B6100e wet lines ??

- Thread starter Farmb0y

- Start date

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

I would think something on the order of $25 should cover my expenses -- a block of steel, and a little something towards the consumables like hydro, cutting oil, and tool wear. If the forecast is right and it rains all day I might even get to it tomorrow.

(I'll be needing mine soon too. I'm almost to the point of mounting the arms and cylinders.)

(I'll be needing mine soon too. I'm almost to the point of mounting the arms and cylinders.)

Keep us posted with pics also torch, I'm very curious on this.

Sent from my SM-G930T using Tapatalk

Sent from my SM-G930T using Tapatalk

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Pics of what, exactly? The machining process? I posted the drawing from the WSM earlier in this thread.Keep us posted with pics also torch, I'm very curious on this.

Oh well, here's where we are at as of last night:

I'm away for the weekend, so that's as far as it will go until Monday. I'll square up the second block and start drilling some holes as per the drawing. Not particularly exciting, IMHO.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

90% certain. I think the parcel has to be under 5kg to qualify. I haven't weighed the chunk of steel but it can't be anywhere close to 5kg -- I doubt it's 5 lbs. And it has to be mailed on a Tuesday in October. But I think I can send one each Tuesday in October.And you are sure of the shipping g cost will be nil too ?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

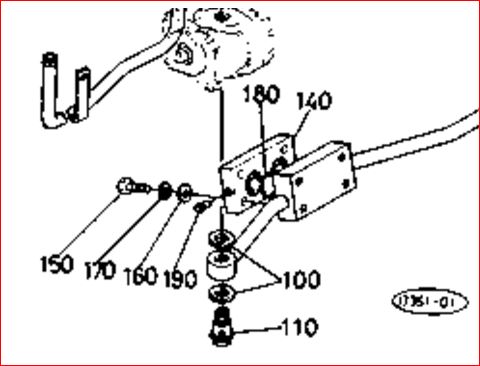

The diagram in the WSM does not specify thickness or the outlet thread. By proportion, the thread appears to be approximately 1/4" tapered pipe thread. Could be BSP (common with Japanese stuff) or NPT.

Looking at the diameter of the incoming pressure line and the diameter of the passage inside the block, I'm thinking of making them 3/8" NPT (based on the B319 hose size specified in that manual). Does anyone know a reason I should not do so?

Looking at the diameter of the incoming pressure line and the diameter of the passage inside the block, I'm thinking of making them 3/8" NPT (based on the B319 hose size specified in that manual). Does anyone know a reason I should not do so?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Well, I got the second block prepared and was just about to polish the mating surfaces with my poor man's surface grinder when the power went out due to the storm we are currently experiencing. So now I don't know if I'll get it done in time to ship tomorrow after all. Arrrrgh.

Oh well, here is how far I got:

Oh well, here is how far I got:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The stock block's were 3/8 BSPP O-ring Boss fittings, but you would be better off using NPT as they just use adapters on the others anyways.

Did you cut indents in the joint side for the seal O-rings?

Did you cut indents in the joint side for the seal O-rings?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Ok, 3/8" NPT it is.The stock block's were 3/8 BSPP O-ring Boss fittings, but you would be better off using NPT as they just use adapters on the others anyways.

No, according to the WSM drawing the o-ring grooves are cut on the tractor half and the hydraulic block half is to be flush.Did you cut indents in the joint side for the seal O-rings?

(probably should fit new o-rings when the block is installed though).

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

You might be right, I don't remember fr sure but I thought it did, just going off of a bad memory.

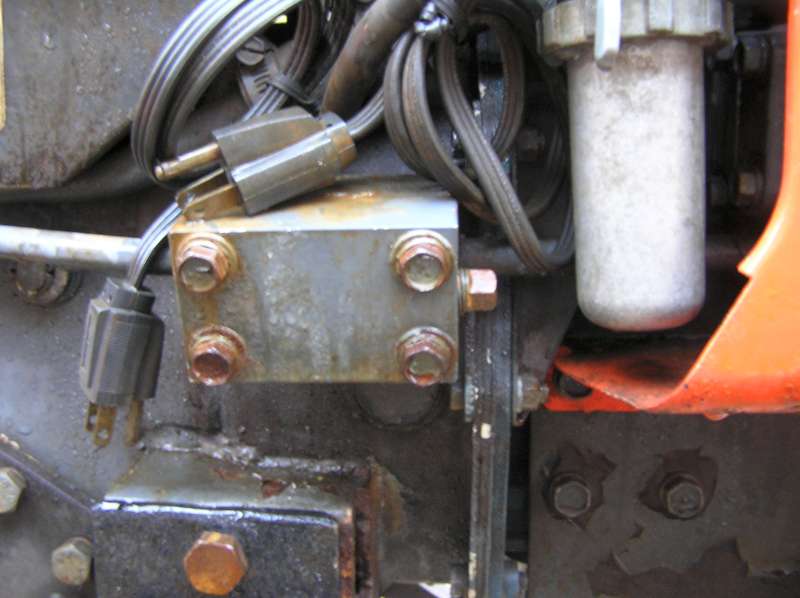

But look at this picture.

But look at this picture.

Attachments

-

34 KB Views: 586

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Hmmm. That drawing certainly makes it look like the o-rings could be in the hydraulic block side. I guess I better pop mine off and visually confirm before I send this off to farmboy.But look at this picture.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Time to call it a night, I'm starting to fade. Don't want to make any stupid mistakes at this point!

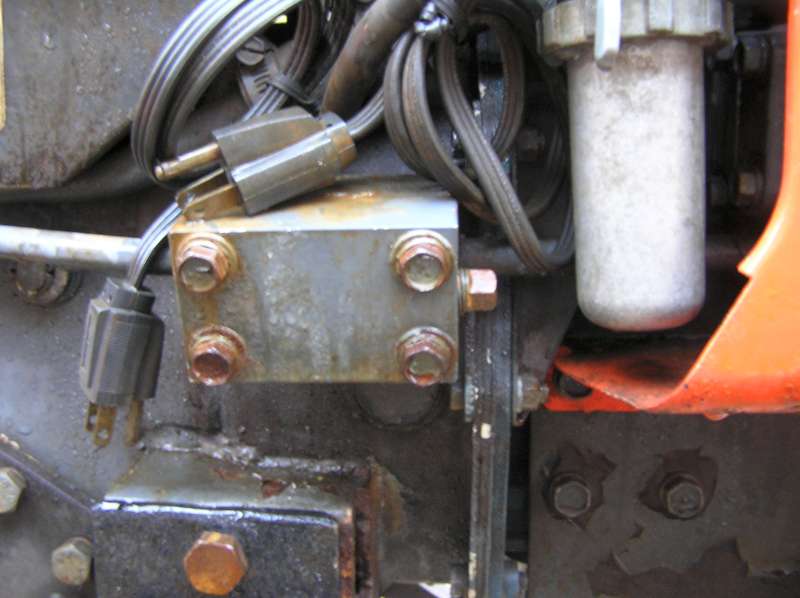

Got the holes drilled, getting ready to tap:

Got the holes drilled, getting ready to tap:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Why did you drill in the side?

You don't want the 2 posts connected, that's what the original block does.

Or did you drill half way threw on the back and the side, so that both sides come out the sides instead of the face?

You don't want the 2 posts connected, that's what the original block does.

Or did you drill half way threw on the back and the side, so that both sides come out the sides instead of the face?

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Yes, the ports are not connected, they just make another 90° bend. That's how the WSM diagram shows it, so that's how I did it:Or did you drill half way threw on the back and the side, so that both sides come out the sides instead of the face?

It would have been simpler and easier to just drill the ports straight through but I suppose the factory configuration does have the advantage of keeping the hoses tucked in close to the tractor. Other options would be to bring them out the top, or the bottom, or one of each. Heck, one could do them all and plug the unused ports!

EDIT: Wrong. Top and bottom are not options with 3/8" ports. There is insufficient clearance. The threads would break out into the mounting bolt holes. See my next post for more detail.

So long as a) the ports are not connected and b) the hole in the mating surface does not exceed the o-ring diameter, there is no "wrong" way. I just didn't bother getting that creative.

Last edited:

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

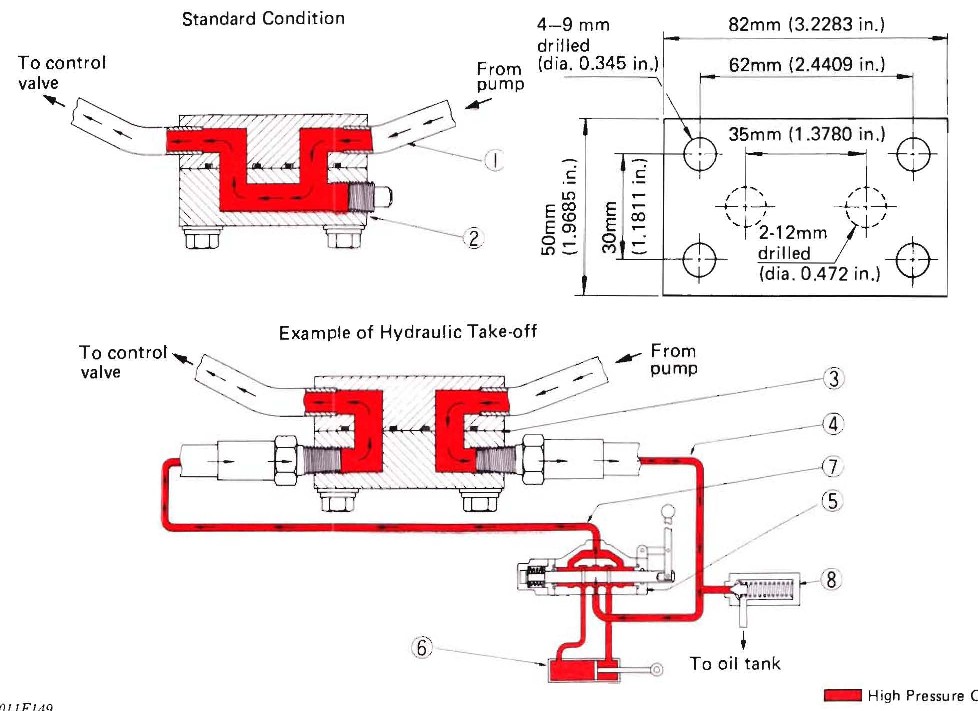

Ok, short story: Done. One for me, one for farmbOy and his is on the way. Here's a shot of the tapping process, just for completeness:

Now, longer story:

As discussed last night, I removed the existing cover to check the o-rings. When you get right down at eye level with it, there's not really a lot of clearance between the block and the filter housing. It would probably work, but accessing the filter in the future would be a bit of a PITA:

So I decided to add a third port. Despite what I said last night, the top or bottom are NOT an option -- at least, not for a 3/8" hole. There is not enough clearance between the mounting bolt holes and the port. I'll go back and edit last night's comments in a minute.

I did have enough meat to add a port on the outside face, but only because I made the new block 30mm thick. Any thinner and there would not be sufficient thickness to thread -- well, you could, but it's the end 3 threads that seal against leakage, and they would be cut off in thinner material.

The existing cover is 25mm thick with a 1/4" plug in the end. The drawing does not specify the thickness of the new cover, so I made it a bit thicker, just because that's what I had and I didn't feel like milling off another 5mm.

So there are 3 ports, one of which will have to be plugged with a 3/8" pipe plug (not included). But it's more flexible than Kubota's version.

Anyway, back to the o-ring issue; the WSM drawing is correct, the parts diagram drawing is wrong:

And here is the finished result:

Now, longer story:

As discussed last night, I removed the existing cover to check the o-rings. When you get right down at eye level with it, there's not really a lot of clearance between the block and the filter housing. It would probably work, but accessing the filter in the future would be a bit of a PITA:

So I decided to add a third port. Despite what I said last night, the top or bottom are NOT an option -- at least, not for a 3/8" hole. There is not enough clearance between the mounting bolt holes and the port. I'll go back and edit last night's comments in a minute.

I did have enough meat to add a port on the outside face, but only because I made the new block 30mm thick. Any thinner and there would not be sufficient thickness to thread -- well, you could, but it's the end 3 threads that seal against leakage, and they would be cut off in thinner material.

The existing cover is 25mm thick with a 1/4" plug in the end. The drawing does not specify the thickness of the new cover, so I made it a bit thicker, just because that's what I had and I didn't feel like milling off another 5mm.

So there are 3 ports, one of which will have to be plugged with a 3/8" pipe plug (not included). But it's more flexible than Kubota's version.

Anyway, back to the o-ring issue; the WSM drawing is correct, the parts diagram drawing is wrong:

And here is the finished result:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Excellent, was just checking.

Yes clearance on these little guys is really tight, my stock block just has the ports coming out the front with 90 degree fittings, and none out the sides.

Yes clearance on these little guys is really tight, my stock block just has the ports coming out the front with 90 degree fittings, and none out the sides.