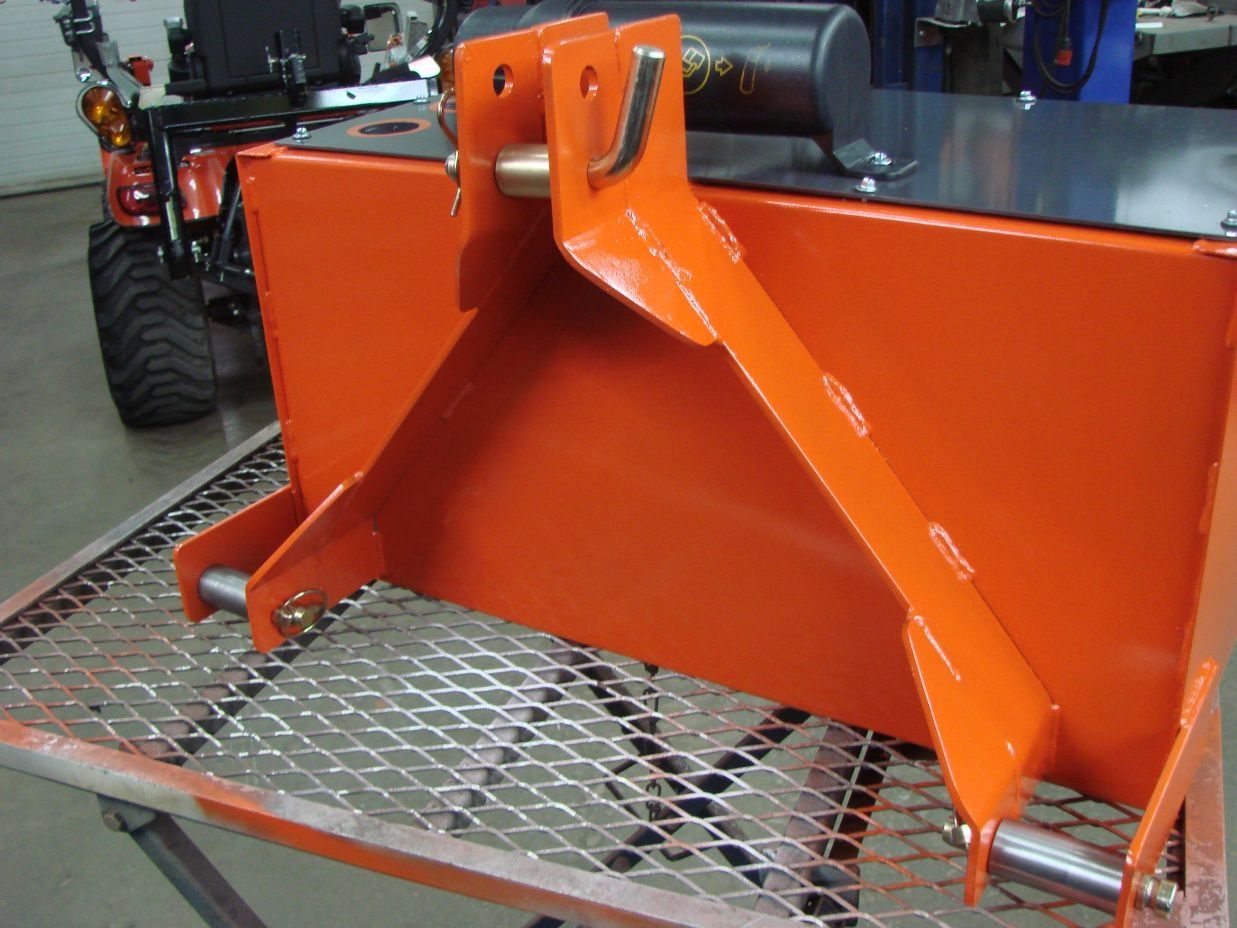

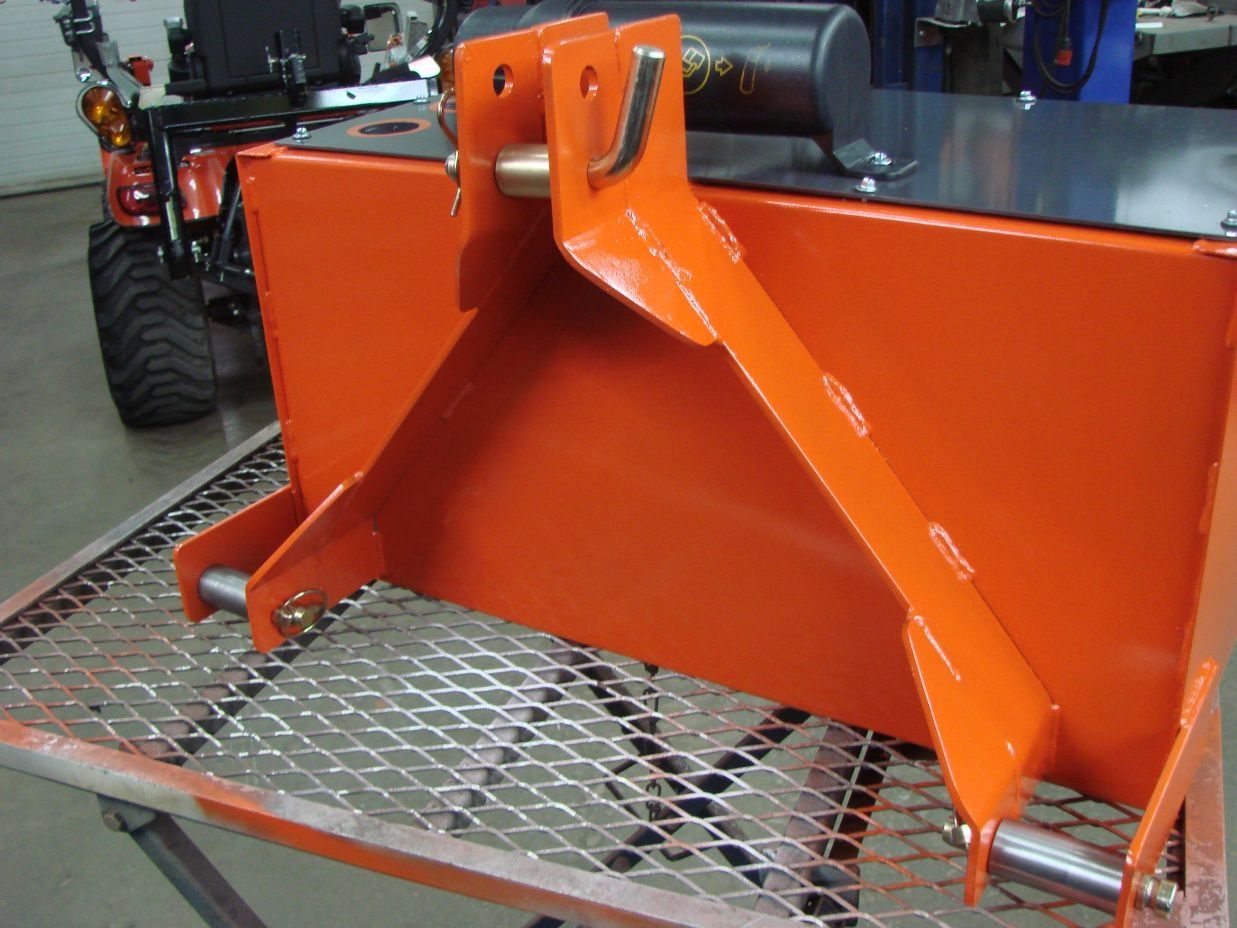

kubota ballast box converted to quick hitch compatible

- Thread starter kubotaguy

- Start date

gpreuss

New member

Lifetime Member

Equipment

L3200DT w/FEL, K650 Backhoe, 5' Rotary, 40" Howard Rotavator, 6' Rhino blade

the "design" wasn't without some shortcomings. on the first pass with the components that hook up to the quick hitch, when I put about 200 pounds of sand and some steel weights in the box, I could not get the quick hitch low enough to allow it to be hooked up. :-( I have a friend who is an elevator technician and he gave me several (6 or 7) elevator counter weights each weighing about 100-110 pounds each. So my second "ECO" which is short for Engineering Change Order, was to bolt the two box beams to the bottom of the ballast box. With that, I got an unanticipated side benefit in that it pretty much makes the ballast box "tip over" proof. I've got a considerable amount of arthritis in my neck and it is hard to turn my head enough to get a good look at lining up the hitch with the ballast box. Over the years, I have tipped over the ballast box 2 or 3 times even with just 1/4 inch of misalignment. So.. with the box beams it just doesn't tip and if I am mis-aligned a bit it just scoots the ballast box along the ground without tipping it. The whole thing isn't perfect, but it gets the job done for me.

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Looks great. Those QH's are great and even better now that your ballast box fits it. I had to do something similar. Nice job.

my initial design also had a 2nd shortcoming. I originally put about 400 pounds of sand and 9 of the elevator weights into the ballast box. With the weight of the ballast box, sand, and elevator weights, I was at approx 1500 pounds of ballast. Twas a bit too much weight. I sprung the lower side plates (with the bushings) out a bit taking them out of alignment by about 10 degrees. So, I bent them back with my fine adjustment tool (an 8 pound sledge hammer) and then welded an extra 3/8 thick plate across the side plates.

That pretty much solved the problem. I'm a retired engineer from the big yellow and of course I have the utmost respect for a "true mechanical" design which would allow a finite element analysis of all structural components prior to fabricating any steel to begin with. But in a home shop, those kinds of computer tools aren't available to me. my point, "Structural engineering is a great asset"

That pretty much solved the problem. I'm a retired engineer from the big yellow and of course I have the utmost respect for a "true mechanical" design which would allow a finite element analysis of all structural components prior to fabricating any steel to begin with. But in a home shop, those kinds of computer tools aren't available to me. my point, "Structural engineering is a great asset"

Last edited:

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Ah having things engineered takes all the fun out if it  now you got to do things like us fellows, by the seat of your pants and hope it turns out right

now you got to do things like us fellows, by the seat of your pants and hope it turns out right

I had to do a few mods on my ballast box as well and I got 400 lbs in it.

Started out with this pos.

Ended up with this

I had to do a few mods on my ballast box as well and I got 400 lbs in it.

Started out with this pos.

Ended up with this

Noting the great job, I am wondering why not make your own box? You certainly have that capability. Since I'm a CE I make a little use of that background, but do a lot of seat of pants building of stuff that works quite well for me. One detail that you used I would not do. I find too often that the attachment that I want to pick up is not on level ground. Then that top hook does not engage. My top hook sits on the shelves seldom used. Instead I put a link between the top of the quick hitch and the tool. If I put several holes in that link it takes care of the poor setting until I can get to better ground. Also with just the arm hooks set you can play with the height to get things hooked at the top, but with the Quick hitch hook there that is more difficult than as I do it. And those half inch bolts never seem to get over-loaded on my larger tractors with larger attachments.. Click on thumbnail for larger photo.

Attachments

-

93.8 KB Views: 941

Last edited:

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Noting the great job, I am wondering why not make your own box? You certainly have that capability. Since I'm a CE I make a little use of that background, but do a lot of seat of pants building of stuff that works quite well for me. One detail that you used I would not do. I find too often that the attachment that I want to pick up is not on level ground. Then that top hook does not engage. My top hook sits on the shelves seldom used. Instead I put a link between the top of the quick hitch and the tool. If I put several holes in that link it takes care of the poor setting until I can get to better ground. Also with just the arm hooks set you can play with the height to get things hooked at the top, but with the Quick hitch hook there that is more difficult than as I do it. And those half inch bolts never seem to get over-loaded on my larger tractors with larger attachments.. Click on thumbnail for larger photo.

Well that's a good question on the building of my own box and perhaps I should have but the box I had was given to me. It was built defective, as in one of the lower pin mounts weren't welded straight so once I got it I started getting a few ideas and went to work and did the mods on it. I've built other attachments for it as well plus I use the QA with our chipper and it's easy to attach anything to it.

I have no issues using the QA with the top hook. Actually if I had to remove the top hook to use it I probably wouldn't use the QA at all. Kind of defeats the purpose of it in my mind if you have to start lining up a pin instead of a hook.

Putting an attachment on our QA is just a matter of backing up to the implement and raising the 3pt hitch and it's hooked up. Nothing easier than that. Once the height is set for the QA top hook I've never needed to move it. Not sure what you mean by " I'm a CE"? Civil engineer?

Great job! It's crazy that Kubota will not follow the ASAE Category 1 Standard S278.6 for quick-attach hitches when they build these boxes. You just shouldn't have to cut and weld a brand new attachment for your tractor.

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

So true. Its kind of crazy but it is what it is. To tell the truth I enjoyed doing that little projectGreat job! It's crazy that Kubota will not follow the ASAE Category 1 Standard S278.6 for quick-attach hitches when they build these boxes. You just shouldn't have to cut and weld a brand new attachment for your tractor.

That one was taken this past spring. This one I snapped just for you a few minutes ago. The only time I've seen snow was on CNN. We had a few flurries and they are calling for a little tomorrow but I'm not expecting much.Paul I know those have got to be old pictures, cause by now everything your way is WHITE,,,,lol

Attachments

-

52.7 KB Views: 525

Wildfire:

Nice photos. In reply to question, yes I am a civil engineer, age 85 now. Still get out there in the mud now and then, self employed.

As to not using the top hook for the QH, several of the attachments I have used, usually for a larger tractor than the BX, have the pin there set back inside a support, so that there is no way that the top QH hook will engage with a simple raising of the 3 pt..

Nice photos. In reply to question, yes I am a civil engineer, age 85 now. Still get out there in the mud now and then, self employed.

As to not using the top hook for the QH, several of the attachments I have used, usually for a larger tractor than the BX, have the pin there set back inside a support, so that there is no way that the top QH hook will engage with a simple raising of the 3 pt..

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

No. Please. I don't want snow. Not at least for this winterGee Im sorry Bud, Im sure we could get together and send you some of ours,,,And ya know every time I see that thing, I think about those handy dandy drink holders you put there

Well sir you have my respect. I got a long time friend who was a civil engineer. He's now retired but he hardly knew what a tire valve was so your leap years ahead of him. To be fair to him he's always relied on me for mechanical issues.Wildfire:

Nice photos. In reply to question, yes I am a civil engineer, age 85 now. Still get out there in the mud now and then, self employed.

As to not using the top hook for the QH, several of the attachments I have used, usually for a larger tractor than the BX, have the pin there set back inside a support, so that there is no way that the top QH hook will engage with a simple raising of the 3 pt..

I think it's only recently that implement manufactures are building their products that work and fit well on the new QA systems but when it comes to the sub compact machines it's hit and miss with them.

I to have to make sure that where ever I drop an implement I need to make sure the implement is level or it's a devil of a time to reconnect to the QA so your idea would be perfect in those none level cases.

Thanks for posting. Enjoyed seeing it.

My hydraulic top link makes the already easy job of picking up a implement with the qh even easier.

And Mr. Paul, did I miss your post about adding forks to the bx or did you slip that one in there. lol

And Mr. Paul, did I miss your post about adding forks to the bx or did you slip that one in there. lol

Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

I think I've posted on them before. Those buggers cost me as much as I paid for the ones on the Grand LMy hydraulic top link makes the already easy job of picking up a implement with the qh even easier.

And Mr. Paul, did I miss your post about adding forks to the bx or did you slip that one in there. lol

I just made mods to my Ballast box and thought I would share the pictures. The welder charged me $10.00 for material and I gave the welder $20.00! That's it and it works great. I primed with Rustoleum and then used Kubota spray match the color.

Pix 1 - a look at the original placement of the ears from the factory.

Pix 2 - Welder added a 1/2 inch piece of steel and from center hole of original to center hole of new add on is 4 inches.

Pix 3 - view from other side

Pix 4 - View head on

5 - Just to show what I used on the top pin.

Pix 1 - a look at the original placement of the ears from the factory.

Pix 2 - Welder added a 1/2 inch piece of steel and from center hole of original to center hole of new add on is 4 inches.

Pix 3 - view from other side

Pix 4 - View head on

5 - Just to show what I used on the top pin.

Attachments

-

70 KB Views: 745

-

77.2 KB Views: 699

-

32.7 KB Views: 700

-

33.9 KB Views: 945

-

34.1 KB Views: 1,054