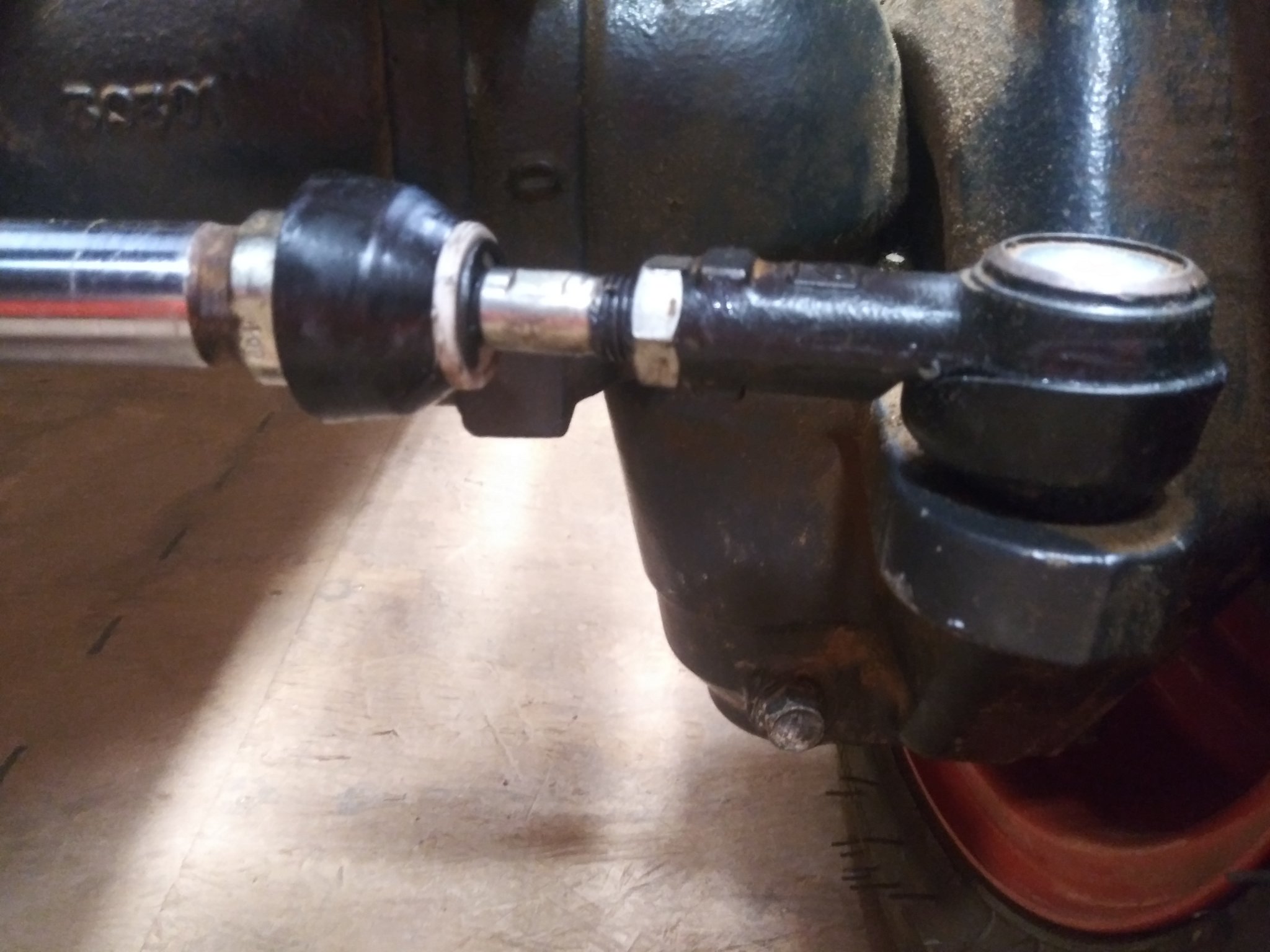

Tierod

- Thread starter phantomgeo

- Start date

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

You doing top and bottom boots? OR replacing just the tie rod?

Cheaper to do just the boots

Mark the threads or count how many are seen - take picture with cell phone

loosen nut -

jack up front end-

take pin out of castle nut-

loosen nut just enough so bolt is inside nut-

give the nut a firm smack up- or get a pickle fork - or tap the boss holding tie rod.

Remove nut -

pull out tie rod-

spin out the tie rod from steering.

Replace all boots or tie rod.

Cheaper to do just the boots

Mark the threads or count how many are seen - take picture with cell phone

loosen nut -

jack up front end-

take pin out of castle nut-

loosen nut just enough so bolt is inside nut-

give the nut a firm smack up- or get a pickle fork - or tap the boss holding tie rod.

Remove nut -

pull out tie rod-

spin out the tie rod from steering.

Replace all boots or tie rod.

Hokie ... while your expertise is certainly evident... you may be overlooking the fact the replacement tie rod may not be identical to the original. An aftermarket item might (and very likely may) have different dimensions than that removed.

A more accurate method would be to measure the distance between tie-end centers and see that the new installation is the exact same (OR to completely Re-do the toe-in/toe-out adjustments per the manual specs.)

Phantomgeo, there’s no reason to change a tie rod end simply because of a torn boot. The boot’s purpose is to prevent contamination from dirt/mud/etc from getting inside the mechanism and you can take an old inner-tube, cut a rectangle from it, wrap it around the existing tie-rod-end twice (leaving the over-lapped seam on the bottom) and secure it on each end of the innertube with ty-wraps or hose clamps or baleing wire. It will accomplish the objective and cost virtually nothing.

Do not try to hammer the existing tie-rod-end off the pitman-arm... (unless you know how to do this without stressing the arm, such as by bracing the arm with a larger mallet and striking the old tie rod on the end of it’s stud. If you don’t understand that comment.... buy a cheap fork or borrow one from AutoZone. If you get your tie rod ends from somewhere else, buy any tie rod end from them and return it ... the clerk won’t care.... give them some business in other ways if your conscience bothers you.)

HOpe this helps.

A more accurate method would be to measure the distance between tie-end centers and see that the new installation is the exact same (OR to completely Re-do the toe-in/toe-out adjustments per the manual specs.)

Phantomgeo, there’s no reason to change a tie rod end simply because of a torn boot. The boot’s purpose is to prevent contamination from dirt/mud/etc from getting inside the mechanism and you can take an old inner-tube, cut a rectangle from it, wrap it around the existing tie-rod-end twice (leaving the over-lapped seam on the bottom) and secure it on each end of the innertube with ty-wraps or hose clamps or baleing wire. It will accomplish the objective and cost virtually nothing.

Do not try to hammer the existing tie-rod-end off the pitman-arm... (unless you know how to do this without stressing the arm, such as by bracing the arm with a larger mallet and striking the old tie rod on the end of it’s stud. If you don’t understand that comment.... buy a cheap fork or borrow one from AutoZone. If you get your tie rod ends from somewhere else, buy any tie rod end from them and return it ... the clerk won’t care.... give them some business in other ways if your conscience bothers you.)

HOpe this helps.

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

Hokie ... while your expertise is certainly evident... you may be overlooking the fact the replacement tie rod may not be identical to the original. An aftermarket item might (and very likely may) have different dimensions than that removed.

A more accurate method would be to measure the distance between tie-end centers and see that the new installation is the exact same (OR to completely Re-do the toe-in/toe-out adjustments per the manual specs.)

Phantomgeo, there’s no reason to change a tie rod end simply because of a torn boot. The boot’s purpose is to prevent contamination from dirt/mud/etc from getting inside the mechanism and you can take an old inner-tube, cut a rectangle from it, wrap it around the existing tie-rod-end twice (leaving the over-lapped seam on the bottom) and secure it on each end of the innertube with ty-wraps or hose clamps or baleing wire. It will accomplish the objective and cost virtually nothing.

Do not try to hammer the existing tie-rod-end off the pitman-arm... (unless you know how to do this without stressing the arm, such as by bracing the arm with a larger mallet and striking the old tie rod on the end of it’s stud. If you don’t understand that comment.... buy a cheap fork or borrow one from AutoZone. If you get your tie rod ends from somewhere else, buy any tie rod end from them and return it ... the clerk won’t care.... give them some business in other ways if your conscience bothers you.)

HOpe this helps.

Geo - I did think of that as I was typing(but the tie rod is the female part-thus the steering linkage will still have the same # of threads.... unless the end is completely different

..... but like you, I am hoping he is replacing just the boot!

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

true true!!! When I replaced the boots...... I packed as much grease in em that I possibly could!!!!‘Tis a pity they aren’t greaseable...

The aftermarket ones are.... Not the OEM ones. ....and, to remove the tie rod end from the knuckle casting, just wack the casting where the end fits through it with a hammer and it will pop right out.‘Tis a pity they aren’t greaseable...

Don't even think about replacing the radial joint at the end of the steering ram, super expensive, aftermarket or OEM.