Hi All. I'm trying to find out how to remove the oil (nub, don't have a better name) from the block surface of my D650 so I can work on it. It directs oil from the block into the head for valve lubrication. Thanks!

B6100 oil nub removal from block

- Thread starter southernpiper1

- Start date

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Looks like a brass MIP (male iron pipe) to compression adapter. It should unthread by turning counter clockwise.

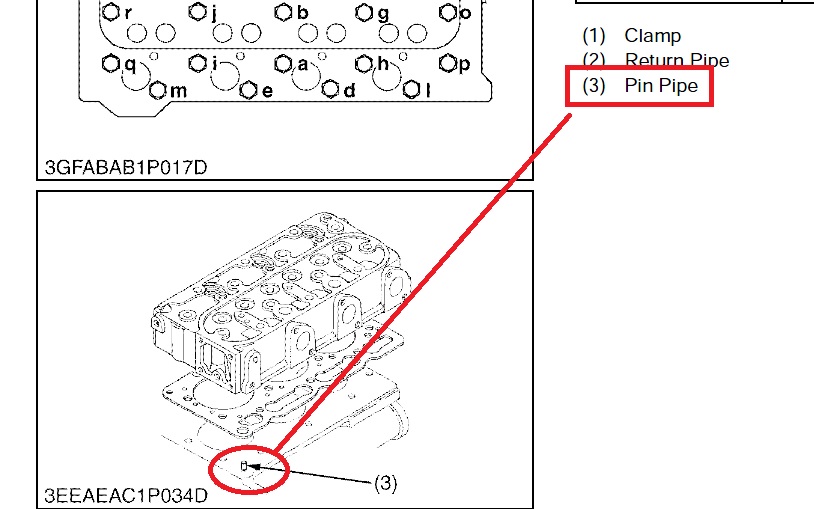

I think he is referring to the pin pipe in the top of the head.

I recall NIW discussing these pins a while back.

NIW said:.

That pin pipe moves oil from the block to the head for lubing the valve train.

Putting a dowel pin in place of it will destroy the top end.

Not putting a pin pipe in it will likely cause it to leak oil.

I think the pin is just dropped in like the dowels which locate the head.

Likely pull out with vice grips.

Dave

I recall NIW discussing these pins a while back.

NIW said:.

That pin pipe moves oil from the block to the head for lubing the valve train.

Putting a dowel pin in place of it will destroy the top end.

Not putting a pin pipe in it will likely cause it to leak oil.

I think the pin is just dropped in like the dowels which locate the head.

Likely pull out with vice grips.

Dave

Last edited:

10-4 locating hollow dowel pin. Should be a light press fit. If it don't want to come out with light persuasion, take a propane torch and lightly heat the surrounding area to expand it and it will come out.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Kinda tried that but thanks. This is the thing on top. Not the side and it seems to be steal. Didn't want to come and obviously it isn't rusted. Don't want to bugger it up. Anyone have any experience with this? You can't mill the block without taking it out or grinding it down.Looks like a brass MIP (male iron pipe) to compression adapter. It should unthread by turning counter clockwise.

Sidecar flip, thank you, missed your response initially. Sounds good I'll give it a try tonight. I think it will take the heating because it's a little stubborn.10-4 locating hollow dowel pin. Should be a light press fit. If it don't want to come out with light persuasion, take a propane torch and lightly heat the surrounding area to expand it and it will come out.

Thanks again.

A new pin pipe is only $3.50Sidecar flip, thank you, missed your response initially. Sounds good I'll give it a try tonight. I think it will take the heating because it's a little stubborn.

Thanks again.

Dave

Sounds like a pretty cheap date compared to other OEM parts.A new pin pipe is only $3.50

Dave

Pau7220

Well-known member

Equipment

L3650 GST, Landpride TL250 FEL w/ Piranha, 6' King Kutter, GM1084R Finish

When you say milling the block, you have this completely torn down for overhaul? I ask because the cast iron and silicon carbide dust I see on the pistons and in the pushrod bores from the sandpaper is concerning. Milling the deck may require a shim. NIW or lugbolt can offer more guidance on this.You can't mill the block without taking it out or grinding it down.

Whatever you do, don't grind it down. Has to be there are it feeds oil to your rocker arms.Kinda tried that but thanks. This is the thing on top. Not the side and it seems to be steal. Didn't want to come and obviously it isn't rusted. Don't want to bugger it up. Anyone have any experience with this? You can't mill the block without taking it out or grinding it down.

Thanks, I did figure that but certainly better to be safe. With a little work, I removed it.Whatever you do, don't grind it down. Has to be there are it feeds oil to your rocker arms.

Where do I find a new pin pipe? I was going to turn one down. And thanks guys for the nomenclature!A new pin pipe is only $3.50

Dave

Any Kubota dealer can get you one.Where do I find a new pin pipe? I was going to turn one down. And thanks guys for the nomenclature!

Thanks again. Kubota dealers always worry me. They have some sensor that knows how much money you have plus 3 dollarsAny Kubota dealer can get you one.

They just seem pricey is all. $3.50 certainly is more than fair.Never had that issue with my dealer.

You're ahead of me. I just asked that question. The area I live in has minimal internet and everything goes through my phone. I'm missing messages due to the small screen. Your correct but I do have the means to make it flat. At this time both, the head and block are within 1/1000th of flat. I just asked if I need a spacer and how do I tell what thickness. I guess I'll need to know where I get one or more. Do they come in different thicknesses or do you stack them?When you say milling the block, you have this completely torn down for overhaul? I ask because the cast iron and silicon carbide dust I see on the pistons and in the pushrod bores from the sandpaper is concerning. Milling the deck may require a shim. NIW or lugbolt can offer more guidance on this.

You all are great.

I forgot to answer your question. No, I just have the head removed. I'm going to attempt to TIG the crack in the block. It appears to be located in a non vital area. This was a running engine but had oil in the coolant. You can see where the freezing raised the crack a couple of thousands. This is me buying other people's problems.... Final picture is the block prior to welding. If this all fails, I'll end up parting it out which I hate doing. Too neat of a little tractor.You're ahead of me. I just asked that question. The area I live in has minimal internet and everything goes through my phone. I'm missing messages due to the small screen and learning how to navigate the site. Your correct, but I do have the means to make it flat. I have a granite surface plate and straight edge. At this time both, the head and block are within 1/1000th of flat. I just asked if I need a spacer on I guess the same forum. How do I tell what thickness? I guess I'll need to know where I get one or more. Do they come in different thicknesses or do you stack them?

You all are great!

You're ahead of me. I just asked that question. The area I live in has minimal internet and everything goes through my phone. I'm missing messages due to the small screen and learning how to navigate the site. Your correct, but I do have the means to make it flat. I have a granite surface plate and straight edge. At this time both, the head and block are within 1/1000th of flat. I just asked if I need a spacer on I guess the same forum. How do I tell what thickness? I guess I'll need to know where I get one or more. Do they come in different thicknesses or do you stack them?You're ahead of me. I just asked that question. The area I live in has minimal internet and everything goes through my phone. I'm missing messages due to the small screen. Your correct but I do have the means to make it flat. At this time both, the head and block are within 1/1000th of flat. I just asked if I need a spacer and how do I tell what thickness. I guess I'll need to know where I get one or more. Do they come in different thicknesses or do you stack them?

You all are great.

You all are great!

[/QUOTE]

I forgot to answer your question. No, I just have the head removed. I'm going to attempt to TIG the crack in the block. It appears to be located in a non vital area. This was a running engine but had oil in the coolant. You can see where the freezing raised the crack a couple of thousands. This is me buying other people's problems.... Final 3 pictures are the block prior to welding. If this all fails, I'll end up parting it out which I hate doing. Too neat of a little tractor.

Attachments

-

574 KB Views: 110

-

572.3 KB Views: 99

-

563.4 KB Views: 105