Hi there. So I have this L3450DT-7 tractor I've been tinkering with for a year or so and finally have it ready to take home and start using. It had some really bad hydraulic leaks originally when I got it and those are now fixed. Yesterday I added a gallon of hydraulic oil at the fill port behind the seat knowing it was low but not knowing exactly how low, so I could drive it to the shop I'm at now. Everything was fine thinking I can now put the loader back on, button things up, get the oil levels right and take it home for good this afternoon. So it had a puddle under the oil pan when I came in this morning and oil coming from engine dipstick. Pulled the dipstick and oil starts gushing out. What the heck? How could that gallon of hydraulic oil I added above the rear axle have possibly got in the crankcase? I didn't EVEN want to try to figure this out without asking Kubota people first. Thank's.

Hydraulic oil in engine oil pan? What?

- Thread starter Sawzall

- Start date

Leaking shaft seal on the engine driven hydraulic pump. Spews hydraulic fluid right into the crankcase.

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

Well all right then. Went out and looks pretty straight forward. Is the anything particular I should watch out for so I do it right the first time?

I looked at parts blowup on Messicks website. It looks like the shaft seal at the 2 bolt flange on the pump. Part #31381-76390? Thanks a lot I would of never figured that out.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

There are a few o-rings involved that can be replaced while you take it apart. There are also some square rings that can also be replaced. These rubber parts are all probably fine to reuse but also (probably) cheap enough to replace.Well all right then. Went out and looks pretty straight forward. Is the anything particular I should watch out for so I do it right the first time?

Buy a quart of the transmission fluid or use clean fluid you already have to use for lubricating the parts as you assemble them.

Clean the exterior of the pump well before you remove it from the tractor. Put something in or over the opening in the tractor that was covered by the pump. Clean the pump again before you start to disassemble the pump. Use clean disposable aluminum pans to work in and keep parts clean in. Use some clean rags and clean disposable gloves to do the work and try to keep the pump as clean and dust free as possible. Cover the pans to keep the parts fairly clean. You should know how much torque to put on the bolts since they are small and can easily be twisted off. Don’t be a gorilla or you will regret it.

Before you install the pump or before you install the top outlet fitting try to get (pour) fluid into the pump so it is wet and will be lubed when you start the tractor.

Change the engine oil and filter before you use the tractor.

It only takes a few minutes to do unless the seal you get doesn’t fit. Then days of waiting for the part can occur. Don’t be overly concerned about doing it but don’t damage the seal as you install it. There is probably some circlip involved so you may need to get a set of pliers to remove it, don’t try using just whatever you have!

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Something has to be wrong for it to blow that seal!

These are not know for leaking like older models.

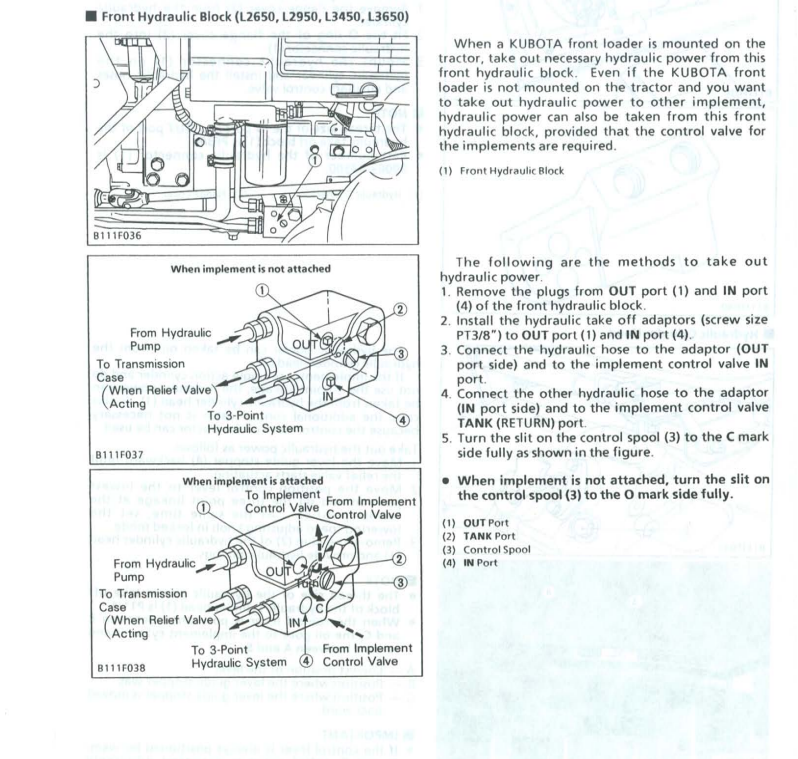

Did you turn the selector switch on the hydraulic block with the loader being off, or have the lines looped together.

If not that's the reason you blew the seal.

These are not know for leaking like older models.

Did you turn the selector switch on the hydraulic block with the loader being off, or have the lines looped together.

If not that's the reason you blew the seal.

Selector switch? Hydraulic block? Sorry but this is my first Kubota and learning what makes what happen. No stickers remaining and any instructions or identification on any knobs are long wore off. The only blocks I'm aware of are the block where I disconnected the loader hoses to remove the loader [which also disabled the 3 point], and it doesn't have any kind of selector and then the block and restrictor wheel under the seat. I turned it all the way left and right and put it in the middle for now. It was all the way counterclockwise when the seal blew.Something has to be wrong for it to blow that seal!

These are not know for leaking like older models.

Did you turn the selector switch on the hydraulic block with the loader being off, or have the lines looped together.

If not that's the reason you blew the seal.

Anyway, so I replaced the seal, replaced the leaking pto shaft seal and replaced one of the seals on the steering cylinder. Changed engine oil and filter, added 5 gallons universal tractor fluid at fill port behind seat. Would be nice to know where to check the full level to make sure it's properly filled but I'm not finding anything period. Dipstick, removable level fill plug or the elusive supposed sight glass i've read about. Anyway I fired it up and no hydraulic pressure. Of course with loader off and 3 point disabled the only thing left is steering and there is absolutely nothing. Am I just low on fluid or should I have prefilled something? Or is there like a bleed point? Airlock? Thanks a lot and sorry for all the questions at once. This really can't be that difficult

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

You don't have the selector valve on the hydraulic block in the proper setting.

Hence the reason you have blown the seal and have no hydraulics as you are dead heading the system.

Operate the three point and the steering to purge air out of the system after change the selector valve to be in the Loader Removed position.

In all your fluid swapping did you change the hydraulic filter?

Might want to do that, as running it low on hydraulic fluid sucks all the junk in the sump into the filter.

Pages M.9-21 and M.9-22 in the WSM aka Service manual

Page 26 of the OPS aka operators manual

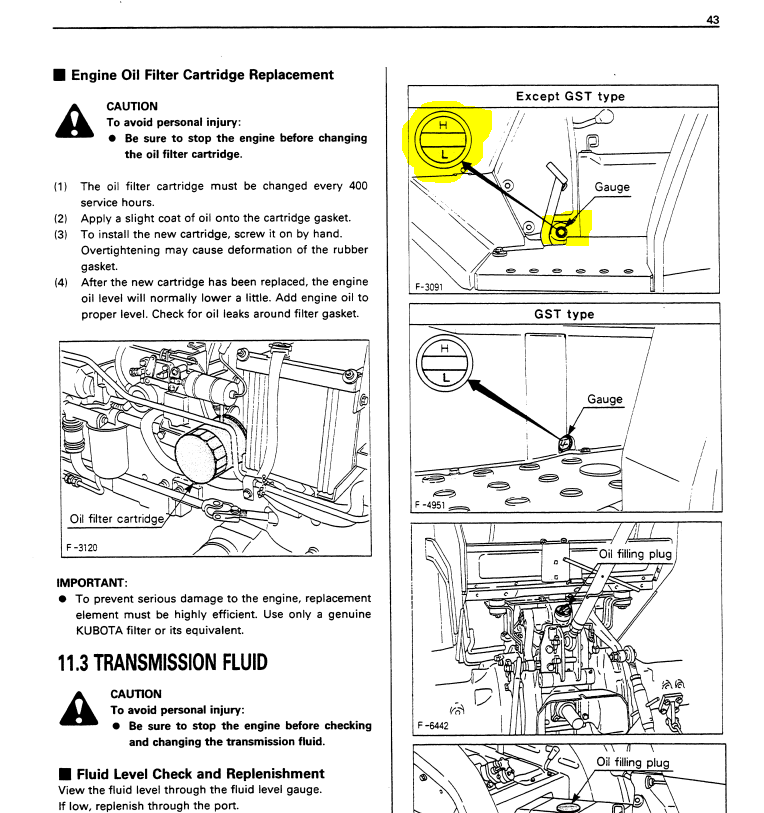

Over filling or underfilling hydraulic oil can cause all sorts of issues like blow and leaking seals.

If you have it over filled you will not be able to tell, as the whole gauge will be under fluid.

Page 43 of the OPS

Hence the reason you have blown the seal and have no hydraulics as you are dead heading the system.

Operate the three point and the steering to purge air out of the system after change the selector valve to be in the Loader Removed position.

In all your fluid swapping did you change the hydraulic filter?

Might want to do that, as running it low on hydraulic fluid sucks all the junk in the sump into the filter.

Pages M.9-21 and M.9-22 in the WSM aka Service manual

Page 26 of the OPS aka operators manual

Over filling or underfilling hydraulic oil can cause all sorts of issues like blow and leaking seals.

If you have it over filled you will not be able to tell, as the whole gauge will be under fluid.

Page 43 of the OPS

IT WORKS! Thanks so much. Other than it blew out the other side steering cylinder seal.. I knew I should have replaced both. But after doing one side it's actually pretty quick and simple. Now we'll get into the other stuff that's getting ready to pop once I put it to work.This is some awesome info. Thank's, I'll get into this after work

One more question, so the transmission and rear filler port share the same fluid and sight glass? What’s reason for 2 fill ports? I’m old school fords and masseys. 1 fill port on transmission only.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

It was because different model and sizes that shared the same parts were equipped different ways, they had multiples so they can get access to one or the other port when something like a cab is installed.One more question, so the transmission and rear filler port share the same fluid and sight glass? What’s reason for 2 fill ports? I’m old school fords and masseys. 1 fill port on transmission only.

The motor is the same way some have as many as three fill points.

You don't have the selector valve on the hydraulic block in the proper setting.

Hence the reason you have blown the seal and have no hydraulics as you are dead heading the system.

Operate the three point and the steering to purge air out of the system after change the selector valve to be in the Loader Removed position.

In all your fluid swapping did you change the hydraulic filter?

Might want to do that, as running it low on hydraulic fluid sucks all the junk in the sump into the filter.

Pages M.9-21 and M.9-22 in the WSM aka Service manual

Page 26 of the OPS aka operators manual

View attachment 125917

Over filling or underfilling hydraulic oil can cause all sorts of issues like blow and leaking seals.

If you have it over filled you will not be able to tell, as the whole gauge will be under fluid.

Page 43 of the OPS

View attachment 125918

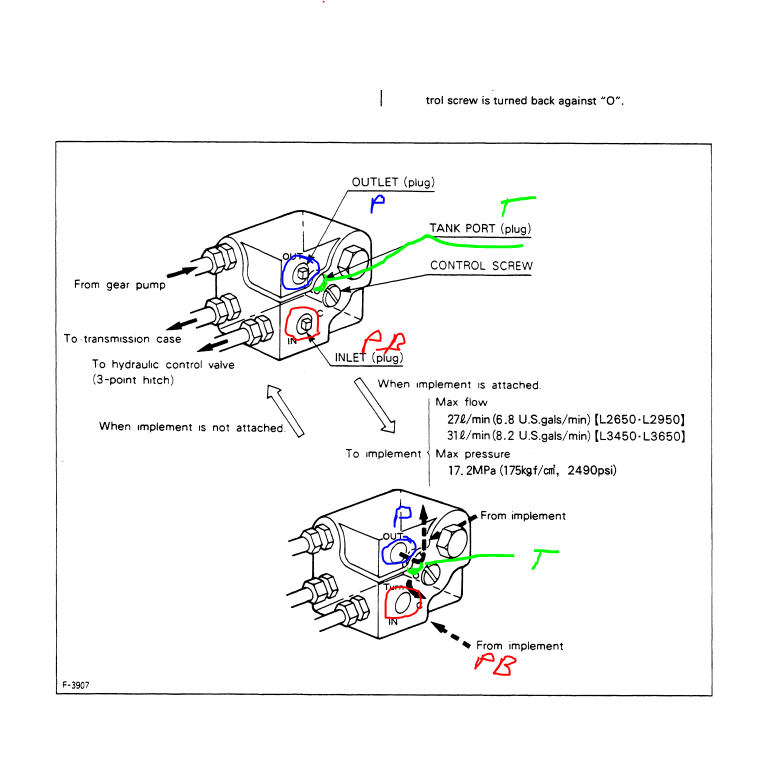

Wolfman can we go back to the hydraulic block diagram for a minute? I've attached the loader with a new valve. Not exact confirmation but with same features. And I have turned the selector screw. It's doing some weird things. Bucket curl and steering works fine but loader lift and 3 point won't work unless I do them together. It has the power beyond and diagram doesn't show that port. So, I've got the out from the block to the input on the valve and I'm sure that's correct. I've got the out from the valve connected to the in [lower port} on the block. Just like the diagram. Now comes the power beyond hose. From the valve i've got that hose connected to the front port on the block which is not shown in the diagram. These are the same 3 ports the original valve was using. I'm wondering if I should switch the front power beyond hose with the block in port hose? The power beyond hose flexes when I try to lift the loader but loader won't lift unless I also lift the 3 point.You don't have the selector valve on the hydraulic block in the proper setting.

Hence the reason you have blown the seal and have no hydraulics as you are dead heading the system.

Operate the three point and the steering to purge air out of the system after change the selector valve to be in the Loader Removed position.

In all your fluid swapping did you change the hydraulic filter?

Might want to do that, as running it low on hydraulic fluid sucks all the junk in the sump into the filter.

Pages M.9-21 and M.9-22 in the WSM aka Service manual

Page 26 of the OPS aka operators manual

View attachment 125917

Over filling or underfilling hydraulic oil can cause all sorts of issues like blow and leaking seals.

If you have it over filled you will not be able to tell, as the whole gauge will be under fluid.

Page 43 of the OPS

View attachment 125918

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Front / bottom is the tank port.

Top face is power

Bottom face is PB

Sounds like you have PB and T swapped

Top face is power

Bottom face is PB

Sounds like you have PB and T swapped

Ok fellas that definately helped and everything is working in the correct order but.....The loader lift has very little power. 3 point is strong and curl is strong. I have to really up the rpm's to get it to lift past halfway and it will go all the way up. I can shut it off and lift will stay up overnight no problem. Would this be just one of the lift cylinders bypassing? It has none to little down pressure also. Lets say I have it half way up. I can pull back a little and it will drop but if I pull all the way back and rev it up it will lift. Shouldn't be able to go down at all in the lift position right? Shame is this is the problem I had before I went through the time and expense of a new valve. Thanks.Front / bottom is the tank port.

Top face is power

Bottom face is PB

Sounds like you have PB and T swapped

View attachment 127457