These older K's need a little Italian tune-up occasionally from what I've been told and experienced myself. My B7100 was a real bear to start until I replaced the glow plug indicator (resistor) and put some time on it. It had been sitting a long time prior to me getting it. Now, it just needs a tickle of plug and it pops right off.Thanks,

It appears that this question has been asked before and they had to take the whole unit off and flush it.

Except for one guy who said it just taps right out.

Yesterday I was operating the tractor moving some water buckets to water my trees and it briefly started knocking with some dark smoke out the exhaust. Probably for about 10-15 seconds.

Then it cleared up and ran great again. I'm guessing the Seafoam knocked something loose but it was a bit unnerving until it cleared up.

I was about to shut it down but then it went away and went back to normal.

Later in the day I rototilled a section of ground that needed smoothing out and reseeding and it performed fantastic at full throttle for 30 minutes.

New here with a B6000

- Thread starter trevoroni

- Start date

Thanks for the comment.These older K's need a little Italian tune-up occasionally from what I've been told and experienced myself. My B7100 was a real bear to start until I replaced the glow plug indicator (resistor) and put some time on it. It had been sitting a long time prior to me getting it. Now, it just needs a tickle of plug and it pops right off.

I think that's the case as well.

Same as most equipment it's better to use them regularly then having them sit. This one had only been used once in the spring to rototill the previous owners garden for the past 4 years. Before that who knows what it was used for in its previous life.

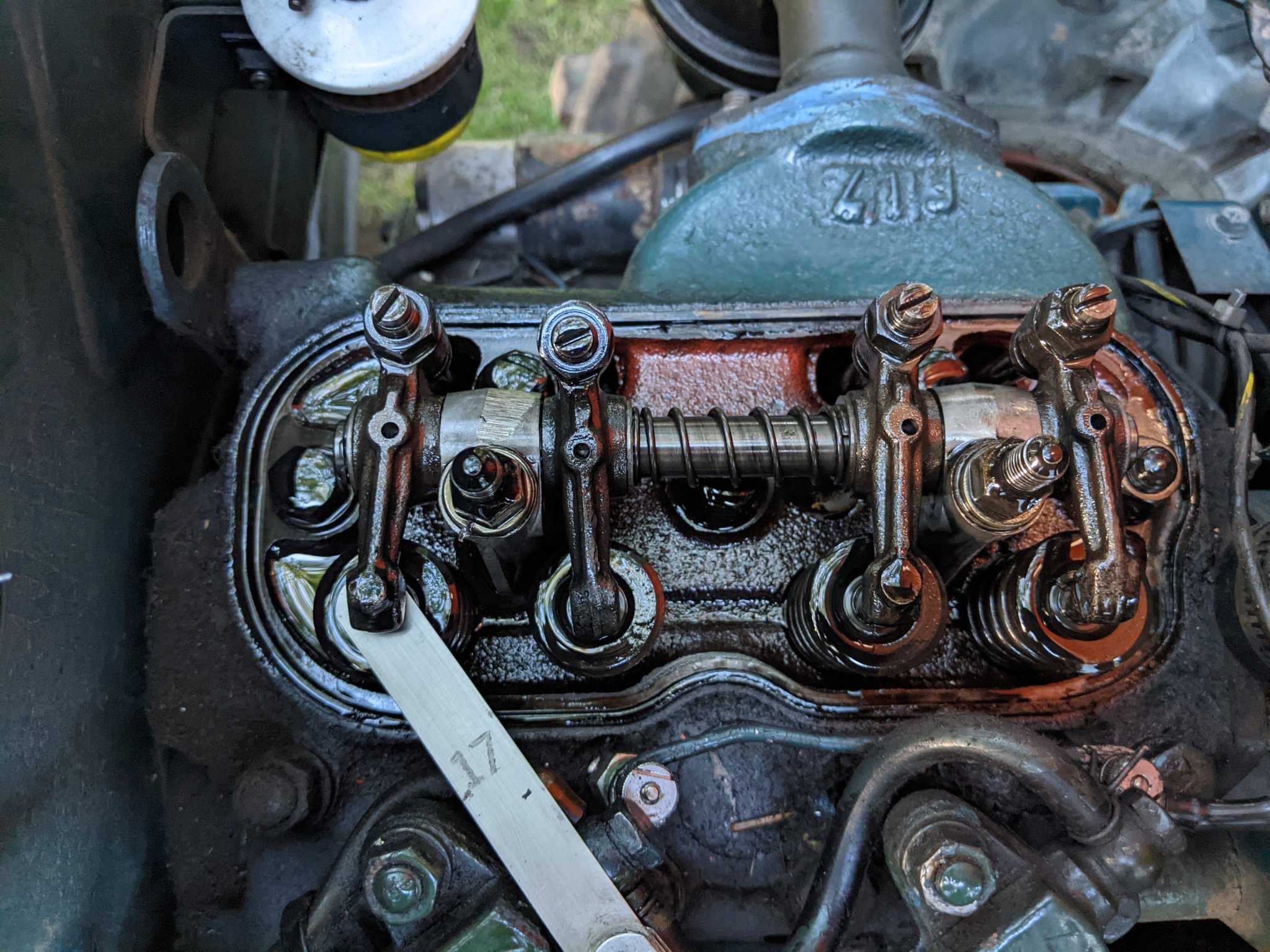

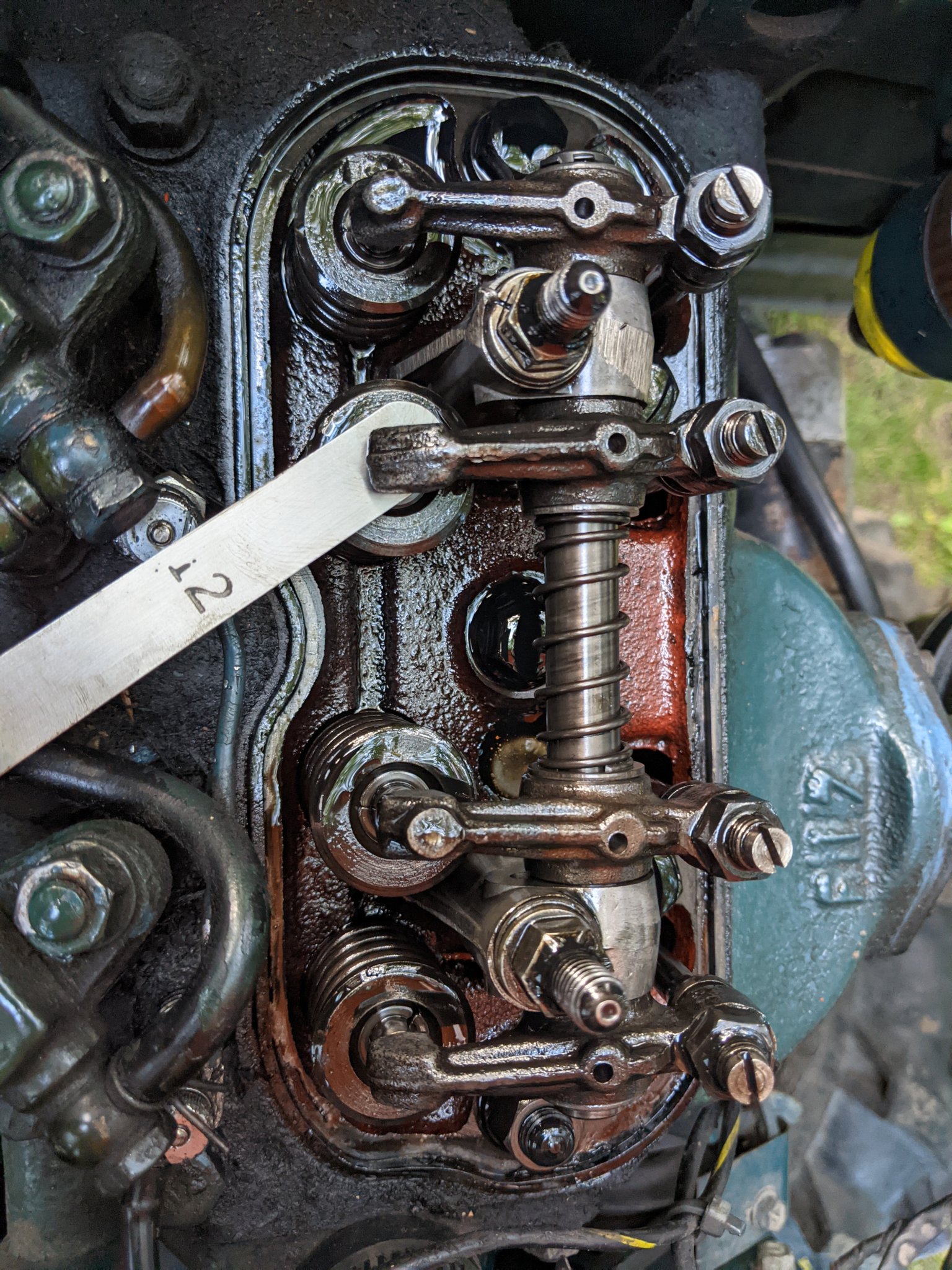

I adjusted the valves tonight.

They were all between 12-17 thou. Spec is 8-10. I adjusted them all to 9.

I think that was the easiest valve adjustment I've ever done.

Also replaced the fuel hose and clamps going over the valve cover since I had to remove it anyways.

Is there a procedure for adjusting the compression release? I didn't see anything for it in either the operators or service manual. It doesn't seem like it's doing anything now, and the screws are adjusted pretty much flush to the cover on the inside.

They were all between 12-17 thou. Spec is 8-10. I adjusted them all to 9.

I think that was the easiest valve adjustment I've ever done.

Also replaced the fuel hose and clamps going over the valve cover since I had to remove it anyways.

Is there a procedure for adjusting the compression release? I didn't see anything for it in either the operators or service manual. It doesn't seem like it's doing anything now, and the screws are adjusted pretty much flush to the cover on the inside.

Next up, injector removal and taking in for cleaning/testing.

And then if the hard starting is still present a compression test and possibly a head gasket replacement.... It did kind of feel like cylinder 1, closest to the operator was harder to turn over the compression stroke than cylinder 2, the one closest to the rad, but not by much, could have been the awkward angle trying to watch the valves and turn the ratchet while reaching around the hood.

After the valve adjustment it seemed less clacky, especially after it warmed up.

But it could have been the equivalent of butt dyno ears...

And then if the hard starting is still present a compression test and possibly a head gasket replacement.... It did kind of feel like cylinder 1, closest to the operator was harder to turn over the compression stroke than cylinder 2, the one closest to the rad, but not by much, could have been the awkward angle trying to watch the valves and turn the ratchet while reaching around the hood.

After the valve adjustment it seemed less clacky, especially after it warmed up.

But it could have been the equivalent of butt dyno ears...

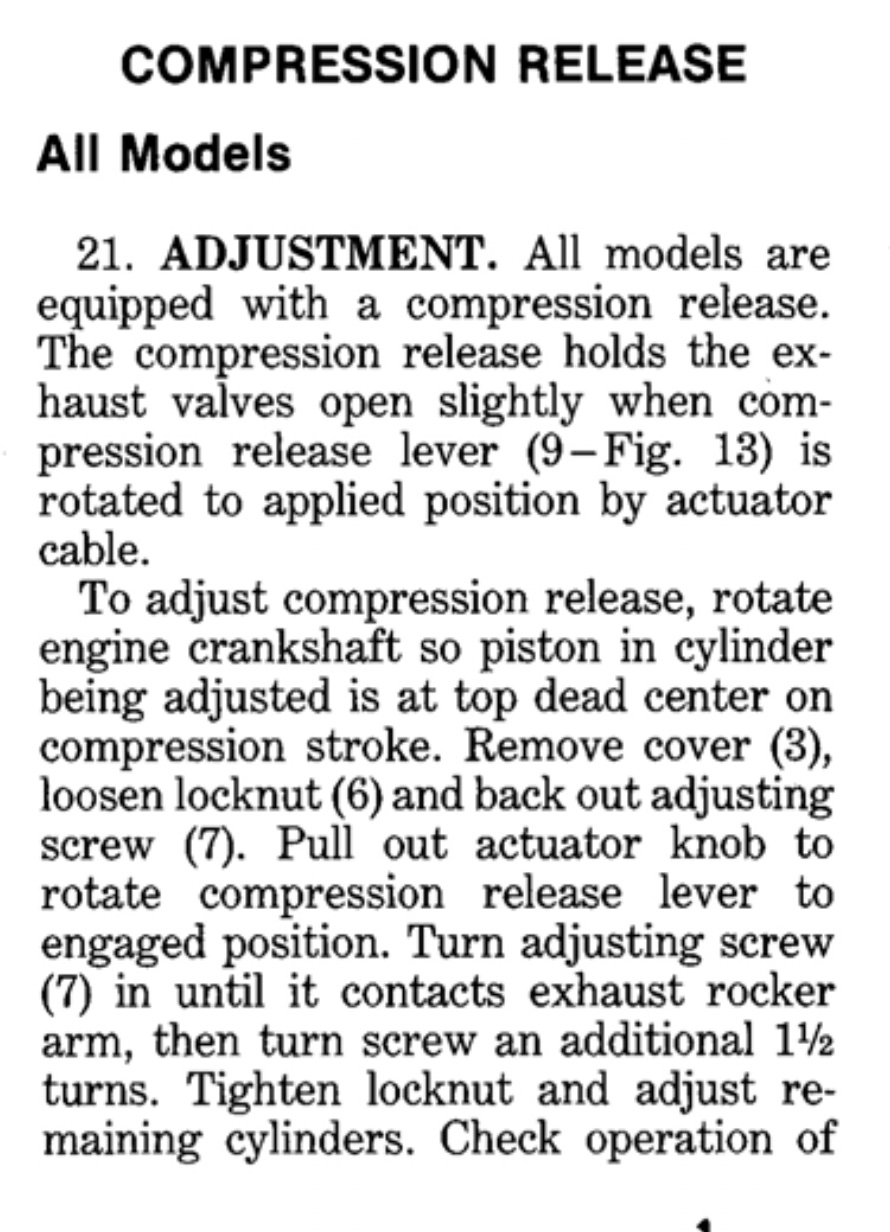

I adjusted the compression relief tonight.

It definitely wasn't doing anything before.

After adjusting, if anything I made it a little too tight, there's about an inch of free play before it starts opening the valves. Before I could pull it all the way out... Like 4" and nothing would happen.

It took a little bit of figuring out since when I loosened the locknuts the first time the arms came off the flats of the cam.

I ended up taking the whole valve cover off again and making sure that everything was functioning properly, luckily I made the new fuel line about 1/2" longer yesterday so I could squeak it out without having to bleed the line again.

Then removed the linkage between the 2 arms and adjusting them separately.

I forgot to take a picture of the timing marks on the fly wheel yesterday, I was worried they would have been marked in Japanese characters being a grey market tractor but they were marked normal.

I followed the instructions for a B5100, B6100, B7100 that Lil foot posted when someone else asked the same question.

It definitely wasn't doing anything before.

After adjusting, if anything I made it a little too tight, there's about an inch of free play before it starts opening the valves. Before I could pull it all the way out... Like 4" and nothing would happen.

It took a little bit of figuring out since when I loosened the locknuts the first time the arms came off the flats of the cam.

I ended up taking the whole valve cover off again and making sure that everything was functioning properly, luckily I made the new fuel line about 1/2" longer yesterday so I could squeak it out without having to bleed the line again.

Then removed the linkage between the 2 arms and adjusting them separately.

I forgot to take a picture of the timing marks on the fly wheel yesterday, I was worried they would have been marked in Japanese characters being a grey market tractor but they were marked normal.

I followed the instructions for a B5100, B6100, B7100 that Lil foot posted when someone else asked the same question.

From my B5100/6100/7100 service manual:

(for what it is worth)

Last edited:

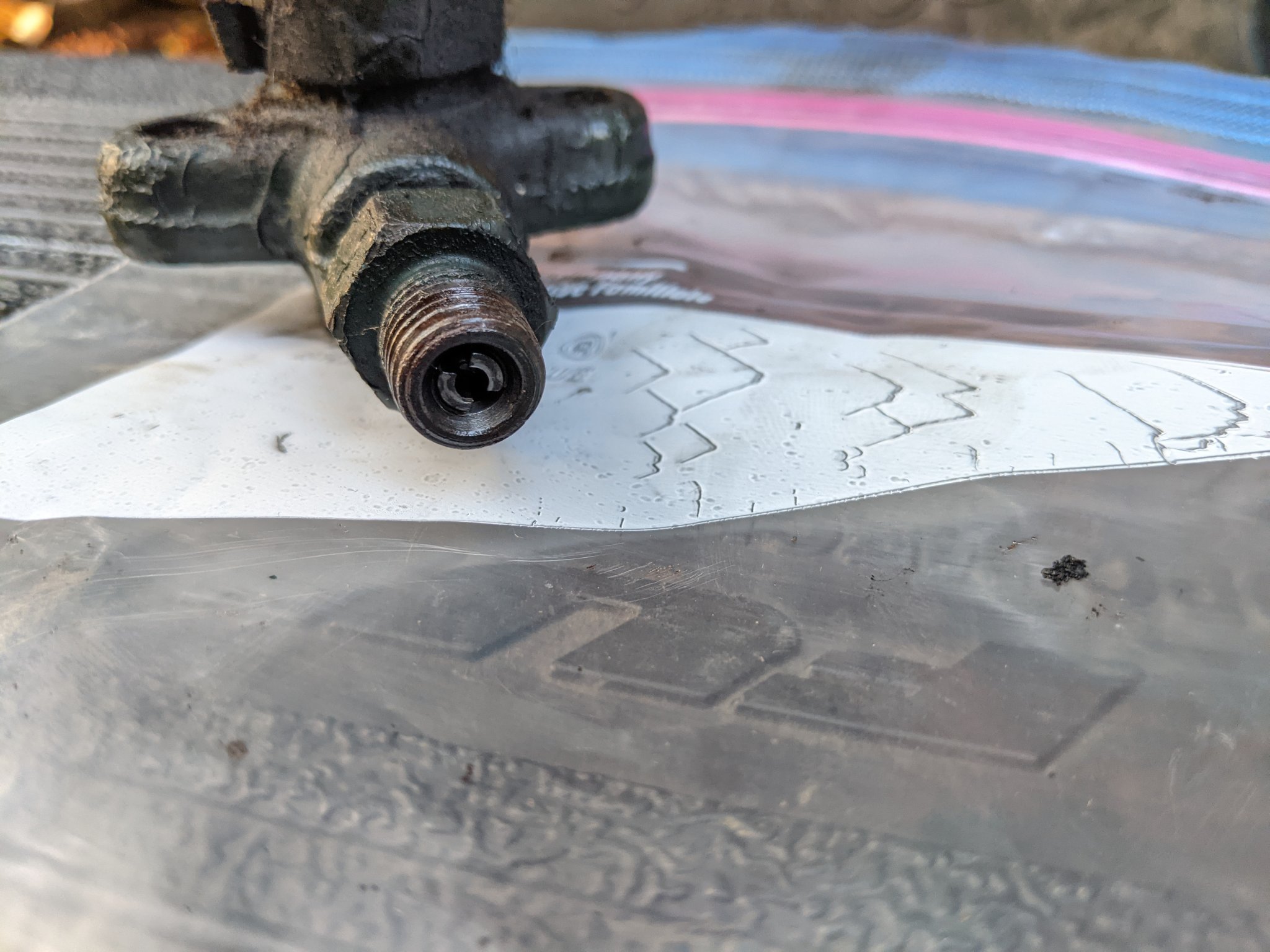

I pulled the injector closest to the operator tonight... It came out no problem. Both the return lines to the tank decintegrated when I pulled them off.

Externally it looks like it needs a good cleaning so I imagine the insides look the same.

The radiator side didn't come out so easy so I tapped it a bit and put some pb blaster around it. After the bit of tapping it started to rotate a bit but I didn't want to risk breaking it since they're NLA so I decided to let it soak for the night.

Hopefully it comes free tomorrow because Tuesday I'm leaving work early to take the girls to the dentist in town which is a couple of blocks away from the diesel injection shop.

Externally it looks like it needs a good cleaning so I imagine the insides look the same.

The radiator side didn't come out so easy so I tapped it a bit and put some pb blaster around it. After the bit of tapping it started to rotate a bit but I didn't want to risk breaking it since they're NLA so I decided to let it soak for the night.

Hopefully it comes free tomorrow because Tuesday I'm leaving work early to take the girls to the dentist in town which is a couple of blocks away from the diesel injection shop.

I got the other injector out this morning.

The PB Blaster helped a bit but I remembered reading somewhere that you can crank it over to use the compression of the cylinder to pop it loose. It took a bit more tapping back and forth and a few rotations of the crank by hand for it to pop loose.

It looks like this one may have been leaking a bit.

The PB Blaster helped a bit but I remembered reading somewhere that you can crank it over to use the compression of the cylinder to pop it loose. It took a bit more tapping back and forth and a few rotations of the crank by hand for it to pop loose.

It looks like this one may have been leaking a bit.

Dropped the injectors off at the shop this afternoon.

We will see what kind of shape they are in and what they can do to fix them up.

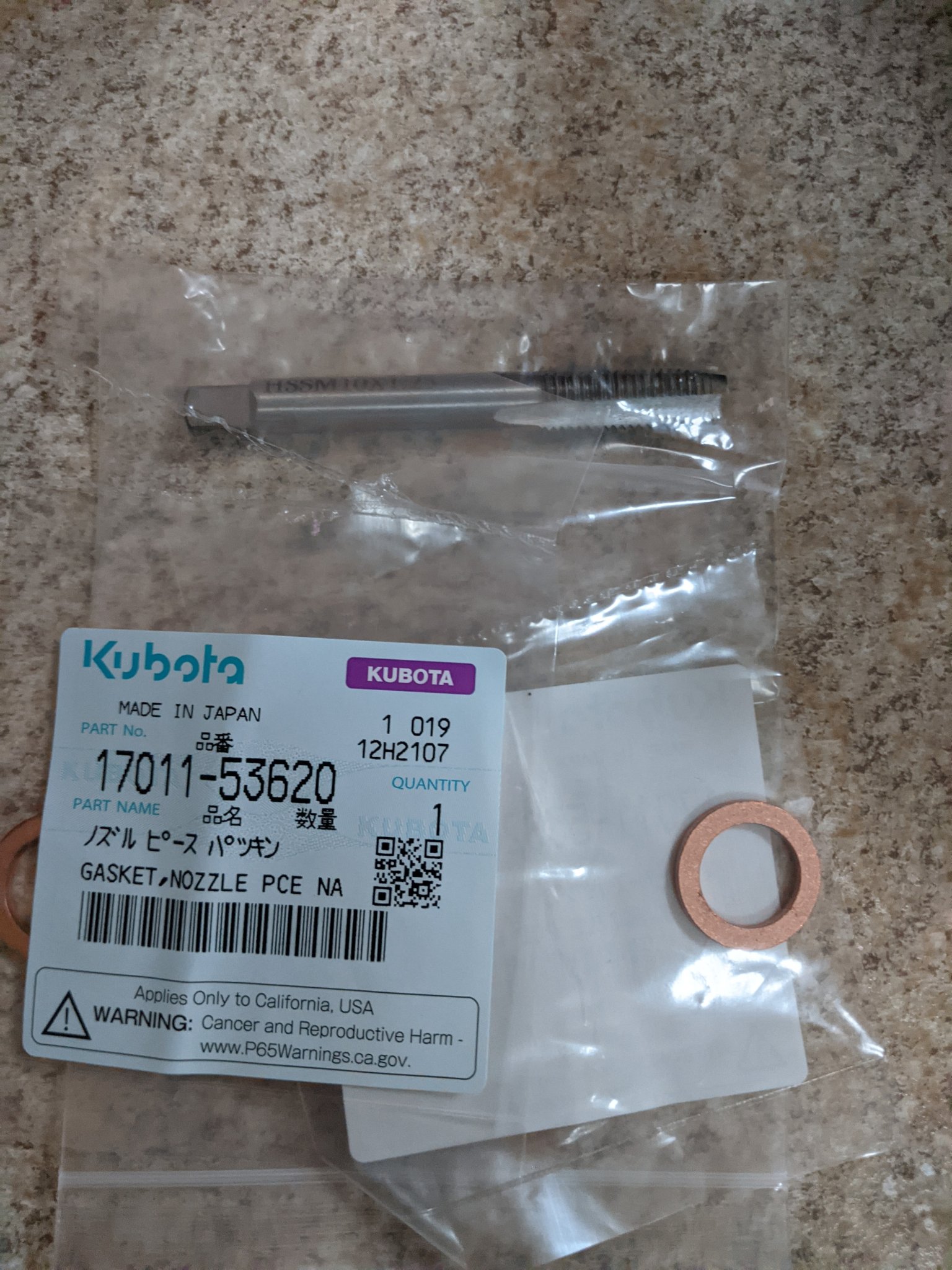

Also ordered an M10x1.25 tap to clean up the glow plug holes since they took a bit of effort to thread in and they're easily accessible while the injectors are removed.

We will see what kind of shape they are in and what they can do to fix them up.

Also ordered an M10x1.25 tap to clean up the glow plug holes since they took a bit of effort to thread in and they're easily accessible while the injectors are removed.

Last edited:

I happened to be driving the Kubota dealer today so I stopped in and grabbed the copper washer seals for when the injectors come back.

I was going to start cleaning up the area around the injectors and clean up the threads for the glow plugs but it's raining here.

I was going to start cleaning up the area around the injectors and clean up the threads for the glow plugs but it's raining here.

The Diesel injection shop called this afternoon and said they're ready for pickup.

I don't think I'll make it there after work before they close but I'll try to get someone to pick them up for me so I can install them on the weekend.

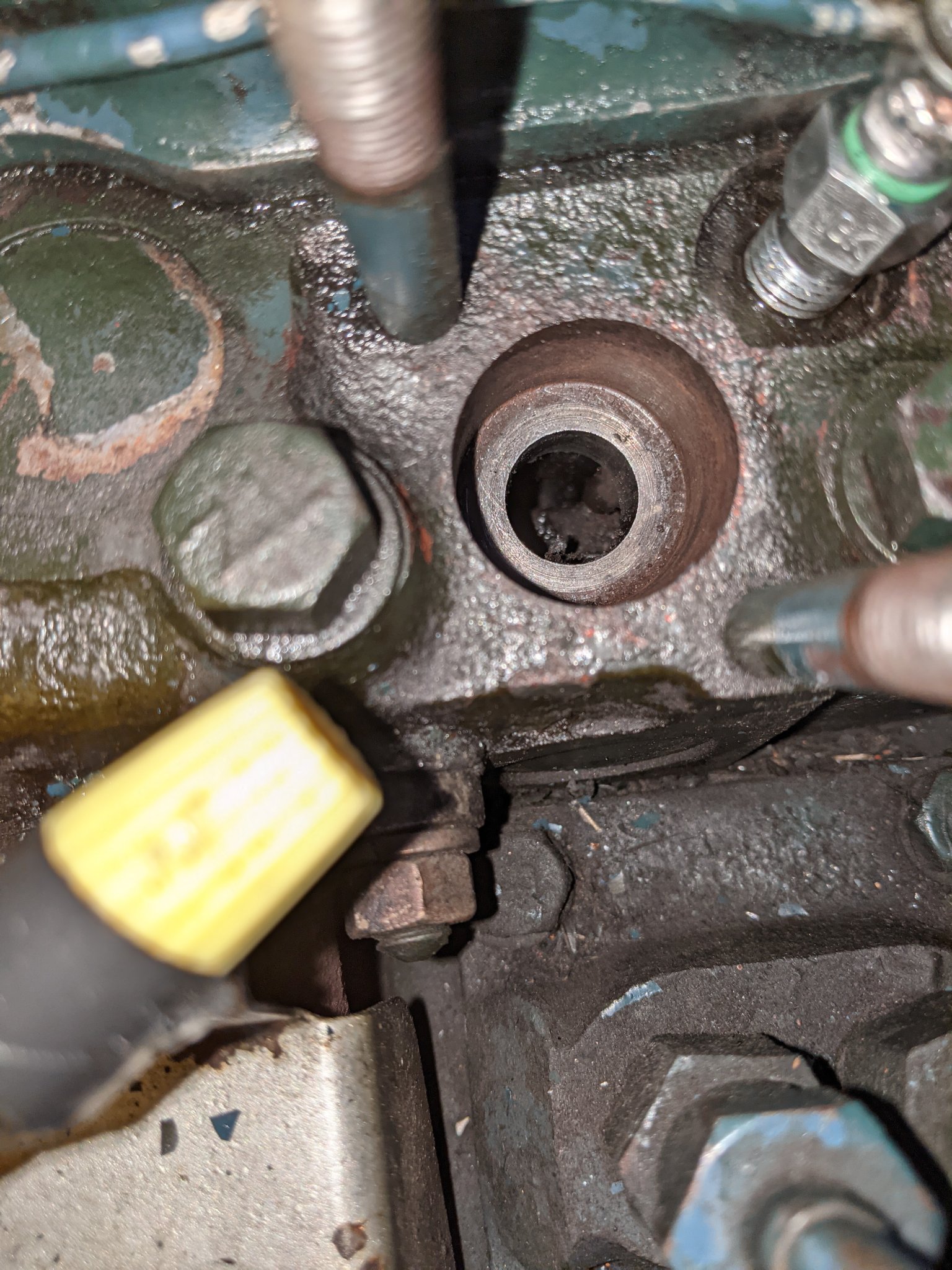

In the meantime tonight I cleaned up the seats where they go and cleaned up the threads for the glow plugs with the tap.

The glow plugs now thread in by hand until they bottom out.

I don't think I'll make it there after work before they close but I'll try to get someone to pick them up for me so I can install them on the weekend.

In the meantime tonight I cleaned up the seats where they go and cleaned up the threads for the glow plugs with the tap.

The glow plugs now thread in by hand until they bottom out.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Good call. I'll do that before I install the injectors.Put anti seize on the glow plugs.

Would it hurt to put a thin coat around the body of the injectors as well?

Obviously not on the seating surfaces but the part that goes into the head?

I was thinking about using my shop vac and an adapter that I have that looks like about the same diameter as the injector hole to suck out any bits of crud that might have fallen in there during this undertaking.

I'd turn it the shop vac on and give it a few rotations of the crank by hand.

Shouldn't hurt anything I don't think.

The radiator side cylinder looks pretty dirty in there from what I can see.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Anti seize on the injector really won't help much as they don't thread into the head they have hold downs.Good call. I'll do that before I install the injectors.

Would it hurt to put a thin coat around the body of the injectors as well?

Obviously not on the seating surfaces but the part that goes into the head?

I was thinking about using my shop vac and an adapter that I have that looks like about the same diameter as the injector hole to suck out any bits of crud that might have fallen in there during this undertaking.

I'd turn it the shop vac on and give it a few rotations of the crank by hand.

Shouldn't hurt anything I don't think.

The radiator side cylinder looks pretty dirty in there from what I can see.

fried1765

Well-known member

Equipment

Kubota L48 TLB, Ford 1920 FEL, Ford 8N, SCAG Liberty Z, Gravely Pro.

They only charged 5% "GST"?They even included the new copper gaskets from Kubota.

Another great service from a local company.

No provincial tax in Alberta?

fried1765

Well-known member

Equipment

Kubota L48 TLB, Ford 1920 FEL, Ford 8N, SCAG Liberty Z, Gravely Pro.

As I am sure you are aware, much of the dominion is paying an absurd 13-15% HST.Nope no PST here.

It seems like everytime the oil prices drop there's rumblings of bringing one in but so far so good.