We’ll that’s exactly the challenge I need to avoid completely half-assing this project. Thanks!Bending moments, shear forces, yada yada.

Looks like you know the conceptual considerations and trade offs. Be sure to share some pictures of what you end up with.

Multi-Metal Rust Risk? Should I just weld this sucker?

- Thread starter keith204

- Start date

It’s nothing you can’t undo or revise if you needed to.We’ll that’s exactly the challenge I need to avoid completely half-assing this project. Thanks!

The first tractor fab job I did a couple decades ago went a little south. I got to the do it again. Actually it was the first and last time I actually needed to break out the engineering handbook to evaluate the internal bending moment capacity of the structural section I selected. I typically go with the old adage of “When in doubt, hell for stout.”

Runs With Scissors

Well-known member

Equipment

L2501 TLB , Grappel, Brush Hog, Box Blade, Ballast box, Forks, Tiller, PH digger

Looks great man!

I also agree that you have great fab skills.

As previously suggest a few drainage holes should solve any water collection problems.

I tend to try and paint my fasteners, and do "touch up" every once in a while, just to keep the rust at bay for as long as possible.

When I was an aircraft mechanic, corrosion was a huge factor and we religiously 'touched up" anything that needed it. I continue the practice "to this day" on my own equipment.

Nice vivid pics too....

Edit: I also agree you do not have a "dis-similar" metal problem.

I also agree that you have great fab skills.

As previously suggest a few drainage holes should solve any water collection problems.

I tend to try and paint my fasteners, and do "touch up" every once in a while, just to keep the rust at bay for as long as possible.

When I was an aircraft mechanic, corrosion was a huge factor and we religiously 'touched up" anything that needed it. I continue the practice "to this day" on my own equipment.

Nice vivid pics too....

Edit: I also agree you do not have a "dis-similar" metal problem.

I used gas. Haven't used flux wire in quite a while.Ah yes, I spotted you & this project on a secondary binge today! Nice work and good point. Did you flux mig that?

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

My vote. Paint and bolt it on.

That way it's easier to remove when you decide that 'Version 2.0' is better ! BTDT.

What you may find is that any real weight on the receiver will bend it down. Say a trailer loaded with rocks and you hit 3 bumps in a row.....

Agree that while you do have different metals, corrosion won't be an issue . Don't use 'powder coat' paint ! Looks pretty but ONE small slice, cut,nick and it WILL let water under the skin of plastic, rust WILL form and it only gets worse from then on. Use an epoxy primer and real paint.

That way it's easier to remove when you decide that 'Version 2.0' is better ! BTDT.

What you may find is that any real weight on the receiver will bend it down. Say a trailer loaded with rocks and you hit 3 bumps in a row.....

Agree that while you do have different metals, corrosion won't be an issue . Don't use 'powder coat' paint ! Looks pretty but ONE small slice, cut,nick and it WILL let water under the skin of plastic, rust WILL form and it only gets worse from then on. Use an epoxy primer and real paint.

Good points all around. Below are pics from the initial tests. Sure enough, now that I SEE it and USE it, I have a long list of things to make it "proper"My vote. Paint and bolt it on.

That way it's easier to remove when you decide that 'Version 2.0' is better ! BTDT.

What you may find is that any real weight on the receiver will bend it down. Say a trailer loaded with rocks and you hit 3 bumps in a row.....

Agree that while you do have different metals, corrosion won't be an issue . Don't use 'powder coat' paint ! Looks pretty but ONE small slice, cut,nick and it WILL let water under the skin of plastic, rust WILL form and it only gets worse from then on. Use an epoxy primer and real paint.

Anyway, update:

^ is it obvious I didn't calculate bolt lengths?

^ 8" drop seemed to be the most natural height, but it also creates an undesirable lever for rotational forces. Maybe I can get over the heebie-jeebies? Or maybe I can just add support arms?

Green is prob sufficient, and would allow me to cut off those wonky wide bolts. Hmmm..... I'll try to forget about it for a while! But feel free to drop some ideas or wise counsel into the comments.

If a magnet sticks to it all...weld it.

The sheet metal of the 1260 won't hold much, so don't go crazy with trailer weight

The sheet metal of the 1260 won't hold much, so don't go crazy with trailer weight

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

mods for version 2.0.....

extend the receiver tubing forward to overlap the steel 'beam' that has the LP label

drill two holes front left, rear right of the extension

use U-bolts to secure the extension to the 'beam'

cut of excess u-bolt threads

extend the receiver tubing forward to overlap the steel 'beam' that has the LP label

drill two holes front left, rear right of the extension

use U-bolts to secure the extension to the 'beam'

cut of excess u-bolt threads

Looking good. Yea, probably ought to fix the length of that center bolt to stick out a couple thread beyond the face of the nut.

You think about putting a piece of round stock in the acute angle between the bottom of the horizontal plate and the top of the channel? Then you could weld up that gap and it’d stiffen the hell out of the assembly relative to the potential “twisting” action caused by the hitch.

But in the end this is for a B so you won’t likely ever have more than 500 lbs (maybe 200 lbs) of tongue weight on it. So anything you do, it will probably more than adequate. When in doubt, hell for stout.

You think about putting a piece of round stock in the acute angle between the bottom of the horizontal plate and the top of the channel? Then you could weld up that gap and it’d stiffen the hell out of the assembly relative to the potential “twisting” action caused by the hitch.

But in the end this is for a B so you won’t likely ever have more than 500 lbs (maybe 200 lbs) of tongue weight on it. So anything you do, it will probably more than adequate. When in doubt, hell for stout.

Last edited:

Ahhh - the "plate" is a triangular contraption w/ some angle iron & a bunch of ribs welded inside. That's not really shown in the pics. Does that kind of accomplish what you're talking about?You think about putting a piece of round stock in the acute angle between the bottom of the horizontal plate and the top of the channel? Then you could weld up that gap and it’d stiffen the hell out of the assembly relative to the potential “twisting” action caused by the hitch.

Edit: here you can see the angle iron sticking out to get the gist:

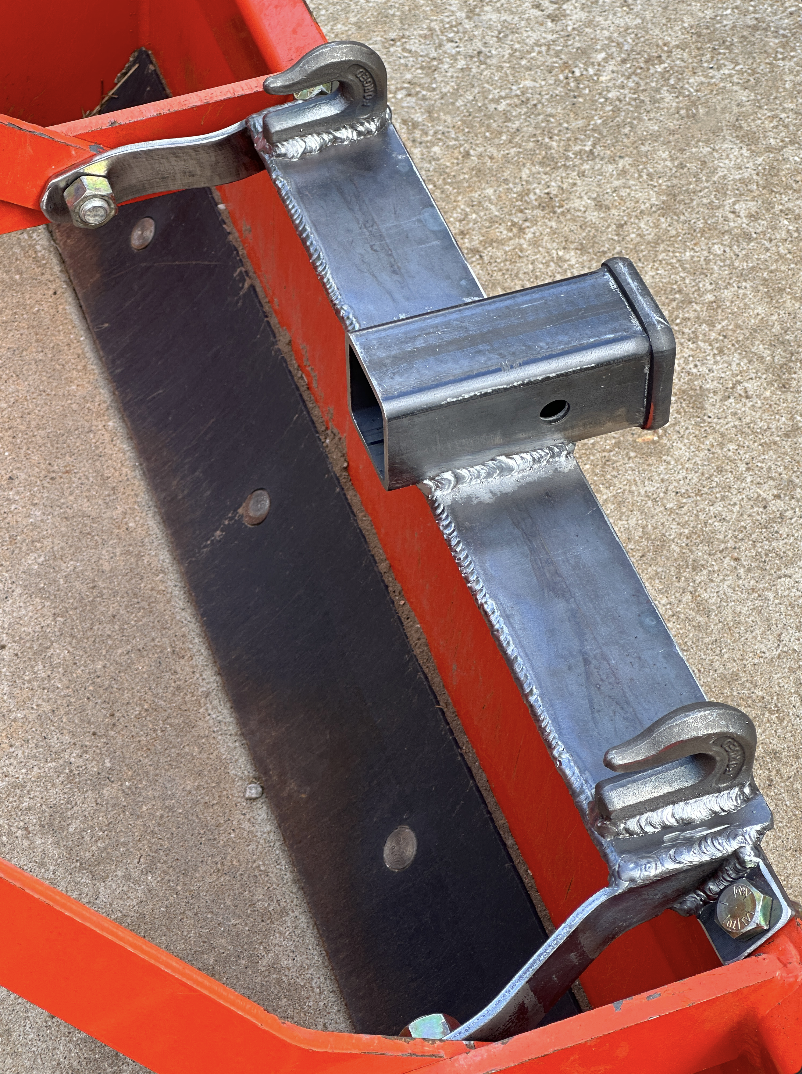

The heebie jeebies became serious... Since I plan on using the hooks to drag heavy rocks around (heavier than the bucket can lift) occasionally, I decided to beef up the support on the ends, which were previously pulling against the BB weld. @06B3030 and @GreensvilleJay got me thinking...maybe there's a solid spot on the tractor to hook up to.....

All I had to do was become unafraid of my Harbor Freight Compact Bender.

While I still don't know how to predictably use the thing, I got the curves I was looking for.

Bonus: I cut off the end of the angle iron, and welded on some thicker, gusseted tabs that surround the whole screw

Chamfering was necessary to clear the BB welds

But I feel a lot better about those 1" grade 8 bolts being involved

Thanks for helping me think through this! Now, I'm 100% confident that my welds will be the first thing to break!

All I had to do was become unafraid of my Harbor Freight Compact Bender.

While I still don't know how to predictably use the thing, I got the curves I was looking for.

Bonus: I cut off the end of the angle iron, and welded on some thicker, gusseted tabs that surround the whole screw

Chamfering was necessary to clear the BB welds

But I feel a lot better about those 1" grade 8 bolts being involved

Thanks for helping me think through this! Now, I'm 100% confident that my welds will be the first thing to break!

Damn you upped you game significantly. That is one heck of an improvement. Those bends, that’s money. No way I could do that.The heebie jeebies became serious... Since I plan on using the hooks to drag heavy rocks around (heavier than the bucket can lift) occasionally, I decided to beef up the support on the ends, which were previously pulling against the BB weld. @06B3030 and @GreensvilleJay got me thinking...maybe there's a solid spot on the tractor to hook up to.....

All I had to do was become unafraid of my Harbor Freight Compact Bender.

View attachment 111589

While I still don't know how to predictably use the thing, I got the curves I was looking for.

Bonus: I cut off the end of the angle iron, and welded on some thicker, gusseted tabs that surround the whole screw

View attachment 111590

Chamfering was necessary to clear the BB welds

View attachment 111594

But I feel a lot better about those 1" grade 8 bolts being involved

View attachment 111591

Thanks for helping me think through this! Now, I'm 100% confident that my welds will be the first thing to break!

NICE JOB! That will definitely help!

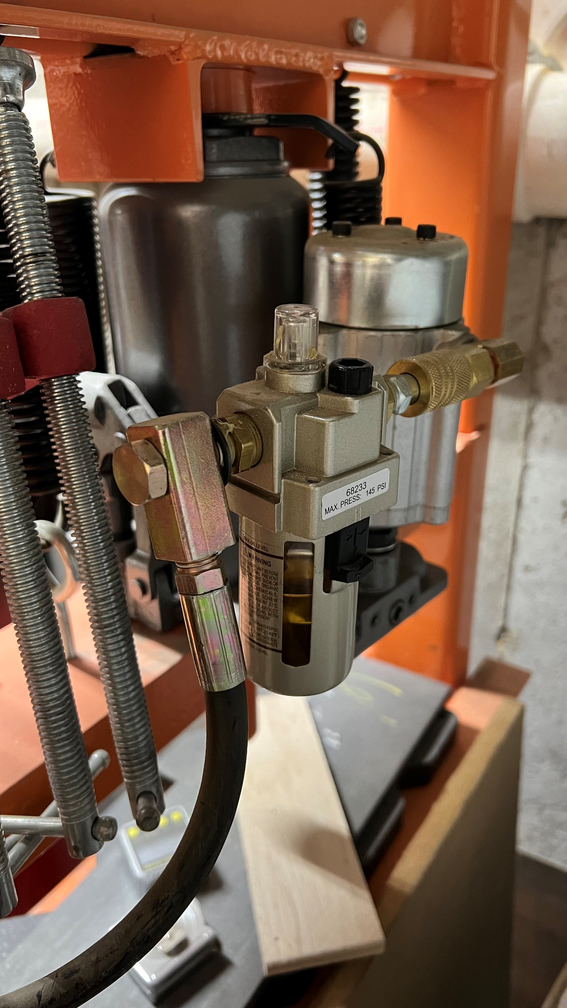

I have a HF 20 Ton Press that I upgraded with an air jack. I made a brake for it, and it's been awesome! I've bent some pretty heavy stock.

I have a HF 20 Ton Press that I upgraded with an air jack. I made a brake for it, and it's been awesome! I've bent some pretty heavy stock.

Runs With Scissors

Well-known member

Equipment

L2501 TLB , Grappel, Brush Hog, Box Blade, Ballast box, Forks, Tiller, PH digger

Damn it man!!!!NICE JOB! That will definitely help!

I have a HF 20 Ton Press that I upgraded with an air jack. I made a brake for it, and it's been awesome! I've bent some pretty heavy stock.

View attachment 111616

View attachment 111617

View attachment 111618

View attachment 111619

View attachment 111620

That's a sweet brake.

I have been meaning to make one of those.

Now I feel like a "damned slacker"

Last edited:

Just put your "Nikes" on and..."JUST DO IT"!!!! LOLDamn it man!!!!

That's a sweet brake.

I have been meaning to make one of those.

Now I feel like a "damned slacker"

whoa! What kind of footprint, realistically, does that take up? And how easily moveable is it?NICE JOB! That will definitely help!

I have a HF 20 Ton Press that I upgraded with an air jack. I made a brake for it, and it's been awesome! I've bent some pretty heavy stock.

View attachment 111616

View attachment 111617

View attachment 111618

View attachment 111619

View attachment 111620

Suddenly I’m re-analyzing my space using this technique

It isn't that big. I have it on casters so it's easy to move around.whoa! What kind of footprint, realistically, does that take up? And how easily moveable is it?

Suddenly I’m re-analyzing my space using this techniqueto see if I can a way to squeeze it in.

Here's the specs...