and the rear of the tractor cuts the only pressure relief valve out of the circuit and exposes the main pump to severe damage.

The new loader valve must have its own pressure relief valve. Most new valves do but it is a critical part of a successful installation.

In this illustration the relief valve marked with a green box is exterior to the new valve but this is just for explanatory purposes.

A common mistake owners make when buying a loader valve is to buy the one with the most gpm rating. This is the opposite of what you want to do and will make controlling your loader very difficult.

The B7100 has a gpm rating of almost 3 gpm which is small.

Recently a forum member was installing a new loader valve. He made a decision which will be valuable in the future. His new valve had the two common spools controlled by a joystick but as part of the same valve body was a third spool controlled by an individual lever. This third spool was provided to control a future grapple.

Most hydraulic valves are not designed to tolerate high pressures on their TANK port. You should be using a power beyond port for the oil being fed from the new loader valve back into the hydraulic system going to the rear of the tractor. PB is usually a $25 option you need to buy when you buy your new valve..

This is the 3 spool valve the B2400 owner had ordered.

3 spool valve

These are images of the PB sleeve. They are unique for a particular series of valves in this case a Badestnost 40 series.

A plug in the new valve body is removed and the PB sleeve is screwed in. The sleeve creates an additional port on the valve body.

Forum member Win22wrf, who has a B7100, has suggested this 8 gpm valve in the past.

Prince valve

If at any time during your project you are uncertain, dont try something to see if it will work. This is not a good strategy with hydraulics. come back with questions until you know exactly what you need to do.

Dave

I wish we had the details including part numbers which Whitetiger has provided you.

The B7100 WSM, available free on Kubotabooks.com, has an excellent color illustration of how the new outlet block cover is to be connected to a new valve. Presently, the B7100's only hydraulic system pressure relief valve is at the 3 pt hitch end of the tractor.

Kubotabooks.com

Using the new outlet block cover to install a loader valve between the main pump and the rear of the tractor cuts the only pressure relief valve out of the circuit and exposes the main pump to severe damage.

The new loader valve must have its own pressure relief valve. Most new valves do but it is a critical part of a successful installation.

In this illustration the relief valve marked with a green box is exterior to the new valve but this is just for explanatory purposes.

A common mistake owners make when buying a loader valve is to buy the one with the most gpm rating. This is the opposite of what you want to do and will make controlling your loader very difficult.

The B7100 has a gpm rating of almost 3 gpm which is small.

Recently a forum member was installing a new loader valve. He made a decision which will be valuable in the future. His new valve had the two common spools controlled by a joystick but as part of the same valve body was a third spool controlled by an individual lever. This third spool was provided to control a future grapple.

Most hydraulic valves are not designed to tolerate high pressures on their TANK port. You should be using a power beyond port for the oil being fed from the new loader valve back into the hydraulic system going to the rear of the tractor. PB is usually a $25 option you need to buy when you buy your new valve..

This is the 3 spool valve the B2400 owner had ordered.

3 spool valve

These are images of the PB sleeve. They are unique for a particular series of valves in this case a Badestnost 40 series.

A plug in the new valve body is removed and the PB sleeve is screwed in. The sleeve creates an additional port on the valve body.

Forum member Win22wrf, who has a B7100, has suggested this 8 gpm valve in the past.

Prince valve

If at any time during your project you are uncertain, dont try something to see if it will work. This is not a good strategy with hydraulics. come back with questions until you know exactly what you need to do.

Dave

Thanks for the info.... I am a toolmaker and work at a shop that builds automated equipment. Our hydraulics guy in the shop wanted to about putting it in parallel with the tractor system instead of series? Have you heard of anyone trying this. If anyone has what are the pros and cons ?

Ask your shop guys if they have experience with OPEN CENTER systems with fixed displacement pumps.Thanks for the info.... I am a toolmaker and work at a shop that builds automated equipment. Our hydraulics guy in the shop wanted to about putting it in parallel with the tractor system instead of series? Have you heard of anyone trying this. If anyone has what are the pros and cons ?

I expect their experience is with Closed Center systems with much more expensive variable displacement pumps.

Some much bigger JD's use the CC system.

In short in parallel nothing will work.

Dave

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

I did exactly what you are thinking of when I built my FEL:

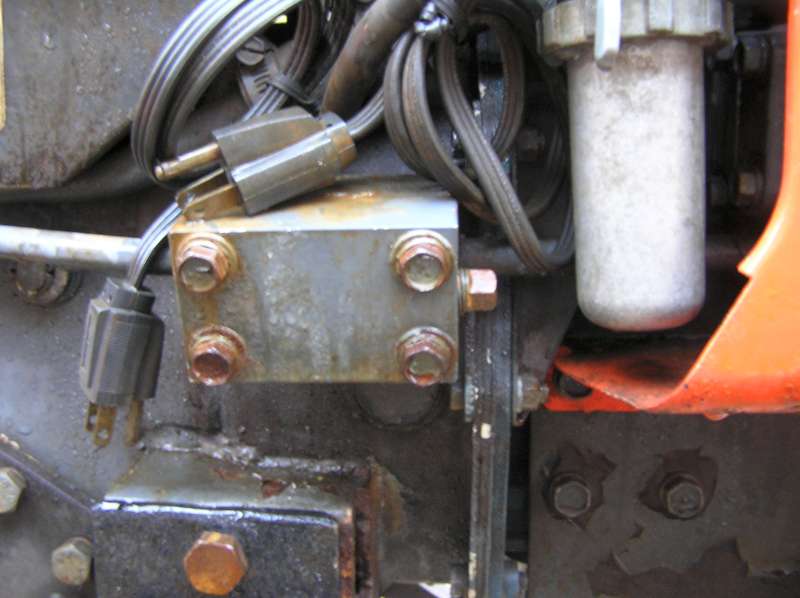

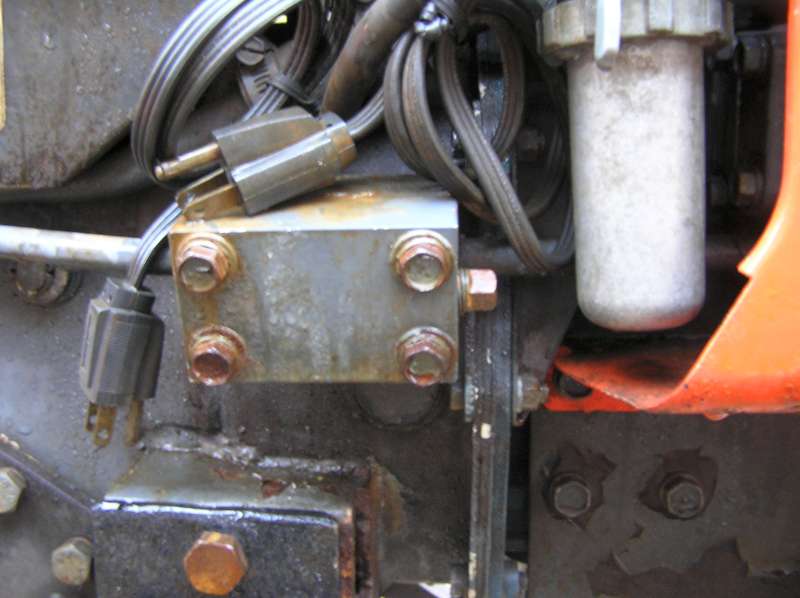

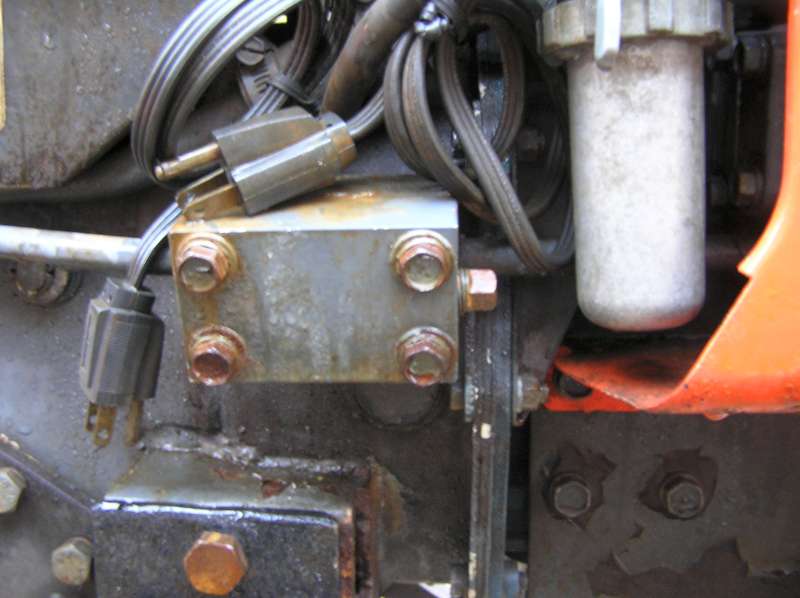

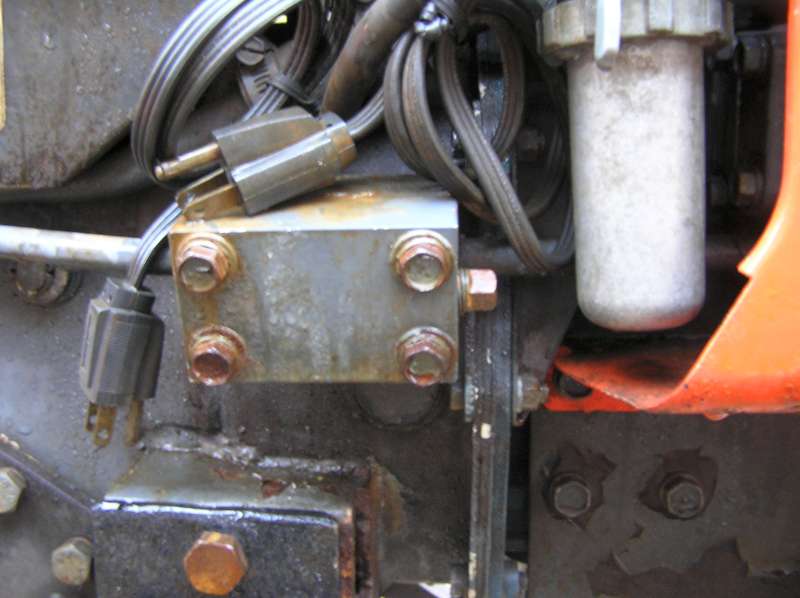

The hydraulic block, as delivered:

Old cover removed:

New cover created by drilling and tapping a suitable block of steel (aluminium would probably be fine too) as per the dimensions in the manual, like so. Inside (left) and outside (right) of block shown). I tapped mine for 3/4" NPT. I tapped an extra hole, for possible future use or a gauge, on the outside face, and plugged the unused hole with a pipe plug. (The extra block went to another forum member who was also adding a FEL.)

The hydraulic block, as delivered:

Old cover removed:

New cover created by drilling and tapping a suitable block of steel (aluminium would probably be fine too) as per the dimensions in the manual, like so. Inside (left) and outside (right) of block shown). I tapped mine for 3/4" NPT. I tapped an extra hole, for possible future use or a gauge, on the outside face, and plugged the unused hole with a pipe plug. (The extra block went to another forum member who was also adding a FEL.)

Thanks again for all the help guys! I have the valve and some fittings ordered and I made the new block for tapping into the system. Will let you all know how it goes when the parts get here.

If you have time could you give me an explanation of the problems with this in parallel? Just for the purpose of educating myself. If you don't have time I understand and thanks again for the help.Ask your shop guys if they have experience with OPEN CENTER systems with fixed displacement pumps.

I expect their experience is with Closed Center systems with much more expensive variable displacement pumps.

Some much bigger JD's use the CC system.

In short in parallel nothing will work.

Dave

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Open centre means the system constantly circulates oil from the pump to the reservoir under very little pressure until a spool valve is activated. Closed centre systems do not circulate oil, they maintain a high pressure at all times.

An open centre system cannot supply two separate control valves simultaneously. A closed centre system can.

An open centre system can supply more than one separate control valve, however all but the last one in the chain requires 3 hoses -- one from the pump, one back to the reservoir, and one to the next control in the chain (known as the "Power Beyond" hose). In other words, the valves are in series. A closed centre system only requires two hoses per separate control valve -- one from the pump and one to the reservoir. In other words, the valves are in parallel.

Practical example: Open centre system with FEL as first control in the chain. Raising the FEL prevents the 3PH from lifting (it may even fall if the 3ph valve is activated while raising the FEL). To raise both, lift one at a time. Each will lift at normal speed.

Closed centre system: raising the FEL and 3ph can be done simultaneously, both will lift but will lift slowly.

An open centre system cannot supply two separate control valves simultaneously. A closed centre system can.

An open centre system can supply more than one separate control valve, however all but the last one in the chain requires 3 hoses -- one from the pump, one back to the reservoir, and one to the next control in the chain (known as the "Power Beyond" hose). In other words, the valves are in series. A closed centre system only requires two hoses per separate control valve -- one from the pump and one to the reservoir. In other words, the valves are in parallel.

Practical example: Open centre system with FEL as first control in the chain. Raising the FEL prevents the 3PH from lifting (it may even fall if the 3ph valve is activated while raising the FEL). To raise both, lift one at a time. Each will lift at normal speed.

Closed centre system: raising the FEL and 3ph can be done simultaneously, both will lift but will lift slowly.

Last edited:

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Note, some open centre control valves will allow simultaneous operation of FEL functions (eg: lift and curl) very much like a closed centre system. Don't confuse operation of the individual spool valves in a control valve set with separate control valves.

I will gladly try to increase your knowledge of these two types of systems.If you have time could you give me an explanation of the problems with this in parallel? Just for the purpose of educating myself. If you don't have time I understand and thanks again for the help.

To start with try and use the terms Open Center and Closed Center .with the closed center being the parallel one your work mates speak of and use.

The parallel system is the most sophisticated one which offers the most precision in performance. You will have seen backhoe or excavator operators able to gently pick up a man and lower him into an excavation. Certainly contrary to safety regulations but it happens every day. Why does it happen..... workers feel safe and protected standing in a bucket. It is like being moved by the Gentle Giant some of us young kids knew as a TV character. The motion is slow and smooth.

If you are running large excavators 24 hours a day in a mining operation, the cost of the fuel you use is an important component of the cost equations which determine if you are making or loosing money. Experience has shown the most economical equipment is moving the minimum amount of hydraulic oil that is just sufficient to get the task done. The closed center systems with their variable displacement pump achieve the hydraulic powered movement needed while moving the minimum amount of oil..

The farm tractor Open Center hydraulic system is constantly moving oil from the tank to the pump, from the pump to the cylinder or motor and then back. The volume of oil flowing is only controlled by the speed of the engine. The pump is a fixed displacement pump and each revolution of the pump must move a fixed quantity of hydraulic oil.

Hydraulics is all about flow and pressure. In an Open Center system, if you plumb another cylinder in parallel with an existing one by using Tee's off the main pressure line, the flow of fluid will take the easiest path back to the Tank. With a Tee, you are giving the fluid a choice of which way to go and it will always take the path that avoids building up pressure . This means the new cylinder if it is the one you want to move will not have any pressure as the fluid is using the parallel Tee to avoid the task you want performed.

I am going to suggest a number of youtube videos as they will do a far better job of increasing your knowledge than what I could give you by typing.

Here is the first one.

Keep asking questions!!

Hydraulic video

Dave

Thanks for the information and the Video.... We drew up a hydraulic diagram at work with it in parallel and I have a much better understanding of why it would not work now. I do have another question . Do you know where item number 3 on the included pic (oil return fitting) goes on the transmission case?I will gladly try to increase your knowledge of these two types of systems.

To start with try and use the terms Open Center and Closed Center .with the closed center being the parallel one your work mates speak of and use.

The parallel system is the most sophisticated one which offers the most precision in performance. You will have seen backhoe or excavator operators able to gently pick up a man and lower him into an excavation. Certainly contrary to safety regulations but it happens every day. Why does it happen..... workers feel safe and protected standing in a bucket. It is like being moved by the Gentle Giant some of us young kids knew as a TV character. The motion is slow and smooth.

If you are running large excavators 24 hours a day in a mining operation, the cost of the fuel you use is an important component of the cost equations which determine if you are making or loosing money. Experience has shown the most economical equipment is moving the minimum amount of hydraulic oil that is just sufficient to get the task done. The closed center systems with their variable displacement pump achieve the hydraulic powered movement needed while moving the minimum amount of oil..

The farm tractor Open Center hydraulic system is constantly moving oil from the tank to the pump, from the pump to the cylinder or motor and then back. The volume of oil flowing is only controlled by the speed of the engine. The pump is a fixed displacement pump and each revolution of the pump must move a fixed quantity of hydraulic oil.

Hydraulics is all about flow and pressure. In an Open Center system, if you plumb another cylinder in parallel with an existing one by using Tee's off the main pressure line, the flow of fluid will take the easiest path back to the Tank. With a Tee, you are giving the fluid a choice of which way to go and it will always take the path that avoids building up pressure . This means the new cylinder if it is the one you want to move will not have any pressure as the fluid is using the parallel Tee to avoid the task you want performed.

I am going to suggest a number of youtube videos as they will do a far better job of increasing your knowledge than what I could give you by typing.

Here is the first one.

Keep asking questions!!

Hydraulic video

Dave

Attachments

-

186.3 KB Views: 115

I understand why I need it and I know the other end hooks to the valve but I am not sure where this should be installed. I figure it will have to be tapped into the trans housing somewhere.Thanks for the information and the Video.... We drew up a hydraulic diagram at work with it in parallel and I have a much better understanding of why it would not work now. I do have another question . Do you know where item number 3 on the included pic (oil return fitting) goes on the transmission case?

Could you send me a picture of where the oil return line goes in the transmission?I did exactly what you are thinking of when I built my FEL:

The hydraulic block, as delivered:

Old cover removed:

New cover created by drilling and tapping a suitable block of steel (aluminium would probably be fine too) as per the dimensions in the manual, like so. Inside (left) and outside (right) of block shown). I tapped mine for 3/4" NPT. I tapped an extra hole, for possible future use or a gauge, on the outside face, and plugged the unused hole with a pipe plug. (The extra block went to another forum member who was also adding a FEL.)

Could you post a pic of where the oil return line goes on the transmission?I did exactly what you are thinking of when I built my FEL:

The hydraulic block, as delivered:

Old cover removed:

New cover created by drilling and tapping a suitable block of steel (aluminium would probably be fine too) as per the dimensions in the manual, like so. Inside (left) and outside (right) of block shown). I tapped mine for 3/4" NPT. I tapped an extra hole, for possible future use or a gauge, on the outside face, and plugged the unused hole with a pipe plug. (The extra block went to another forum member who was also adding a FEL.)

Never mind I figured it out. But thanks for the info and pics.Could you send me a picture of where the oil return line goes in the transmission?

Could you post a pic of where the oil return line goes on the transmission?

I understand why I need it and I know the other end hooks to the valve but I am not sure where this should be installed. I figure it will have to be tapped into the trans housing somewhere.

I figured it out. Thanks again.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

If you figured out that you need a short 1/2" pipe nipple and tee to connect the return line to the fill hole, then you get a gold star! ;-)

Well I got it all done. I bought the 2 spool Prince valve. It seems to all work good except when raising the loader and I let off the lever and it returns to center it will drop about an inch. If the loader is up and I bring it down and let the lever return to center it sometimes keeps going after the valve is back to center. Any ideas of what's going on?I personally helped a friend install a FEL on a B7100. This was years ago but some details are firmly fixed in my mind.

I wish we had the details including part numbers which Whitetiger has provided you.

The B7100 WSM, available free on Kubotabooks.com, has an excellent color illustration of how the new outlet block cover is to be connected to a new valve. Presently, the B7100's only hydraulic system pressure relief valve is at the 3 pt hitch end of the tractor.

Kubotabooks.com

Using the new outlet block cover to install a loader valve between the main pump and the rear of the tractor cuts the only pressure relief valve out of the circuit and exposes the main pump to severe damage.

The new loader valve must have its own pressure relief valve. Most new valves do but it is a critical part of a successful installation.

In this illustration the relief valve marked with a green box is exterior to the new valve but this is just for explanatory purposes.

View attachment 59965

A common mistake owners make when buying a loader valve is to buy the one with the most gpm rating. This is the opposite of what you want to do and will make controlling your loader very difficult.

The B7100 has a gpm rating of almost 3 gpm which is small.

Recently a forum member was installing a new loader valve. He made a decision which will be valuable in the future. His new valve had the two common spools controlled by a joystick but as part of the same valve body was a third spool controlled by an individual lever. This third spool was provided to control a future grapple.

Most hydraulic valves are not designed to tolerate high pressures on their TANK port. You should be using a power beyond port for the oil being fed from the new loader valve back into the hydraulic system going to the rear of the tractor. PB is usually a $25 option you need to buy when you buy your new valve..

This is the 3 spool valve the B2400 owner had ordered.

3 spool valve

These are images of the PB sleeve. They are unique for a particular series of valves in this case a Badestnost 40 series.

A plug in the new valve body is removed and the PB sleeve is screwed in. The sleeve creates an additional port on the valve body.

View attachment 59967

Forum member Win22wrf, who has a B7100, has suggested this 8 gpm valve in the past.

Prince valve

If at any time during your project you are uncertain, dont try something to see if it will work. This is not a good strategy with hydraulics. come back with questions until you know exactly what you need to do.

Dave