Have a BX25D with a Countryline post hole digger. Working in some tough ground and more than once the auger corkscrews in and stalls the tractor before I have a chance to disengage. I try and disengage to PTO before it stalls. But more than once the auger corkscrews in, tractor stalls and I can't lift the arm. Walking tractor back and forth a couple of time gets the auger unstuck. I try to be careful, but it happens. Am I doing any damage to my tractor?

Stalling tractor when using posthole digger

- Thread starter stevewhitts

- Start date

armylifer

Well-known member

Lifetime Member

Equipment

BX1860, FEL, RCK54P MMM, BB1548 Box Scraper, Quick Hitch, Piranha Bar, BX6315

It is more likely that you are bending something on the auger. You may want to finesse the auger by lifting out of the hole before the auger pulls into the dirt and you stall out. Using an auger in hard pack dirt or rocky soil is an art form. If you do not pull the auger out of the hole frequently, you get stuck, as you now know.

Minor detail: the little BX has no clutch pedal, so its either shut off the PTO or raise the auger out of the hole quickly when it bogs.Always have your foot on the clutch, Once it starts to cork screw into the earth, step on the Clutch.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Not the best model of tractor or Post hole digger to be working with in a hard situation.

You asked if you doing any damage, you very well could be doing damage.

I would avoid doing it very often, you can do all sorts of damage.

You asked if you doing any damage, you very well could be doing damage.

I would avoid doing it very often, you can do all sorts of damage.

Runs With Scissors

Well-known member

Equipment

L2501 TLB , Grappel, Brush Hog, Box Blade, Ballast box, Forks, Tiller, PH digger

I agree.Take smaller "bites" into the ground. More up and down... Always have your foot on the clutch, Once it starts to cork screw into the earth, step on the Clutch. Good to have a 2 or 3 foot pipe wrench to unscrew the auger instead of rocking back and forth.

Sounds like “pecking” at it, is the best method in that type of soil. Around here, there are pockets of clay, and man if you get that auger stuck, your'e F'd. ……BTDT.

A “cheater bar” is a good idea too.

If your soil does this to you a LOT….. remove one (or both) of the ”teeth” from the leading edge of the screw to reduce its aggressiveness .

(This is not something I’ve done deliberately…. but I lost a tooth off one side and noticed the improvement in clay.)

(This is not something I’ve done deliberately…. but I lost a tooth off one side and noticed the improvement in clay.)

ChiefWebb

Member

Equipment

MX5100, ZD331, Z242KW-48 & RTV900, Woods Stump Grinder, Armstrong Ag Grappler

I too have clay and when its hard and dry I use the smallest diameter auger my brand makes to drill my hole then I switch to the larger auger and ream the hole out larger.

ChiefWebb

Member

Equipment

MX5100, ZD331, Z242KW-48 & RTV900, Woods Stump Grinder, Armstrong Ag Grappler

The larger auger seems to just to center it's self in the smaller hole and follows on down. Always centers up, never had an issue with it wanting to wonder off center. Similar to enlarging a hole when drilling material with a twist drill bit.

Steve

Sounds as if you need to turn rate of drop screw in a some so 3pt is slower to lower. Also if not already doing so lower engine rpm's to about 1200 rpms & raise/lower auger more frequently while attempting to dig a hole.

Sounds as if you need to turn rate of drop screw in a some so 3pt is slower to lower. Also if not already doing so lower engine rpm's to about 1200 rpms & raise/lower auger more frequently while attempting to dig a hole.

Probably worth mentioning for those getting started with a PHD: Posthole diggers can be one of the more hazardous 3 point attachments to work with. Don't take chances around that spinning auger and the PTO shaft. Difficult soil conditions only add to the hazards.

armylifer

Well-known member

Lifetime Member

Equipment

BX1860, FEL, RCK54P MMM, BB1548 Box Scraper, Quick Hitch, Piranha Bar, BX6315

For his particular tractor 1200 RPM is idle speed. He needs to operate at 1600 to 1800 for that auger to work in clay properly. I have dug many holes in my rocky soil at 1800 RPM. His D902 engine is rated at 3200 RPM for max power. He probably should start at 1800 RPM and adjust for his particular needs from there.Steve

Sounds as if you need to turn rate of drop screw in a some so 3pt is slower to lower. Also if not already doing so lower engine rpm's to about 1200 rpms & raise/lower auger more frequently while attempting to dig a hole.

I'm not disagreeing that smaller engine requires more rpm to operate a post hole digger than a higher CID?Liter engine. 23 hp engine requiring 1600 engine rpm 's to dig a hole with a pto driven post hole digger even in clay soil sounds high to me.

Long story/short story the lower the engine/pto speed is makes controlling posthole digger auger digging depth/load so much easier.

Long story/short story the lower the engine/pto speed is makes controlling posthole digger auger digging depth/load so much easier.

armylifer

Well-known member

Lifetime Member

Equipment

BX1860, FEL, RCK54P MMM, BB1548 Box Scraper, Quick Hitch, Piranha Bar, BX6315

What you are not realizing is that the hydraulic fluid is not flowing enough to even spin the auger at engine RPM 1200. The D902 engine is idling at 1200 rpm. The auger spins VERY slowly at 1600 RPM in the OP's tractor. You obviously don't believe me when I say that 1600 to 1800 RPM with the BX25 is appropriate for digging in hard pack but I speak from experience, not theory.I'm not disagreeing that smaller engine requires more rpm to operate a post hole digger than a higher CID?Liter engine. 23 hp engine requiring 1600 engine rpm 's to dig a hole with a pto driven post hole digger even in clay soil sounds high to me.

Long story/short story the lower the engine/pto speed is makes controlling posthole digger auger digging depth/load so much easier.

I fail to see where stevewhitts stated his Countryline post hole digger was hydraulically powered not pto driven!

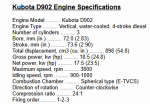

Idle speed for that engine that I located stated 900-1000 not 1200 rpms. See photo below

I have no personal experience with that model 23 hp tractor. I own a Zero-turn lawnmower with more HP. So if 1600 engine rpm's is the lowest rpm that one can operate pto then I understand.

I was employed by a tractor dealer for 21 yrs delivering/demonstrating many tractors & served last 13 yrs of that employment as the service manager. After leaving dealership I've been custom farming since for 35 yrs therefore I've operated several pto powered implements.

Idle speed for that engine that I located stated 900-1000 not 1200 rpms. See photo below

I have no personal experience with that model 23 hp tractor. I own a Zero-turn lawnmower with more HP. So if 1600 engine rpm's is the lowest rpm that one can operate pto then I understand.

I was employed by a tractor dealer for 21 yrs delivering/demonstrating many tractors & served last 13 yrs of that employment as the service manager. After leaving dealership I've been custom farming since for 35 yrs therefore I've operated several pto powered implements.

Attachments

-

18.7 KB Views: 58

Last edited:

I rented a one-man PHD back in 2016 when I built a deck for the hot tub, and I have a SSQA Land Pride HD25 with three augers including a rock auger, but have zero experience with a 3-point PHD. The reason is that I would never have bought a 3-point PHD for a number of reasons. To me they're less than ideal and need near perfect conditions to be of any use.

I would say that if the ground is hard, and nothing is harder than rock, a rock auger is the way to go. I've tried punching holes in the ground here using a 9" auger and it's a joke. The 6" rock auger does an amazing job but you have to go slow. A PHD that uses an hydraulic pump and that is mounted to the FEL is so much nicer to use with far more control with the ability to reverse rotation and adjust auger angle with ease. I would also add that a gear drive tractor trumps an HST when running a SSQA mounted PHD.

The takeaway here is that the choice of auger can make a big difference, and if members here are considering a PHD, look closely at SSQA hydraulically powered augers that can run off the 3rd function. When sized appropriately they're extremely effective.

I would say that if the ground is hard, and nothing is harder than rock, a rock auger is the way to go. I've tried punching holes in the ground here using a 9" auger and it's a joke. The 6" rock auger does an amazing job but you have to go slow. A PHD that uses an hydraulic pump and that is mounted to the FEL is so much nicer to use with far more control with the ability to reverse rotation and adjust auger angle with ease. I would also add that a gear drive tractor trumps an HST when running a SSQA mounted PHD.

The takeaway here is that the choice of auger can make a big difference, and if members here are considering a PHD, look closely at SSQA hydraulically powered augers that can run off the 3rd function. When sized appropriately they're extremely effective.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

Just to be clear, I mean a PHD that runs off an hydraulic pump that runs off an hydraulic pump on the tractor as opposed to a 3-point PTO driven PHD. For starters, an HST tractor will generate a lot more heat in the transmission oil compared to a gear drive tractor and subject that oil to more stress. The MX6000 supposedly has a pump capacity of 9.5 gpm compared to 11.0 gpm for the M6060, but it would be interesting to measure the actual flow rate of the 3rd function circuits in both. I'm betting they're a lot further apart than 1.5 gpm due to how and where the transmission oil is being used when the tractor is running.@McMXi

You stated “I would also add that a gear drive tractor trumps an HST when running a SSQA mounted PHD.”

Would you expound on why you say gear is better than HST in usage of a PHD?

armylifer

Well-known member

Lifetime Member

Equipment

BX1860, FEL, RCK54P MMM, BB1548 Box Scraper, Quick Hitch, Piranha Bar, BX6315

I think that you got the specifications for the D902 engine for use in a generator. Here is the specifications for that engine in a BX23S which is the same for the BX25D.I fail to see where stevewhitts stated his Countryline post hole digger was hydraulically powered not pto driven!

Idle speed for that engine that I located stated 900-1000 not 1200 rpms. See photo below

I have no personal experience with that model 23 hp tractor. I own a Zero-turn lawnmower with more HP. So if 1600 engine rpm's is the lowest rpm that one can operate pto then I understand.

I was employed by a tractor dealer for 21 yrs delivering/demonstrating many tractors & served last 13 yrs of that employment as the service manager. After leaving dealership I've been custom farming since for 35 yrs therefore I've operated several pto powered implements.

The specs that you attached are for a generator. The specs for the D902 in the BX tractor are:I fail to see where stevewhitts stated his Countryline post hole digger was hydraulically powered not pto driven!

Idle speed for that engine that I located stated 900-1000 not 1200 rpms. See photo below

I have no personal experience with that model 23 hp tractor. I own a Zero-turn lawnmower with more HP. So if 1600 engine rpm's is the lowest rpm that one can operate pto then I understand.

I was employed by a tractor dealer for 21 yrs delivering/demonstrating many tractors & served last 13 yrs of that employment as the service manager. After leaving dealership I've been custom farming since for 35 yrs therefore I've operated several pto powered implements.

Rated revolution rpm 3200

Low idling revolution rpm 1350 to 1550

As for the PHD being a PTO driven, I made a wrong assumption about the kind of PHD he was using, but 1200 RPM is still too slow regardless.