Heddenonin

New member

Equipment

b2910, king kutter brush hog, land pride finish deck, box blade, snow plow, rake

Hi all. I have a b2910. Had it for several years with little to no issues at all. Just a few weeks ago I started it and, within a few seconds, it died. I changed the fuel filter at that time and it seemed to resolve. I was able to run it until a couple days ago. At that time, I started it and within a few seconds, it died. Now, I can immediately restart it and then it dies again. It just keeps following that pattern. I've had to refuel a few times in the past couple weeks, so I'm not thinking there is old fuel in the tank. However, I have treated the fuel in the tank as well.

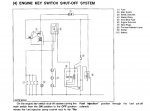

I've also checked the voltage supplied to the fuel stop solenoid. I'm getting a range of 10 - 11 volts. I did attempt to bypass the solenoid by connecting jumper wires to ground and the battery positive terminal. At that time, I heard the solenoid 'click'. But, when I plug the solenoid into the harness and turn the ignition key on, I don't hear the same 'click'.

I am a shade-tree mechanic. I don't know if I'm barking up the wrong tree with the solenoid. I've also thought about the safety interlock switches. However, if a switch were the culprit, the tractor shouldn't even turn over?

I would appreciate any assistance with this issue.

Tom

I've also checked the voltage supplied to the fuel stop solenoid. I'm getting a range of 10 - 11 volts. I did attempt to bypass the solenoid by connecting jumper wires to ground and the battery positive terminal. At that time, I heard the solenoid 'click'. But, when I plug the solenoid into the harness and turn the ignition key on, I don't hear the same 'click'.

I am a shade-tree mechanic. I don't know if I'm barking up the wrong tree with the solenoid. I've also thought about the safety interlock switches. However, if a switch were the culprit, the tractor shouldn't even turn over?

I would appreciate any assistance with this issue.

Tom