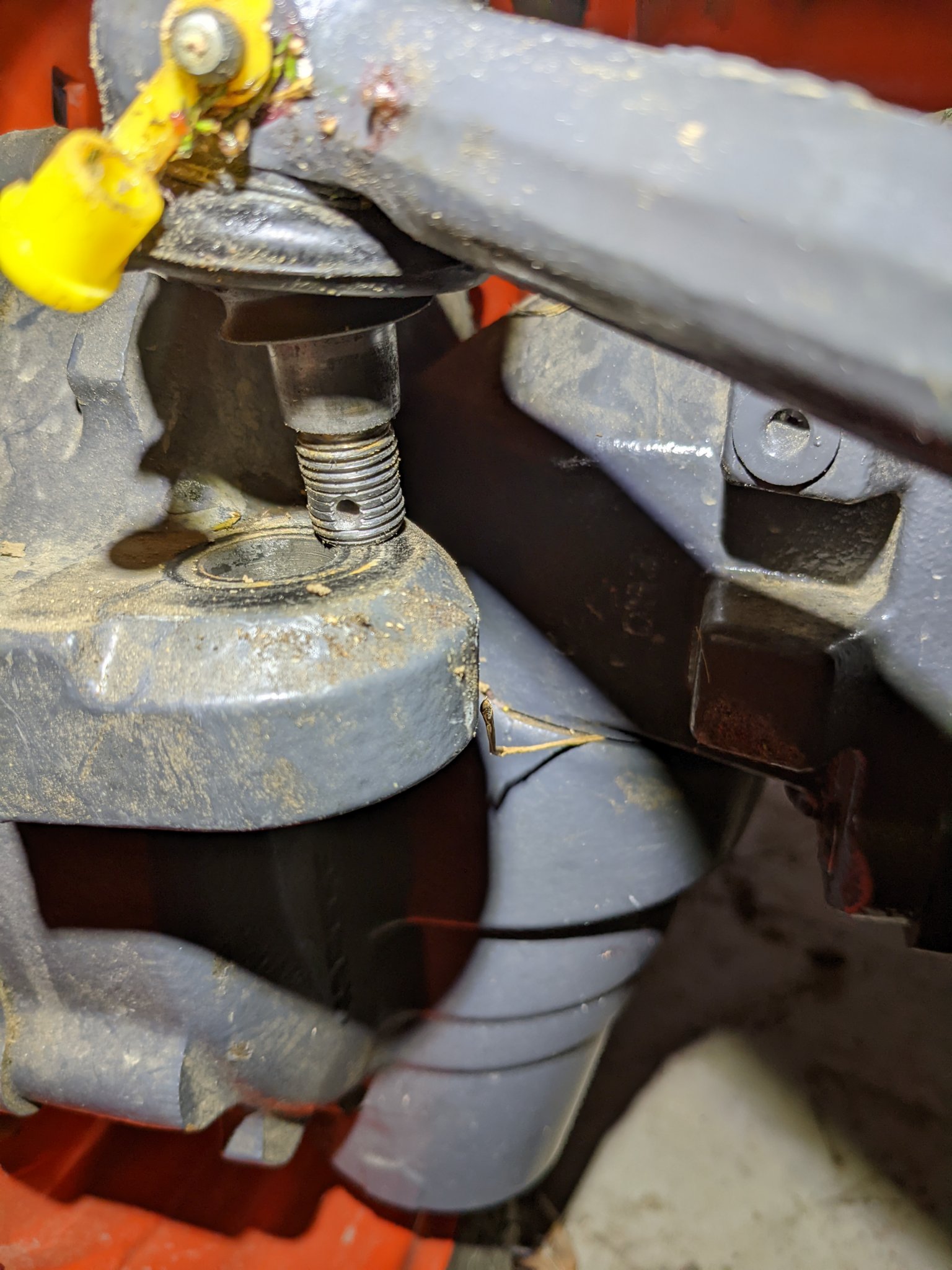

Well I popped my tie rod end out going over a rock like tree stub. It looks like it popped the bolt off as the threads are no longer straight. Does anyone have this part number for a 2501? I pushed it back in and went really slow to get back to the garage. I guess I need to order a parts manual. Didn't think I needed one yet with a brand new tractor. It also popped my loader stand pin out, that's an easier fix though.

L2501 tie rod end

- Thread starter DDCD

- Start date

How old is the tractor? It appears to be the right side ( sitting in seat facing forward)? I believe from reading here, the L are shipped with the right side axle hub not attached, dealer installs after uncrating it during prep. Doesnt appear it was installed correctly (and should have had a cotter pin to keep the nut from backing off.

ken erickson

Well-known member

Equipment

B7100 hst, 2650 front mount snowblower, L2501 hst qa loader

That was my first thought also as it happened to me with a brand new L2501How old is the tractor? It appears to be the right side ( sitting in seat facing forward)? I believe from reading here, the L are shipped with the right side axle hub not attached, dealer installs after uncrating it during prep. Doesnt appear it was installed correctly (and should have had a cotter pin to keep the nut from backing off.

I don’t see how hitting anything with it would cause that (if it was properly installed). Its hard to see in pic on my phone, but it almost looks like the nut was crossthread on and not ran up all the way. Im not by my L. What does the other side look like?Is it possible to push it up with enough force to strip the bolt off, even with pin installed?

I made the dealer come out and redo the checklist when I bought it. Not sure if this was checked though.

Last edited:

The more I think about it I agree. I think it would bend before a nut and cotter pin that large pops off. I'll get another picture shortly.I don’t see how hitting anything with it would cause that (if it was properly installed). Its hard to see in pic on my phone, but it almost looks like the nut was crossthread on and not ran up all the way. Im not by my L. What does the other side look like?

Going back, I believe this is further evidence the tie rod end wasn’t tight.

Those marks appear to be from it moving in the hole when turning the wheels.

Those marks appear to be from it moving in the hole when turning the wheels.

Left side looks good and like it was painted at the factory.The more I think about it I agree. I think it would bend before a nut and cotter pin that large pops off. I'll get another picture shortly.

Attachments

-

429.6 KB Views: 66

ken erickson

Well-known member

Equipment

B7100 hst, 2650 front mount snowblower, L2501 hst qa loader

The dealer sent a tech out after the nut fell off and tie rod end fell off . After replacing it , it was determined the original tech that had set the tractor up neglected to set and adjust the toe in. That might be something you may need to check if it has not been done already.