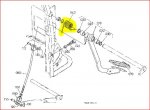

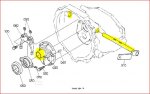

My neighbor is having an issue with his clutch not returning after he lets out on it. He can reach down with his foot and pull it up, but it won't come up on its own. I think it's probably the pressure plate or possibly the throw out bearing getting hung up. I'm thinking it will have be split. I checked all the linkage.

Last edited: