It's functioning quite nicely as a ROPS in that position. If what you say is true, why isn't it in the Op Manual? Not even mentioned in the Op Manual.The 45 degree position is not meant to be used, the hole for the pin is too large and the strength of the ROPS is greatly reduced. You can use that hole to keep the folded ROPS in place when trailering.

Stop the ROPS bar from loud squeaking when underway.

- Thread starter Orange man hero

- Start date

The diagrams in your manual show the pin in the center hole with the ROPS down, and in the proper hole with the ROPS raised. The strength and protection of the ROPS will be greatly reduced in the middle position. If you still don't agree, run it by an engineer so he/she can give you the numbers.It's functioning quite nicely as a ROPS in that position. If what you say is true, why isn't it in the Op Manual? Not even mentioned in the Op Manual.

Bingo.Get yourself two bolts (i'll look for the size) and tighten them down. Alternatively, you can buy the knobs that come on some BX series from your dealer. They thread into the front of the ROPS at the joint. You'll see a welded nut on the front side.

I can't remember which thread I sued but it was one of these two sizes....

ROPS Jamb bolts Thread size metric M10x1.5mm, M10x1.25

You can see them installed here (two shiny bolts).

View attachment 75585

I did much the same with my B3350.

Problem solved.

SDT

I agree, and I am an engineer, retired.The diagrams in your manual show the pin in the center hole with the ROPS down, and in the proper hole with the ROPS raised. The strength and protection of the ROPS will be greatly reduced in the middle position. If you still don't agree, run it by an engineer so he/she can give you the numbers.

SDT

leveraddict

Well-known member

Equipment

2017 BX23S 60" LP BoxBlade 54" mower 60" BackBlade EA 12" 1 bottom plow & Forks

The BX's came with two knobs for the rops. Once the knob is set theres no struggle to line the rops holes up for the pins. Kubota should put them on all the tractors.

I am, too. It works quite well at the 45 degree position. Pin is as tight as it is in the other 2 positions. Not shown in Op Manual.I agree, and I am an engineer, retired.

SDT

"I am, too. It works quite well at the 45 degree position. Pin is as tight as it is in the other 2 positions. Not shown in Op Manual. "

When you rolled over the tractor to test it, were you able to keep your head off the ground?

When you rolled over the tractor to test it, were you able to keep your head off the ground?

Nothing is said about the mid position at all. No warning about conflict with top link when dropped either."I am, too. It works quite well at the 45 degree position. Pin is as tight as it is in the other 2 positions. Not shown in Op Manual. "

When you rolled over the tractor to test it, were you able to keep your head off the ground?

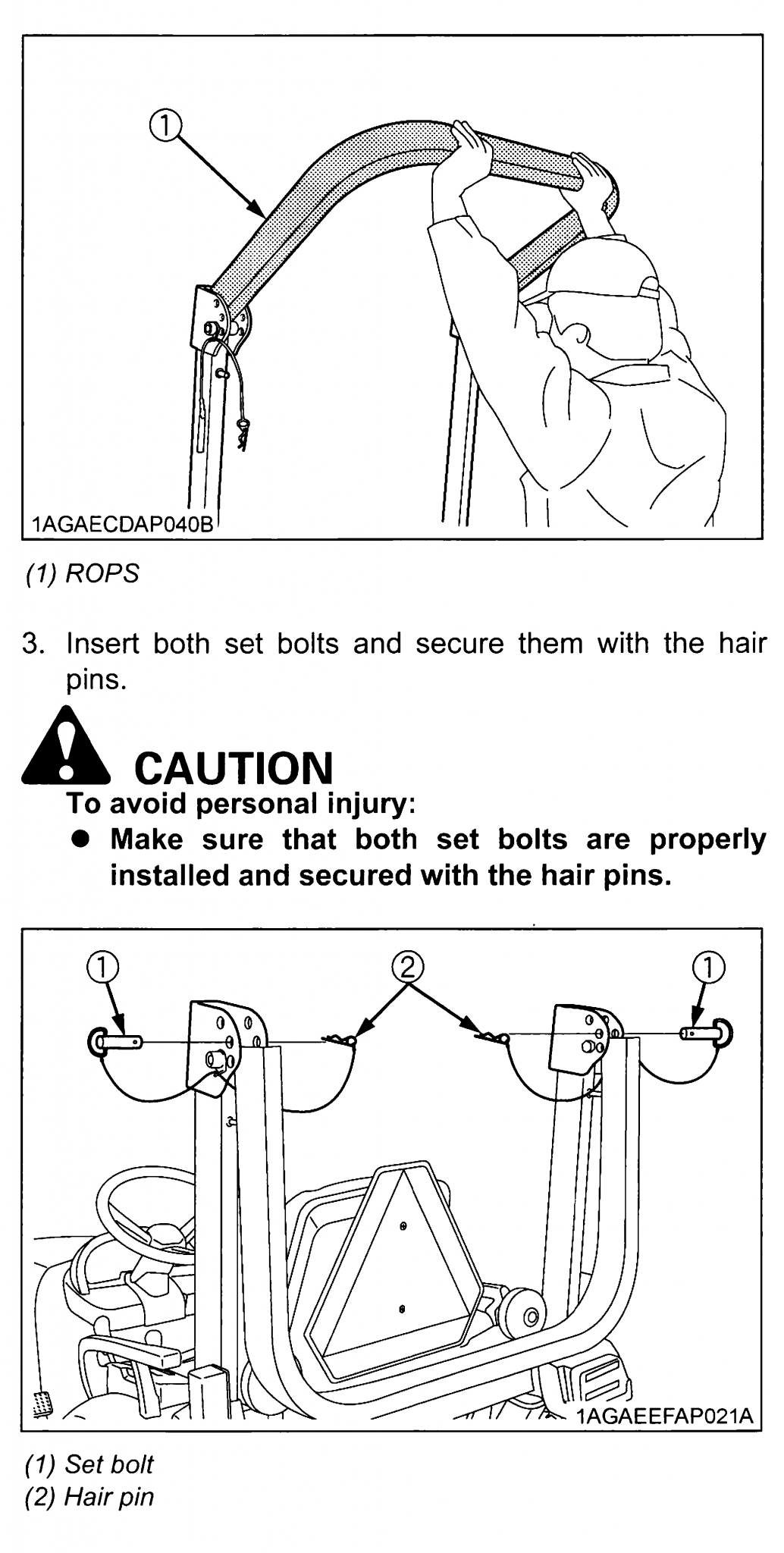

View attachment 75850

View attachment 75849

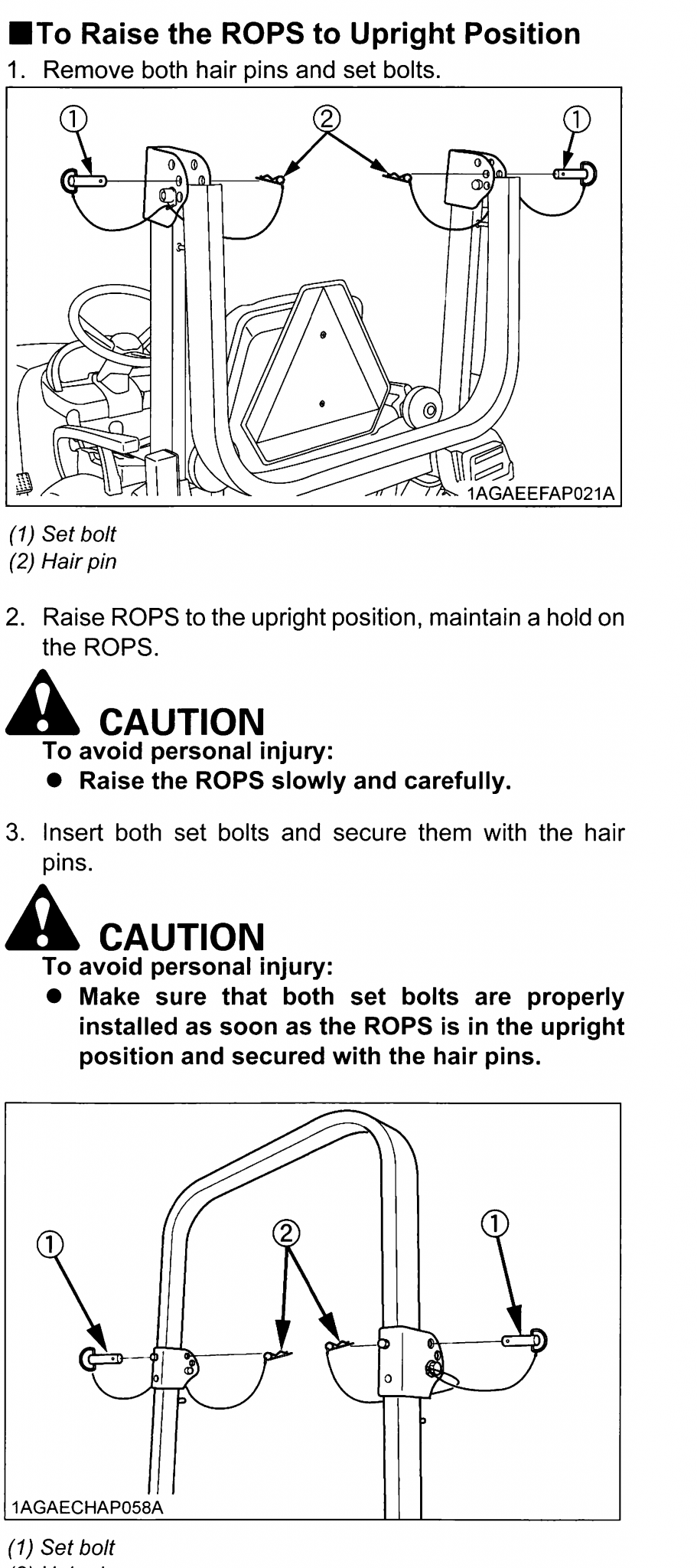

There are two drawings showing the proper use of the center hole, one of them is posted above.Nothing is said about the mid position at all. No warning about conflict with top link when dropped either.

There is this line you missed:

• Before proceeding to fold ROPS, check for any

possible interference with installed

implements and attachments.

If interference occurs, contact your KUBOTA

Dealer

Not clear as to what is shown. Are the middle holes to lock the bar in the fully down position?There are two drawings showing the proper use of the center hole, one of them is posted above.

There is this line you missed:

• Before proceeding to fold ROPS, check for any

possible interference with installed

implements and attachments.

If interference occurs, contact your KUBOTA

Dealer

It's working great with the top bar at 45 degrees. At a height to fully protect my head and low enough to clear doorways. It's great.

bmblank

Well-known member

Equipment

2020 L3901HST, LA525 Loader, 66" Q/A Bucket, PFL2042 Forks, Meteor SB68PT Blower

You need to remember that the ROPS needs to be at a certain level higher than your head. Draw a straight line from the top of the ROPS to the front of your tractor - not a level line at the top of the ROPS. That's where it'll be sitting when it's upside down.

Realistically, the ROPS being up should prevent it from rolling completely over. With any luck it'll only roll on its side. With shorter ROPS it's a lot more likely to roll all the way over.

Realistically, the ROPS being up should prevent it from rolling completely over. With any luck it'll only roll on its side. With shorter ROPS it's a lot more likely to roll all the way over.

I use a small piece of rubber glued on the lower part of rops, so that when you put the upper section up it pinches the rubber just enough to get the pins in. No rattle and no extra bolts to deal with.

I did the same thing but with foam backed tape. Just enough give to get the pins in and out but no rattle.I use a small piece of rubber glued on the lower part of rops, so that when you put the upper section up it pinches the rubber just enough to get the pins in. No rattle and no extra bolts to deal with.

If you're working for the government (sounds like it), allow them to raise the protection bar between the hood and the FEL. This would allow for a lower rear ROPS.You need to remember that the ROPS needs to be at a certain level higher than your head. Draw a straight line from the top of the ROPS to the front of your tractor - not a level line at the top of the ROPS. That's where it'll be sitting when it's upside down.

Realistically, the ROPS being up should prevent it from rolling completely over. With any luck it'll only roll on its side. With shorter ROPS it's a lot more likely to roll all the way over.

The net affect of putting the ROPS top half at an angle would be to effectively lower the height. IF this was a recommended solution, why would Kubota not just lower the height of the ROPS to begin with?If you're working for the government (sounds like it), allow them to raise the protection bar between the hood and the FEL. This would allow for a lower rear ROPS.

Probably because a lower ROPS height offers less overall protection. And certainly, with the top angled during a roll over, the lever arm at the joint will be much greater than if the ROPS top half were vertical.

I would contact Kubota and ask if they recommend the ROPS being used with the top half at a 45 degree angle. NO actually I would not bother, because I already know the answer...