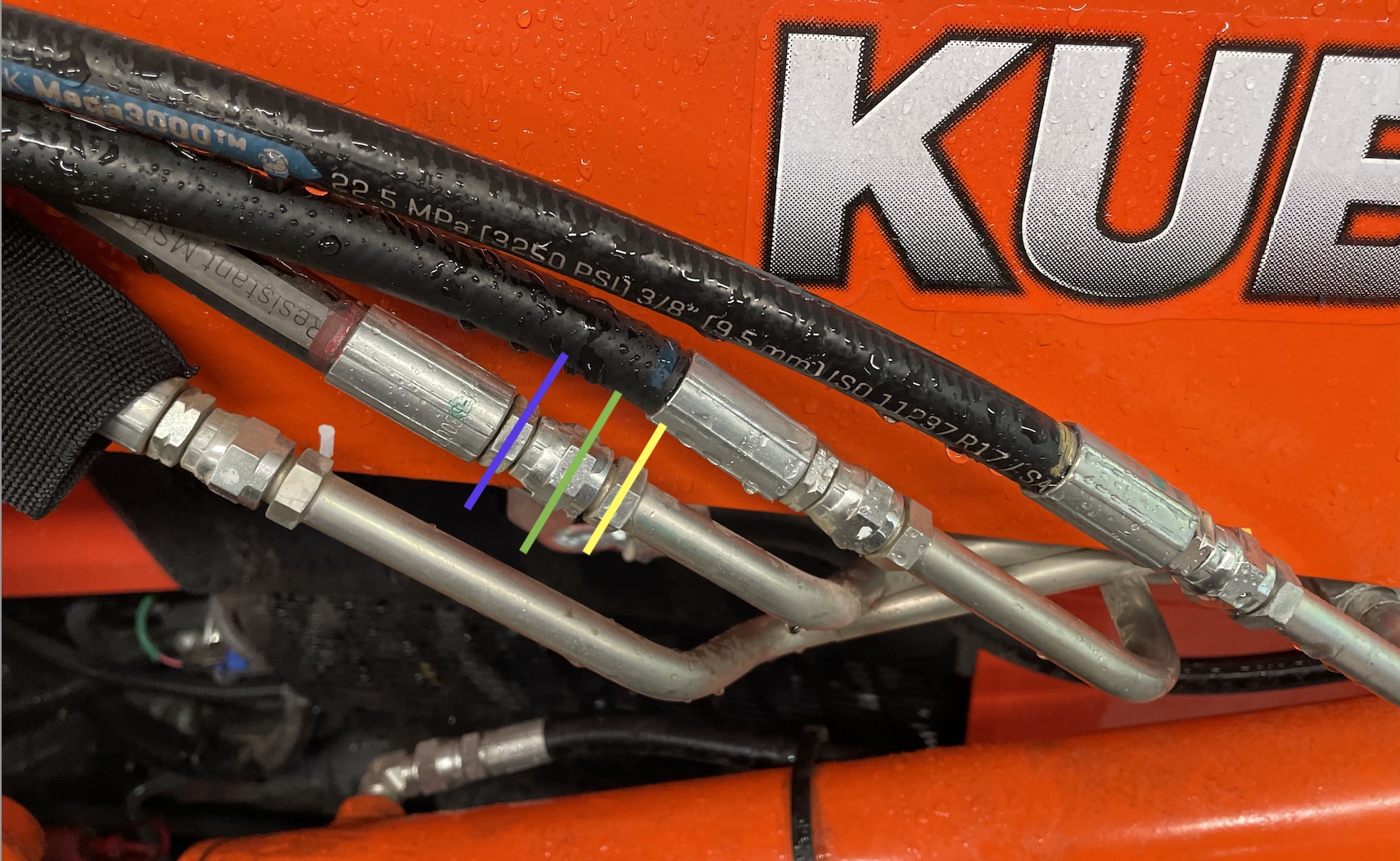

Embarrassing question and I really don't want to break these hard lines on the loader - I overlayed three different colored lines on each of what I believe are wrench points at the connection from soft to hard lines.

My questions:

Which line (purple, green, yellow) is the hold spot, and which line do I need to twist and in what direction to disconnect these fittings?

My guess would be: hold yellow line with wrench, twist green line with wrench counter-clockwise/basically toward the top of the loader.

Reason behind my question is it's unclear to me whether the spinning center nut is part of the soft hose or the hard line?

If I turn tractor off, 360 the joystick, and disconnect the quick couplings from the tractor these loader lines should not be pressurized correct?

Thank you

My questions:

Which line (purple, green, yellow) is the hold spot, and which line do I need to twist and in what direction to disconnect these fittings?

My guess would be: hold yellow line with wrench, twist green line with wrench counter-clockwise/basically toward the top of the loader.

Reason behind my question is it's unclear to me whether the spinning center nut is part of the soft hose or the hard line?

If I turn tractor off, 360 the joystick, and disconnect the quick couplings from the tractor these loader lines should not be pressurized correct?

Thank you