The Kubota B6000 is capable of controlling auxiliary single action hydraulics with the same lever used for the rear lift arms. This seems like a pretty clean and simple way of adding aux hydraulics to me. Using an integration block or plumbing more valves inline might be more versatile but also much more complex.

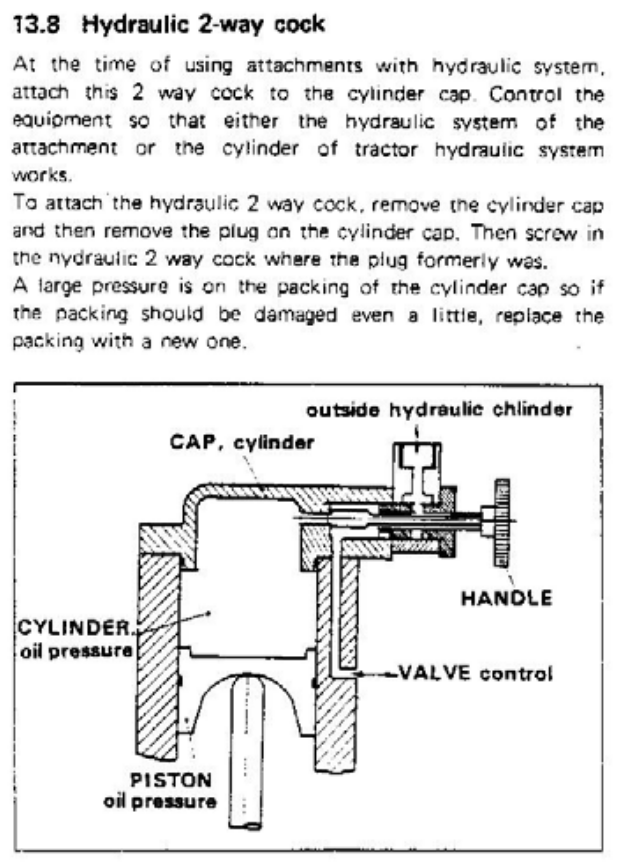

Here are the relevant parts of the operating and service manuals that mention this.

Here are photos so you can see how it works. The hydraulic fluid comes up the small hole on the side of the aluminium housing and into the steel cylinder cap. Usually the aux hydraulics connection has a plug in it, so the fluid is forced back down into the lift arms cylinder. When the two way cock is installed and screwed in, it will block the fluid going down to the lift arms cylinder and force it all to go out the aux connection.

I assume that since the onboard or aux hydraulics will be completely blocked off when the valve is set to control the other one, it will retain its position until you switch back to it.

I can't find any part numbers, photos or more info about the two way cock. Can anyone help? I wonder if one could be machined up after taking the measurements. Or maybe a whole new cylinder cap could be made that was designed to have an off the shelf two way valve added.

Here are the relevant parts of the operating and service manuals that mention this.

Here are photos so you can see how it works. The hydraulic fluid comes up the small hole on the side of the aluminium housing and into the steel cylinder cap. Usually the aux hydraulics connection has a plug in it, so the fluid is forced back down into the lift arms cylinder. When the two way cock is installed and screwed in, it will block the fluid going down to the lift arms cylinder and force it all to go out the aux connection.

I assume that since the onboard or aux hydraulics will be completely blocked off when the valve is set to control the other one, it will retain its position until you switch back to it.

I can't find any part numbers, photos or more info about the two way cock. Can anyone help? I wonder if one could be machined up after taking the measurements. Or maybe a whole new cylinder cap could be made that was designed to have an off the shelf two way valve added.