MY 2000 B7500HST.

The top link has always been a really tight fit where it attaches to the tractor, to the point that you need to tap the link in if you remove itand want to put it back on. Today I was struggling with it when I wanted to move it from the top set of holes to the bottom set and got the wise idea to stick a prybar in the space between the two angled brackets and spread them out a whisker for clearance.

Bad idea.

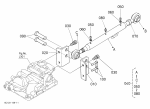

I ended up blowing one of the tapped holes in the casting apart. There doesn't seem to be any good robust way of patching in some additional bracketry and short of possibly brazing the broken part back on it doesn't look to be repairable. The one saving grace is that the hole is in the cover over the transaxle itself, the part that has the rock shaft and cylinder for the 3-point lift and not located in the main transaxle housing.

I did some looking around and you can still buy this part new... for $700 - $1,000. Ouch.

I managed to locate a used part for $225 so I will plan on going that route. The Stupid Tax is a real thing, I swear.

Makes me madder, knowing full well that I should have known better. Oh, well. Grousing about it isn't going to fix it.

Has anybody had this top cover off the transaxle and if so are there any gotchas I should be aware of? I do not have a repair manual but do have access to online exploded parts diagrams. I'm no pro mechanic but I have 30+ years of industrial Maintenance background and do virtually all of my own truck and auto repairs so I'm not too concerned about diving in. Hopefully the cab isn't going to get in the way too badly.

Thanks for any input!

The top link has always been a really tight fit where it attaches to the tractor, to the point that you need to tap the link in if you remove itand want to put it back on. Today I was struggling with it when I wanted to move it from the top set of holes to the bottom set and got the wise idea to stick a prybar in the space between the two angled brackets and spread them out a whisker for clearance.

Bad idea.

I ended up blowing one of the tapped holes in the casting apart. There doesn't seem to be any good robust way of patching in some additional bracketry and short of possibly brazing the broken part back on it doesn't look to be repairable. The one saving grace is that the hole is in the cover over the transaxle itself, the part that has the rock shaft and cylinder for the 3-point lift and not located in the main transaxle housing.

I did some looking around and you can still buy this part new... for $700 - $1,000. Ouch.

I managed to locate a used part for $225 so I will plan on going that route. The Stupid Tax is a real thing, I swear.

Makes me madder, knowing full well that I should have known better. Oh, well. Grousing about it isn't going to fix it.

Has anybody had this top cover off the transaxle and if so are there any gotchas I should be aware of? I do not have a repair manual but do have access to online exploded parts diagrams. I'm no pro mechanic but I have 30+ years of industrial Maintenance background and do virtually all of my own truck and auto repairs so I'm not too concerned about diving in. Hopefully the cab isn't going to get in the way too badly.

Thanks for any input!