So I started off looking for a B7100 in the NW (I am in Portland). I placed an ad in the classifieds on this forum and received several helpful replies. I followed Craigslist for a few weeks and got an idea of what people were asking and what they were going for in various conditions. Then I came upon a "fixer". I have a knack for dragging home injured vehicles like a kid who falls in love with a free kitten. So what did I get?

Newer model B7100 HST - the frame is dark grey and the engine still has fresh paint and factory decals.

Aftermarket quick release Westendorf TA-55 loader.

"Frozen engine"

As I have embarked on my journey of diagnosis (Tractortopsy) I have discovered a laundry list of problems. And before saying more, I would like to thank all of the folks who offer expertise and share their experiences on this forum because I have learned an awful lot. I know what many of these problems are and now have some idea of how to tackle them. There are individual threads describing many if not all of these problems but I'll make a laundry list of sorts. Feel free to offer advise on any or all of them.

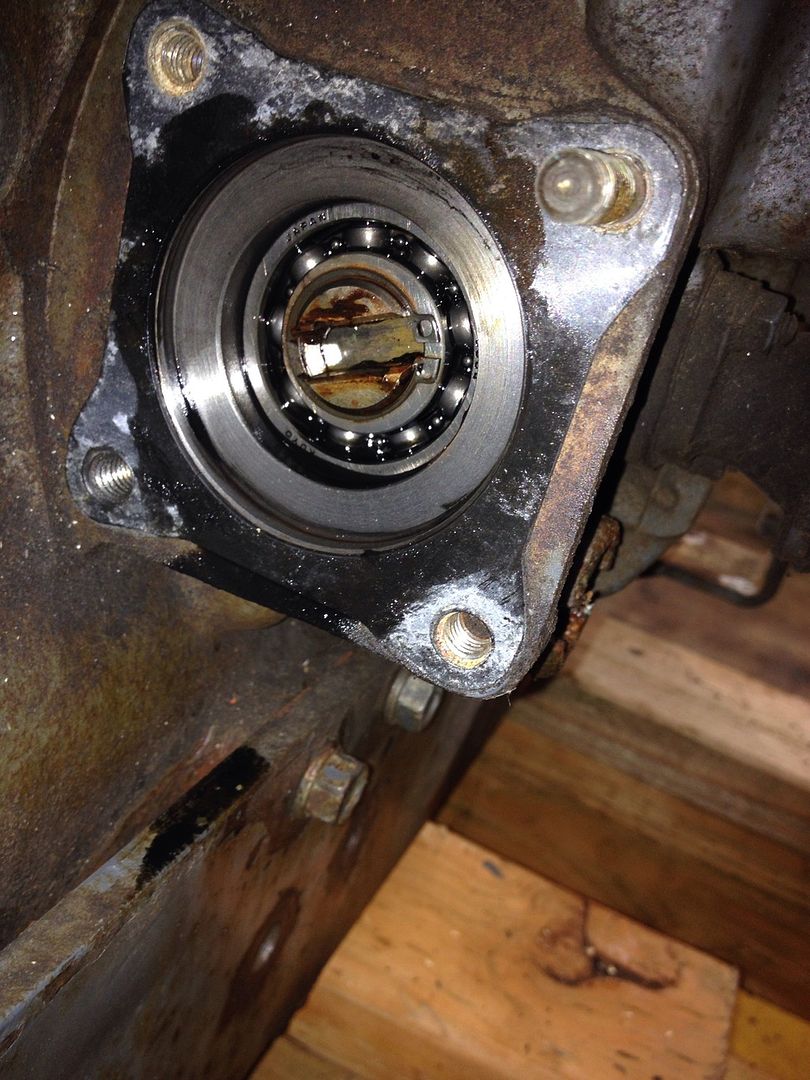

1) Frozen engine turns out to be shattered clutch. Looking at the damage and after studying past posts regarding pilot bushings, clutch failure etc, it appears that someone replaced the clutch in this tractor without replacing the pilot bushing. The crankshaft hole is slightly enlarged and the drive shaft slightly damaged. I have read threads where people have removed the crank shaft, machined the original hole and installed a larger bushing. Others have bored out the flywheel and inserted a bushing there. Some people have found that their pilot bushing is much larger than the factory part - probably because someone made this repair prior to them purchasing their tractor. I'm leaning toward machining the crankshaft and if all looks good in the pan, reusing the bearings. That way I can still use a seal to keep dust and grime out of the pilot bushing. The flywheel route would be much less work. I'm curious how these two approaches have held up. The splined drive shaft is banged up where it inserts into the crankshaft. If anyone has one in good condition, please let me know.

2) The front frame member was cracked allowing the front axle to move fore and aft. The previous owner made a feeble attempt to weld it - the gap was huge and the weld was like bubble gum. I already purchased a replacement from a tractor junkyard.

3) The movement of the axle resulted in two pretty large gashes in the front of the oil pan. Still intact but it dug in enough that I would like to find a replacement. Anyone have an oil pan from a dead engine that they would part with?

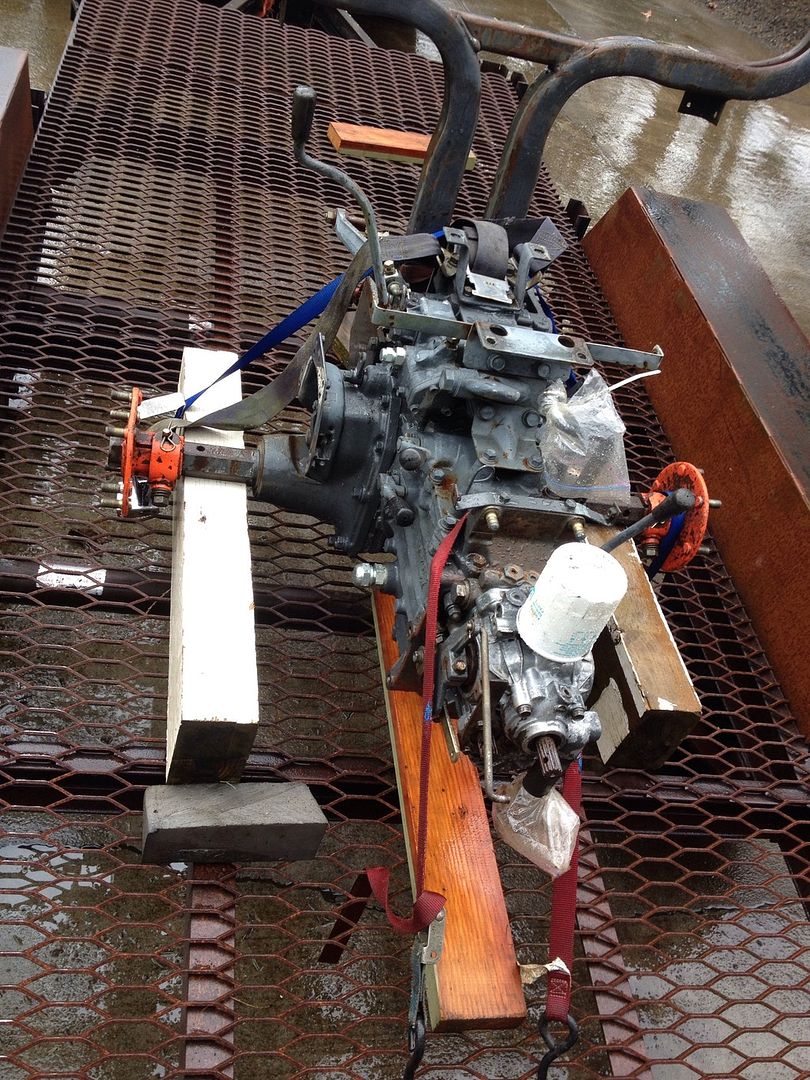

4) The rear frame member is cracked. There are stress cracks toward the rear three accessory mounting holes on each side - these are not so bad. I planned to weld them up. The bell housing is cracked at the top rim. I figure this is related to the clutch failure. This bit looks weldable too. The final blow is that there are cracks on both FEL mounting brackets. The face of the brackets are cracked. I'm not sure but it looks like someone modified the FEL mounting bracket and it may be inadequately supported. That or it was just used and abused. The junk yard has rear frames but only for geared B7100's. If anyone has a dead B7100HST with an intact rear frame, I would be happy to take it off your hands. I was ok with welding this frame until I found the cracks in the loader mounting brackets. Those are hard to live with and I'm not so sure my welded repair will be as strong as it needs to be. Really hard to get to the back side of the damaged pieces. Additionally, if anyone has a picture of a TA-55 is mounted to a B7100, it would be really helpful to get an idea if I am missing some mounting parts.

Well, there you have it. I can post some more pictures if anyone is interested. I find the age of the tractor curious because it has the dark grey frame paint. I think the orange is the early orange but haven't confirmed that. A dealer thought it was from 2002 but I am not sure they were selling these units after about 1999 from what I have read. It doesn't seem that the serial numbers are particularly helpful to sort out the age of a B7100.

I know this post reads kind of like a bad country song. The good news is that my girl hasn't left me and my dog is still alive.

Thanks again to the folks who post on Orange Tractor Talks. Any advice is welcome.

Newer model B7100 HST - the frame is dark grey and the engine still has fresh paint and factory decals.

Aftermarket quick release Westendorf TA-55 loader.

"Frozen engine"

As I have embarked on my journey of diagnosis (Tractortopsy) I have discovered a laundry list of problems. And before saying more, I would like to thank all of the folks who offer expertise and share their experiences on this forum because I have learned an awful lot. I know what many of these problems are and now have some idea of how to tackle them. There are individual threads describing many if not all of these problems but I'll make a laundry list of sorts. Feel free to offer advise on any or all of them.

1) Frozen engine turns out to be shattered clutch. Looking at the damage and after studying past posts regarding pilot bushings, clutch failure etc, it appears that someone replaced the clutch in this tractor without replacing the pilot bushing. The crankshaft hole is slightly enlarged and the drive shaft slightly damaged. I have read threads where people have removed the crank shaft, machined the original hole and installed a larger bushing. Others have bored out the flywheel and inserted a bushing there. Some people have found that their pilot bushing is much larger than the factory part - probably because someone made this repair prior to them purchasing their tractor. I'm leaning toward machining the crankshaft and if all looks good in the pan, reusing the bearings. That way I can still use a seal to keep dust and grime out of the pilot bushing. The flywheel route would be much less work. I'm curious how these two approaches have held up. The splined drive shaft is banged up where it inserts into the crankshaft. If anyone has one in good condition, please let me know.

2) The front frame member was cracked allowing the front axle to move fore and aft. The previous owner made a feeble attempt to weld it - the gap was huge and the weld was like bubble gum. I already purchased a replacement from a tractor junkyard.

3) The movement of the axle resulted in two pretty large gashes in the front of the oil pan. Still intact but it dug in enough that I would like to find a replacement. Anyone have an oil pan from a dead engine that they would part with?

4) The rear frame member is cracked. There are stress cracks toward the rear three accessory mounting holes on each side - these are not so bad. I planned to weld them up. The bell housing is cracked at the top rim. I figure this is related to the clutch failure. This bit looks weldable too. The final blow is that there are cracks on both FEL mounting brackets. The face of the brackets are cracked. I'm not sure but it looks like someone modified the FEL mounting bracket and it may be inadequately supported. That or it was just used and abused. The junk yard has rear frames but only for geared B7100's. If anyone has a dead B7100HST with an intact rear frame, I would be happy to take it off your hands. I was ok with welding this frame until I found the cracks in the loader mounting brackets. Those are hard to live with and I'm not so sure my welded repair will be as strong as it needs to be. Really hard to get to the back side of the damaged pieces. Additionally, if anyone has a picture of a TA-55 is mounted to a B7100, it would be really helpful to get an idea if I am missing some mounting parts.

Well, there you have it. I can post some more pictures if anyone is interested. I find the age of the tractor curious because it has the dark grey frame paint. I think the orange is the early orange but haven't confirmed that. A dealer thought it was from 2002 but I am not sure they were selling these units after about 1999 from what I have read. It doesn't seem that the serial numbers are particularly helpful to sort out the age of a B7100.

I know this post reads kind of like a bad country song. The good news is that my girl hasn't left me and my dog is still alive.

Thanks again to the folks who post on Orange Tractor Talks. Any advice is welcome.