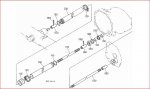

I was plowing some snow with the front end loader and about 30 minutes in I noticed I had no traction anymore. It was obvious that only my rear wheels were spinning and lost 4WD. I tried backing up and making sure it was in 4WD and all I could hear is a little whirring noise (similar to a gear not fully engaged). I lifted the front end up and it only barely moved the front wheels with the tires off the ground. When I spin one tire, I can hear the gears turn and the other tire barely moves the opposite direction. Everything feels smooth so I think it must be broken between the transmission and the driveshaft to the front pinion. Is there a common place to look for? I hear that there could be a coupler shaft with a roll pin that could have slid out that might have caused it. I never heard any loud noises or feel and crunchiness/broken gears.

Last edited: